SpecSys, RVI offer range of services to equipment manufacturers

20 February 2020

Founded in 1997, Ritalka offers a full range of engineering and manufacturing services and has grown to more than 275 employees and 700,000 sq.ft. of facilities in eight locations in Minnesota, South Dakota and Wisconsin.

As a parent company, it covers a number of separate businesses, including SpecSys Inc. (Specialty Systems), an engineering and manufacturing service provider, and RVI Inc., which focuses on developing complex electronics and most recently wire harnesses for a wide range of clients, including mobile off-highway equipment.

When it acquired the former Caterpillar plant in Prentice, Wis., three years ago, Ritalka said its plan was to increase its reach beyond forestry equipment, and it has done just that. Forestry equipment is no longer built inside its walls – at least for the time being – but currently in its place is equipment for material handling, construction and mining.

Factory support for OEMs

“With Prentice, we got a turnkey facility,” Mark Jaspersen, vice president of Account Management for SpecSys, which runs that factory as well as plants in Watertown, S.D. and Granite Falls, Redwood Falls and New Ulm, Minn. “We’ve got all of the capabilities necessary to fabricate equipment there. We’ve got 17 different CNC machining centers, 30-plus welders, a paint booth and a full assembly team.

“For our customers, we make turn-key equipment and can handle anything from construction, forestry, oil and energy equipment to material handling, agriculture and mining. And, obviously, forestry equipment, as the Prentice name is synonymous with that market. We’re a resource for equipment manufacturers and offer another manufacturing facility for them to tap into.”

According to Jaspersen, the company partners with original equipment manufacturer (OEM) customers on an even deeper level, as well, from small specialty equipment builders to Fortune 100 companies.

“At any given time about a third of the projects we’re doing involve taking a napkin design from our client and doing the final design and print development,” he said. “We’ll use those prints and do the prototype build in whatever quantity they need for testing. We’ll also do the cycle testing and field testing.

“Another third of the work we do is taking our client’s prints and doing the fabrication through assembly build, where we’ve got no engineering content in there. We’re very capable of making products for our clients based on their design. For some clients, we just do the fabricating. They use us to solve their heartburn, to fill in areas where they are faced with time constraints.

The final third of the company’s work centers on its engineering department. “We can do the design work through print development or any portion in between. Then we turn the prints back over to our client and they build a prototype and go into production. We’ve got clients out there that just use us for FEA analysis, for example.”

According to the company, that work amounts to a total of 40,000 hours per month on the manufacturing end and 5000 hours per month in engineering services.

Wire harnesses

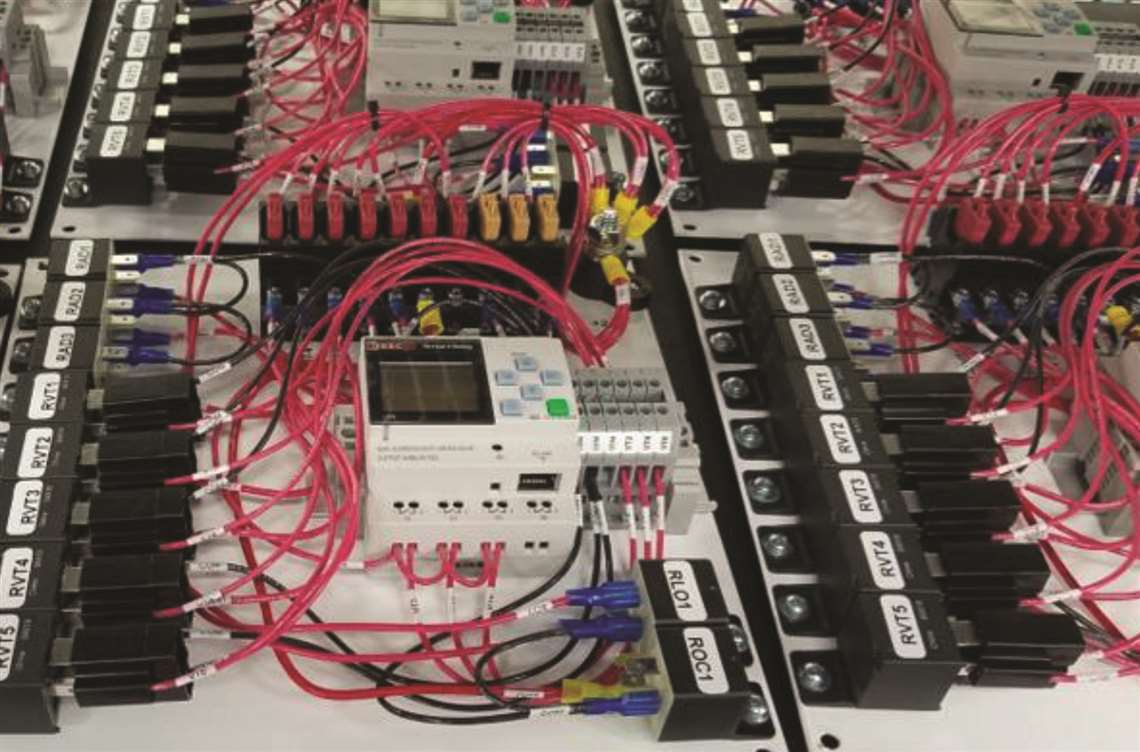

RVI has traditionally developed and built electronic repair and test equipment, work that for more than 30 years has required it to develop its own wire harnesses. Recently, it has expanded its product line to include wire harnesses for mobile off-highway equipment, covering the same markets as sister company SpecSys – and tapping into its engineering expertise whenever necessary. RVI has electrical and programming engineers on staff, as well.

“We’re working with manufacturers with small to mid-size volumes so we’re not trying to compete against the large automotive type of high-volume manufacturers,” said Todd Osman, president, RVI Inc. “That’s where we feel like we’re a good fit. We like to get involved in new product launches and help with designs early in the process.

“Some OEMs have been trying to do that harness work in-house yet and don’t have the resources available. What we’ve been finding is that a lot of our clients were treated really well by a wire harness manufacturer but now their supplier is only interested in large volumes. They can’t get the work done within the lead times the client needs. Companies are looking for alternative sources, and that’s how we have picked up a lot of our new clientele.”

With locations in Redwood Falls, Minn., and Watertown, S.D., RVI offers design, ISO process-controlled board layouts and crimping tools, testing, braiding and packaging. The company said it is a “single-point manufacturer with a proven tractor record of product management, from engineering prototypes through production releases.”

The wire harnesses continue Ritalka’s vertical integration goals.

“Even beyond wire harnesses, we’re also offering work on hydraulics and programming and control systems,” said Osman. “We can offer all the different packages that make up a complete system.”

See these companies at ConExpo booth S-83810

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

CONNECT WITH THE TEAM