Multiple Pump Drive meets drill rig challenge

03 August 2023

Transfluid Industrial & Marine is offering the MPD (Multiple Pump Drive), which it asserts is capable of addressing the needs of drilling rig manufacturers affected by engine design changes required to meet modern emissions standards.

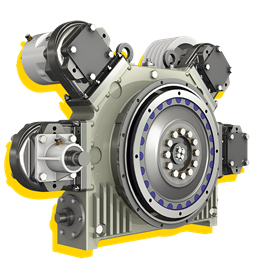

The MPD split drive module is available in all SAE standard input/output arrangements for engines up to 1,850 hp. (Photo: Transfluid)

The MPD split drive module is available in all SAE standard input/output arrangements for engines up to 1,850 hp. (Photo: Transfluid)

According to the company, as engine manufacturers strove to meet emissions requirements, many familiar features of the previous generations were “casualties of the design process.” One example was the reduction of pump pad provisions provided on the diesel engine, Transfluid noted, which affected drilling rig manufacturers who depended on these pads to drive hydraulic pumps for their top drive.

Because the flywheel of the diesel engine is needed to provide power to a multi-speed transmission to run the draw works, a separate hydraulic power unit would need to be used to run the pumps, said Transfluid, which would significantly increase the price of the drilling rig.

To address this challenge, the company introduced its MPD split drive module, which is designed to sandwich between the main diesel engine and transmission. It has an integrated flexible coupling on the input side and an SAE standard flywheel and housing on the output side. Gear-driven PTO heads provide multiple pump pads for mounting pumps, while the output flywheel provides adequate power transfer to drive larger transmissions.

With this solution, even the most hydraulically impaired engines can cost effectively drive multiple implements, Transfluid stated. It added that hydrostatic equipment can also benefit from the MPD’s design by allowing each pump to have its own head and be installed without stacking.

The module is available in all SAE standard input/output arrangements for engines up to 1,850 hp. Up to four total PTO heads are available, with as many as eight total pump pads ready for mounting.

Other benefits include:

- Pads are not limited to only hydraulic pumps and are able to drive any SAE standard equipment, with adapter kits available for various input configurations.

- Stub shaft PTO attachments are available for the heads to allow pulley drives (for a side-mounted compressor or generator), as well as oil or air-actuated clutches for engaging or disengaging individual pads.

- The pump circuit for providing pressure to the clutches can be mounted onboard the unit to allow the customer to engage the clutch with a 12 or 24V dc signal.

- The cooling for the unit can be routed through the customer’s existing heat exchanger.

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

CONNECT WITH THE TEAM