New England Volvo CE dealer acquires new network territory

04 April 2023

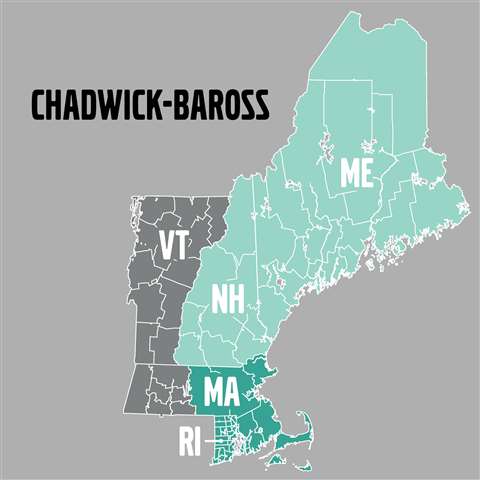

Chadwick-BaRoss’ existing territory (light green) now expands into eastern Massachusetts and Rhode Island (dark green). Photo by Chadwick-BaRoss.

Chadwick-BaRoss’ existing territory (light green) now expands into eastern Massachusetts and Rhode Island (dark green). Photo by Chadwick-BaRoss.

In acquiring the Volvo and SDLG assets of Woodco Machinery on April 1, Chadwick-BaRoss, which has operated in Maine and New Hampshire as a member of the Volvo Construction Equipment network, will now expand its territory into eastern Massachusetts and Rhode Island.

“We thank the Benard family, who owned and operated Woodco Machinery, for their four-decade partnership with Volvo Construction Equipment, and we appreciate their service and commitment as a Volvo dealer,” said Stephen Roy, president of Region North America, Volvo CE.

Woodco had served as the exclusive Volvo CE dealer for eastern Massachusetts and Rhode Island until Chadwick’s acquisition, and the latter company is now the exclusive dealer in the territory.

“I’m excited to grow our relationship with Chadwick-BaRoss,” Roy said. “They offer exceptional experience, presence and customer service, and I know that their strong performance will continue in their newly expanded territory.”

Chadwick, which has provided equipment to the New England customers for almost 100 years, will offer a full lineup of Volvo equipment and services at its already-established locations and future sites.

“Volvo is a highly respected name among our customers, and we’ve had great success with Volvo products in Maine and New Hampshire,” said Jim Maxwell, president of Chadwick-BaRoss. “I’m excited to bring Volvo machines and Chadwick-BaRoss service and support to our new customers in Massachusetts and Rhode Island.”

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

CONNECT WITH THE TEAM