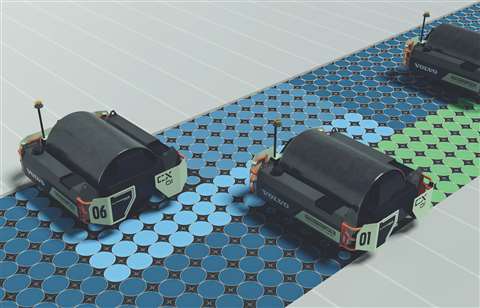

Volvo CE’s autonomous asphalt compactor concept

29 September 2021

Volvo CE’s CX01 single-drum asphalt compactor concept

Volvo CE’s CX01 single-drum asphalt compactor concept

Volvo Construction Equipment (Volvo CE) has unveiled its CX01 single-drum asphalt compactor concept at The Utility Expo in Louisville, Kentucky, US.

The CX01 concept utilises one vibratory asphalt compactor drum that’s actually two independent halves (called a split-drum) kept upright by a self-balancing control system.

Capable of being operated either by remote-control or entirely autonomously, the machine is also fitted with both a diesel engine and an energy storage system, making it a flexible electric hybrid solution. It can be operated in diesel-only, hybrid or fully electric modes.

“While the CX01 is a conceptual product, the research and development that have gone into it will benefit customers in other ways,” said Justin Zupanc, head of the asphalt compaction development team, Volvo CE.

Volvo CE says that by redesigning the compactors themselves, the operator is removed from the unit – reducing exposure to vibration, noise, dust and other associated environmental conditions – and freed up to autonomously control a fleet of CX units working together to compact asphalt surfaces.

A fleet of these units deployed on larger jobs could work together and communicate not only between each CX unit but also to other pieces of equipment on the site. The machines could survey the jobsite, report on the conditions of the materials, things like density, temperature and passes, and determine when and where to compact.

Rolling pattern, weight and number of rollers can all be adjusted to match the width, thickness and speed of paving operation, providing a complete paving solution for whatever the job might be, from light infrastructure to highway construction.

The CX01 can be matched with Volvo’s existing Co-Pilot system so that all work can be handled remotely via a touchscreen interface. In addition, it uses GPS position tracking to monitor job performance and help customers better hit their productivity targets.

While the CX01 concept has been purely an exploration, some learnings could be applied to future products.

“Remote control and autonomous operations are areas of focus for us in R&D. Also, while the low-friction water reduction coating on the drum shell is theoretical, it could be a huge benefit on larger machines to decrease the amount of water needed,” Zupanc added.

“It is exciting to think how the theories showcased on the CX01 could be realised on compaction production units in the future.”

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

CONNECT WITH THE TEAM