Caterpillar celebrates 130 years at Wisconsin plant

08 September 2023

Bucyrus Steam Shovel and Dredge Company, acquired by Caterpillar in 2011, opened its manufacturing facility in South Milwaukee, Wis., in 1893 in a move designed to improve and expand its production facility. Production was relocated to the site to increase manufacturing efficiency of the company’s core large machinery, including rope shovels, draglines and dredges.

Bucyrus dredges were used in such historic earthmoving projects as the New York State barge canal enlargement project. (Photo: Caterpillar)

Bucyrus dredges were used in such historic earthmoving projects as the New York State barge canal enlargement project. (Photo: Caterpillar)

Since that time, Bucyrus-produced earthmoving equipment has proven a major contributor to monumental excavation projects throughout the world. “Dredges were used as part of the California gold rush, and shovels were a part of the vast Mesabi Iron Ranges,” recalled Shawn Paap, commercial manager for Cat Electric Rope Shovels (ERS). “The New York State barge canal enlargement project, the largest U.S. earthmoving project between 1902-1912, also used Bucyrus dredges.”

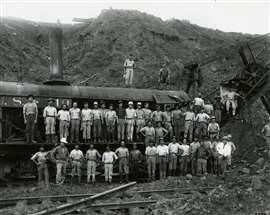

Seventy-seven of the company’s 40- to 50-ton steam-powered shovels produced at the South Milwaukee plant also played a significant role in building the Panama Canal. When combined with shovels produced by Marion Steam Shovel Company, a Bucyrus heritage company, 101 of the 102 shovels used in the project were from Bucyrus.

World War II saw virtually 100% of the company’s entire output from 1942 to 1945 devoted to the war effort. Post-war, the company embarked on a $2 million project to increase plant capacity by 20%. By the middle of the 20th century, Bucyrus was a global company with an expanded product offering, and more than 74,000 Bucyrus machines had been produced and used in over 166 countries, Caterpillar noted.

Seventy-seven Bucyrus steam-powered shovels, all produced in South Milwaukee, played a significant role in building the Panama Canal. (Photo: Caterpillar)

Seventy-seven Bucyrus steam-powered shovels, all produced in South Milwaukee, played a significant role in building the Panama Canal. (Photo: Caterpillar)

Over the last 130 years, more than 32,000 machines have been produced at the South Milwaukee location, and to this day, massive Cat electric rope shovels are being produced at the plant. Today’s Cat 7495 and 7495HF models used for the mining industry began as steam-powered railroad shovels. Then, as early as 1917, Bucyrus pioneered the use of electricity as a power source, with the advent of a DC electrical power system in 1919 ushering in the start of today’s modern ERS design. This was later revolutionized with the transition to less complicated AC electric motors.

“AC drive motors were simpler, lasted longer, required less maintenance, worked faster and more efficiently and delivered greater power than DC motors,” said Mike Haws, technical steward for Cat Electric Rope Shovels. “The introduction of insulated gate bipolar transistor (IGBT) fuseless technology led to the evolution into digital gate turnoff (GTO) systems. And a partnership with Siemens in the 1970s put Bucyrus on the cutting edge of AC drive technology, pushing drive system availability upward to 99%.”

More than 200 Caterpillar electric rope shovel models have been produced in South Milwaukee since the 2011 acquisition of Bucyrus. (Photo: Caterpillar)

More than 200 Caterpillar electric rope shovel models have been produced in South Milwaukee since the 2011 acquisition of Bucyrus. (Photo: Caterpillar)

Since acquiring the Bucyrus product line in 2011, the Cat ERS product has continued to be elevated to the next level of safety, productivity and reliability, Caterpillar said, by making the machines safer, easier to access and maintain, better performing under extreme conditions, integrating the latest technology and ensuring higher availability. More than 200 of the 134.4-ton (120 tonne) capacity ERS models have been produced in South Milwaukee, initially under the Bucyrus name and now as Caterpillar, with today’s models incorporating technologies, such as the Integrated Technology Package (ITP) and Operator Assist Package (OA) introduced earlier this year.

“We are proud of our long heritage in South Milwaukee, the impact the equipment produced at this location has had on the global market over the last 130 years, and the talented and dedicated team continuing the tradition of excellence in the production and support of Cat electric rope shovels and draglines,” said Jeremy Niedens, facility manager – South Milwaukee for Caterpillar.

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

CONNECT WITH THE TEAM