Why sustainability demands are boosting hydraulic fluid technology

12 November 2021

Lubrizol develops hydraulic fluid technology aimed to increase performance and efficiency

As hydraulic components and systems continue to evolve to meet increased demands for efficiency, productivity and sustainability, another critical component of the system – hydraulic fluid – is often overlooked. Yet hydraulic fluids need to keep pace with the demands of higher operational speeds and pressures, increasing use of electronics, greater precision and accuracy of operation, and more compact systems that result in smaller reservoir capacities.

And like the pumps, motors, cylinders and valves through which it flows (and lubricates), hydraulic fluid must deliver reliable performance and longevity, without unforeseen failures that result in machine downtime.

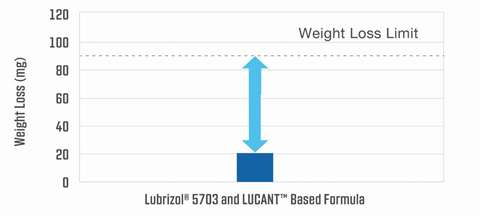

Lubrizol’s hydraulic fluid performance demonstrated under the Eaton 35VQ vane pump test.

Lubrizol’s hydraulic fluid performance demonstrated under the Eaton 35VQ vane pump test.

With all that in mind, Lubrizol, the Wickliffe, Ohio-based specialist in fluid additives and technology, said it has taken steps toward development of a total mobile hydraulic fluid solution that combines established, durable additive chemistry with a shear-stable, energy efficient performance polymer.

Industrial products at Lubrizol Corp

“Our testing demonstrates how this unique combination can help diesel equipment achieve higher profitability via reduced fuel and energy costs,” said Blayne McKenzie, Strategic Technology manager, Industrial Products at Lubrizol Corp. He added that the formulation improves productivity by maintaining equipment in reliable working condition and helps reduce energy consumption – and associated exhaust emissions – without compromising the lubricant’s durability.

High-performance hydraulic fluid

Key to establishing a high-performance hydraulic fluid is finding balance among a range of desired performance characteristics. “A complete fluid must demonstrate the necessary performance across a range of industry-standard bench and OEM hardware tests,” McKenzie noted.

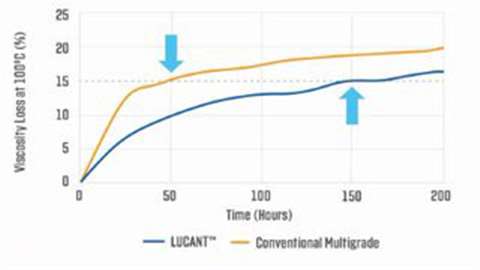

Lubrizol’s hydraulic fluid performance per the 200 Hour KRL Shear Test.

Lubrizol’s hydraulic fluid performance per the 200 Hour KRL Shear Test.

To achieve that balance, Lubrizol combined an established hydraulic additive package (Lubrizol 5703) that carries a broad range of industry- and OEM-specific approvals with a new performance polymer. The polymer, Lucant, was specifically developed to help hydraulic fluids meet the challenges of modern equipment operating conditions.

Durability performance, as measured by the Eaton 35VQ vane pump test, is shown in Figure 1. The results showed that durability was categorically maintained across the relevant testing cycles, as the end-of-test weight loss measurement fell well within the established test limit.

“This kind of performance is particularly important when considering transitioning from a mono-grade hydraulic fluid to a multi-grade option, as the stay-in-grade shear-stability of the formulation’s viscosity modifier must be maintained,” McKenzie said. “Our testing showed that the right performance polymer can deliver appropriate multi-grade low temperature performance without compromising lubricant durability.

“In addition, the performance polymer can also contribute to extra protection when compared with conventional multi-grade viscosity modifiers.”

Figure 2 shows 200-hour KRL bearing shear data shown by the same fluid, formulated with Lubrizol 5703 and Lucant. “The tested fluid remains safely below the 15% viscosity loss threshold for three times as long as a conventional multigrade hydraulic fluid,” McKenzie said. “This kind of enhanced shear performance can contribute to significantly higher protective capabilities, enabling the relevant mobile hydraulic equipment to perform reliably even under the most strenuous conditions seen in today’s vehicles.”

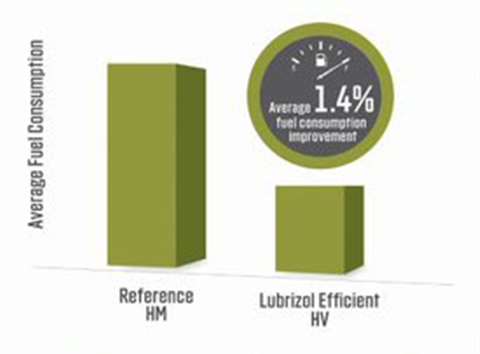

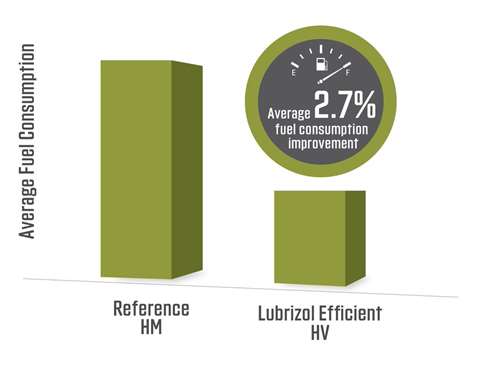

Field trial results demonstrating the fuel savings capabilities of Lubrizol’s hydraulic fluid solution for a wheel loader operating in the summer (left) and the winter (right).

Field trial results demonstrating the fuel savings capabilities of Lubrizol’s hydraulic fluid solution for a wheel loader operating in the summer (left) and the winter (right).

Enhanced Energy Savings

A complete hydraulic fluid solution designed for the needs of modern vehicles can also help reduce fuel consumption in mobile equipment, helping contribute to greater profitability for fleet owners and other end users.

To demonstrate the capability of its fuel solution, Lubrizol commissioned a mobile field trial utilizing a wheel loader. As shown in Figure 3, the trial generated diesel fuel savings of 1.4 to 2.7% depending on the seasonal usage and ambient temperature.

Though relevant field testing shows how a new hydraulic fluid can deliver real-world benefits, Lubrizol sought additional confirmation in a controlled lab environment. “Laboratory conditions can help eliminate many of the constraints and variables inherent in field testing,” McKenzie said, “and can help further validate performance.”

Lubrizol tested the hydraulic solution in its in-house Energy Efficiency Rig, a system designed to mimic mobile hydraulic equipment. Originally conceived to replicate a skid-steer loader, the system incorporates all of the critical components of a hydraulic system and is unique in its ability to evaluate total system efficiency, McKenzie said.

In the rig, an off-the-shelf commercial piston pump feeds a hydraulic circuit, complete with hydraulic pipes, hoses, and valves, ultimately powering a hydraulic piston motor. Supplementary hardware components can also be varied as needed.

Basic efficiency testing was carried out over a specified condition set intended to capture diverse duty cycles and hydraulic system requirements. Outfitted with flow, pressure, and temperature sensors, the rig offers Lubrizol an opportunity to carry out extensive hydraulic efficiency research, helping in the development of forward-looking solutions.

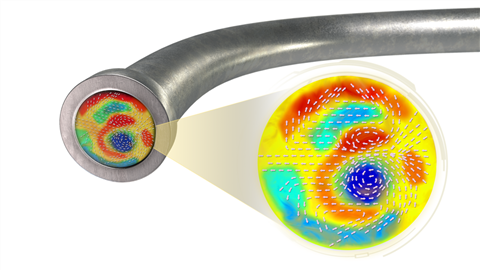

Lucant mitigates losses as hydraulic fluid travels through bends in hydraulic systems.

Lucant mitigates losses as hydraulic fluid travels through bends in hydraulic systems.

The test rig was first utilized to confirm the efficiency gains exhibited by Lucant and Lubrizol 5703 in field trials. Figure 5 depicts total system efficiency data for typical ISO 46 hydraulic fluids, where the Lucant performance polymer fluid delivers efficiency gains over both a monograde (3.8% improvement) and a conventional multigrade (1.6% improvement) fluid.

Lubrizol efficiency Gains

Both field and lab trials demonstrate that the combination of Lubrizol 5703 and the Lucant performance polymer can deliver significant efficiency gains.

Lucant is engineered to provide significant performance improvements compared to conventional hydraulic viscosity modifiers. Its molecular structure enables it to mitigate losses generated as the fluid travels around through a variety of valves, filters, and other non-linear hardware flow paths found in mobile hydraulic systems. Figure 6 shows a secondary flow field (indicated by the arrows) as a fluid exits a 90° bend.

Lubrizol tested its hydraulic fluid solution in its in-house Energy Efficiency Rig, a system designed to mimic mobile hydraulic equipment.

Lubrizol tested its hydraulic fluid solution in its in-house Energy Efficiency Rig, a system designed to mimic mobile hydraulic equipment.

Lucant can reduce the intensity of such secondary flow vortices by forming flexible chains of small diameter with respect to their overall contour length. It offers a large extensibility parameter that gives viscoelastic behavior. Conventional viscosity modifiers have long side chains and comparatively short backbones that prevent tight coiling and reduce flexibility, resulting in reduced extensibility and no detectable viscoelastic component. The viscoelastic chains of Lucant store, and thus extract, energy from the coherent vortices, leading to their decay. This contributes to a greater ability for hydraulic fluid formulated with Lucant to deliver significant efficiency gains, the company said.

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

CONNECT WITH THE TEAM