Rolls-Royce wins award for sliding bearing technology

08 November 2021

Sliding bearings reduce fuel consumption by 1%

Sliding bearings reduce fuel consumption by 1%

Rolls-Royce has been awarded the Environmental Technology Prize from the Ministry of the Environment in Baden-Wüttemberg, Germany.

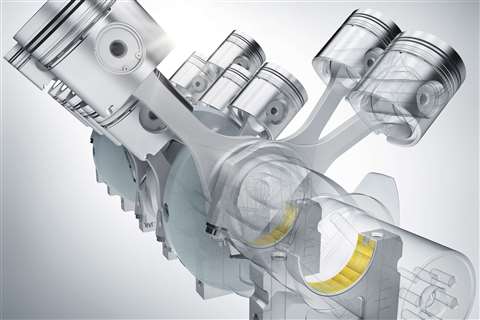

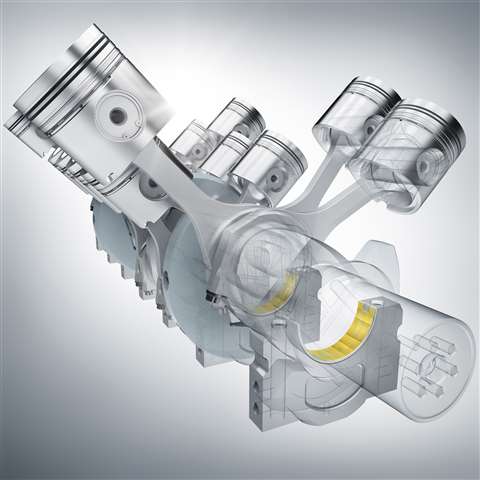

The OEM engine manufacturer received the award for its sliding bearings which feature in the mtu engines. The new feature is said to reduce fuel consumption by 1%.

The fuel saving is achieved by reducing friction between the bearing and crankshaft. This is achieved by furbishing the surface of the bearings with grooves which channel lubricant to create an anti-friction surface.

The additional lubricant can reduce friction by between 20% and 35%, dependent on operating mode.

The innovative bearing is the result of a collaborative effort between a small project team in Friedrichshafen, bearing manufacturer Miba, and the MontanUniversität Leoben in Austria.

“The technology behind sliding bearings is very mature and very well established and to genuinely improve it you need outstanding engineering expertise and innovative talent,” said Dr. Otto Preiss, COO and CTO at Rolls-Royce Power Systems.

“So we’re very proud that along with our partners, we’ve succeeded in developing an optimized metal slide bearing that can be installed in our engines without the need for further modification. With just one easy production step extra, a 1% reduction in fuel consumption can be achieved that not only lowers costs, but avoids emissions.”

mtu engines produced by Rolls-Royce will be fitted with the sliding bearing ‘in the near future’. Engines already in service will be retro-fitted with the feature. The technology will be marketed as an individual component by Miba AG.

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

CONNECT WITH THE TEAM