Tenneco adds hydrogen to engine testing capabilities

02 February 2023

Tenneco has established new test facilities for hydrogen-powered internal combustion engines at its Powertrain test centers in Burscheid, Germany, and Ann Arbor, Mich. The two test cells specifically dedicated to hydrogen ICEs enhance the company’s globally integrated ICE test capabilities, supporting original equipment (OE) engine and vehicle manufacturers as they decarbonize the ICE.

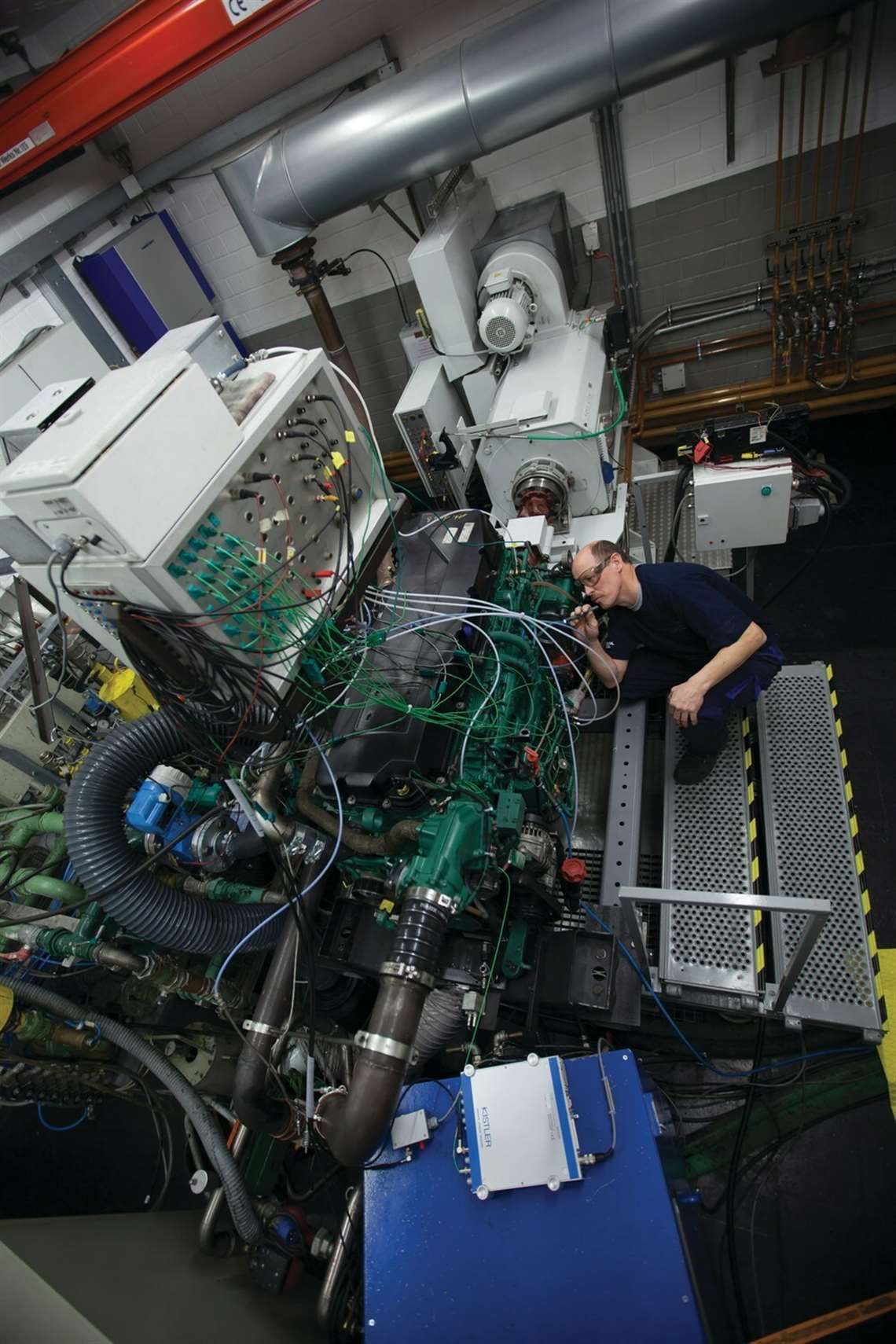

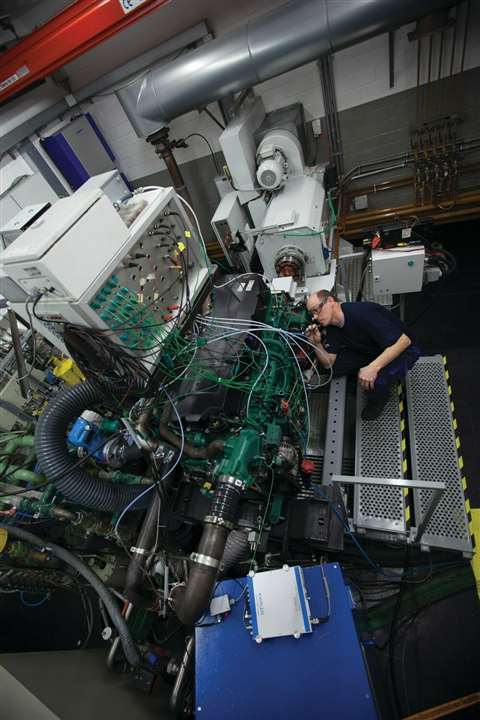

Preparation of a hydrogen engine test cell at Tenneco’s Advanced Technology Center in Burscheid, Germany. (Photo: Tenneco)

Preparation of a hydrogen engine test cell at Tenneco’s Advanced Technology Center in Burscheid, Germany. (Photo: Tenneco)

By adding H2 engine testing, Tenneco said it is positioned to provide technology solutions that can help accelerate the reduction of carbon emissions of future combustion engines to achieve global climate goals faster.

“We support a pragmatic approach of complementary technologies that provide solutions for different transportation sectors,” said Stefan Rittmann, vice president, Engineering with Tenneco’s Powertrain business group. “We contend it’s not combustion-engine technology causing greenhouse gas emissions in the product-use phase – it is the fuel used in the ICE that defines the vehicle emissions. Therefore, green hydrogen, which is produced from renewable energies and carbon-free by nature, offers great potential for cleaner transportation, especially in sectors difficult to electrify, such as heavy-duty commercial vehicles, on- and off-highway applications and the industrial and marine sectors.”

As a global supplier of engine components – including pistons, piston rings, bearings, seals and gaskets, valves, valve seats and guides, and ignition devices – Tenneco said it will leverage its comprehensive ICE expertise in various hydrogen and alternative fuel project partnerships with engine and vehicle manufacturers. Tenneco’s new test cells can support manufacturers in their H2 ICE concepts, testing prototype engines and components for durability, wear, emissions, fuel-efficiency and performance.

“Using our knowledge about the influence of hydrogen on the combustion process and on the Powertrain Control Unit (PCU), we are able to address hydrogen-specific challenges like pre-ignition and H2-slip into the crankcase as well as the influence on tribology and materials,” said Dr. Steffen Hoppe, Powertrain’s director Technology Rings & Liners, Tenneco. “The R&D from our H2 test benches, along with support from our simulation tools like PRiME3D, can accelerate the development process and help our customers go to market with highly efficient H2 combustion engines faster.”

Tenneco’s new H2 ICE test facilities provide a broad range of engine measurement capabilities, including:

- Light and heavy-duty engine testing up to 700 kW (938 hp).

- Eddy current and ac dynamometers testing.

- ECU connectivity, calibration and tuning.

- Dynamic engine operation simulating driving cycles.

- H2 supply up to 90kg/h at 50 bar pressure.

- H2 concentration measurement (exhaust and blow-by path).

- Combustion analysis.

- Emissions testing for HC, CO, CO2, NOX, FSN and gaseous emissions

- Particulate number (PN) count/PN size distribution and particulate matter (PM).

- Radioactive tracer for oil emissions.

- In-line oil consumption and oil emission analysis.

- Automated fuel map testing.

- Ignition parameter evaluation.

- Thermal shock testing.

- Precise real-time engine monitoring.

“Tenneco is dedicated to being a good corporate citizen; you see it in our operations and in our products,” said Troy Kantola, Powertrain’s Engineering director, Technical Services. “Our efforts to enhance our test sites reflect this in that now we are equipped to serve our customers’ aspirations to reduce or eliminate entirely fuel-related CO2 emissions as quickly as possible.”

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

CONNECT WITH THE TEAM