Rio Tinto first to fully convert open pit mine to renewable diesel

09 June 2023

Rio Tinto U.S. Borax Mine and mtu-powered truck in Boron, Calif. (Photo: Rio Tinto)

Rio Tinto U.S. Borax Mine and mtu-powered truck in Boron, Calif. (Photo: Rio Tinto)

Rio Tinto has converted the entire equipment fleet at its Boron mine in California from fossil fuel-based diesel to renewable diesel, reportedly making it the first open pit mine in the world to achieve this milestone.

“We are proud that our U.S. Borax operations have become the first open pit mine to operate a fleet running entirely on renewable diesel,” said Sinead Kaufman, chief executive, Rio Tinto Minerals. “This is an excellent example of what happens when internal and external partners collaborate toward a carbon reduction goal.”

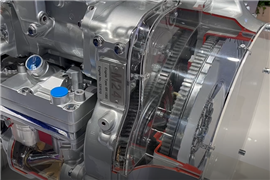

Rolls-Royce is supporting the mining company in its endeavor and has been testing mtu engines using hydrotreated vegetable oil (HVO) in dump trucks and wheel loaders since 2022. During the 2,000 hours of operation to date, engines run on the renewable diesel have been shown to deliver similar performance and reliability to fossil diesel, Rolls-Royce said.

Rolls-Royce conducted an initial trial in 2022 with a Borax dump truck, working in collaboration with fuel manufacturer Neste. Rio Tinto U.S. Borax used Neste MY Renewable Diesel during the trial – a fuel made from sustainably sourced, 100% renewable raw materials such as waste cooking oil and animal fat waste. The trial results showed that a dump truck powered by mtu engines running on renewable diesel had similar performance and reliability to dump trucks running on conventional fuel.

Based on these results, Rio Tinto U.S. Borax has continued to work with Rolls-Royce, Neste, the Environmental Protection Agency and the State of California to fully convert its on-site heavy equipment fleet to sustainable diesel by the end of May 2023. This conversion includes all heavy equipment on the site, from haul trucks to wheel loaders and even blasting equipment.

The switch to renewable diesel at the Boron mine is expected to reduce CO2 emissions by up to 45,000 tonnes per year, equivalent to annual emissions from about 9,600 cars. Other anticipated benefits of the switch include a reduction in particulate emissions of up to 40% in mobile applications and a reduction in nitrogen oxide emissions by an average of 8%. As a drop-in fuel, no changes are required to the existing diesel plant infrastructure and no engine hardware or software modifications are required.

“The conversion of the first open pit mine to HVO is an important milestone. We are pleased to be part of the energy transition at the U.S. Borax mine and partner with Rio Tinto,” said Cobus van Schalkwyk, director, Global Mining, at the business unit Power Systems of Rolls-Royce. “With further sustainable offerings, such as reman or re-motorization solutions for the vehicles or microgrids for energy supply, we are ready for the further future of the mines.”

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

CONNECT WITH THE TEAM