Liebherr’s new digital clearance monitor

24 February 2022

Liebherr’s bearing clearance monitoring system (BCM) is designed to eliminate the need for service personnel to use manual measurements to determine the condition of slewing bearings in large equipment. (Photo: Liebherr)

Liebherr’s bearing clearance monitoring system (BCM) is designed to eliminate the need for service personnel to use manual measurements to determine the condition of slewing bearings in large equipment. (Photo: Liebherr)

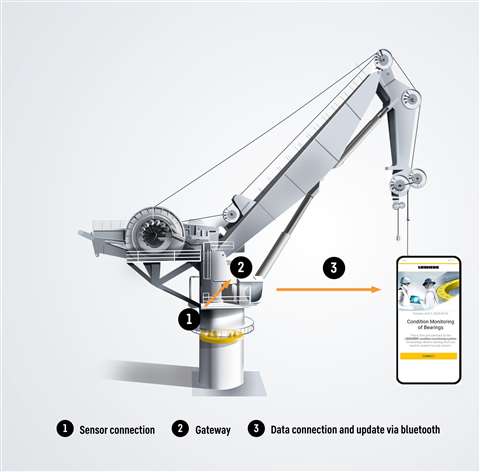

Liebherr-Component Technologies AG has developed a digital condition monitoring system for slewing bearings, used in equipment such as mining, material handling and maritime equipment.

The new bearing clearance monitoring (BCM) system is designed to provide optimum remote monitoring of the slewing bearings and can measure bearing wear in axial and radial directions, as well as tilting clearance. The system ensures flexibility in measurement, reduced downtime, lower maintenance costs and higher personal protection, the company said.

(Photo: Liebherr)

(Photo: Liebherr)

“A distinct disadvantage of all common wear measurement methods is the necessity for service technicians to mount dial gauges or other measuring devices directly on the slewing bearing in the danger zone under the excavator or other machines,” said Wolfram Halder, product manager of the slewing bearings business unit. “The Liebherr BCM system makes this unnecessary, as the measuring devices are already permanently installed on the bearing.”

The BCM can also save diagnostic time and expense, Halder said. Currently, machine operators commission third-party service providers to measure the bearing clearance. “With digital maintenance for slewing bearings by Liebherr, measurements can be carried out at any time outside the danger zone, independently of external service providers,” Halder said.

The sensor connection box receives the data from the sensors attached to the slewing bearing and supplies the entire BCM system with power. The gateway stores the sensor data and updates for the BCM. This allows using the system autonomously even in regions without data connection, such as remote mines, the company said. A direct connection via Bluetooth makes the measurement process possible from a safe distance and without a network connection.

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

CONNECT WITH THE TEAM