PSI Provides More Power For Power Generation

28 August 2020

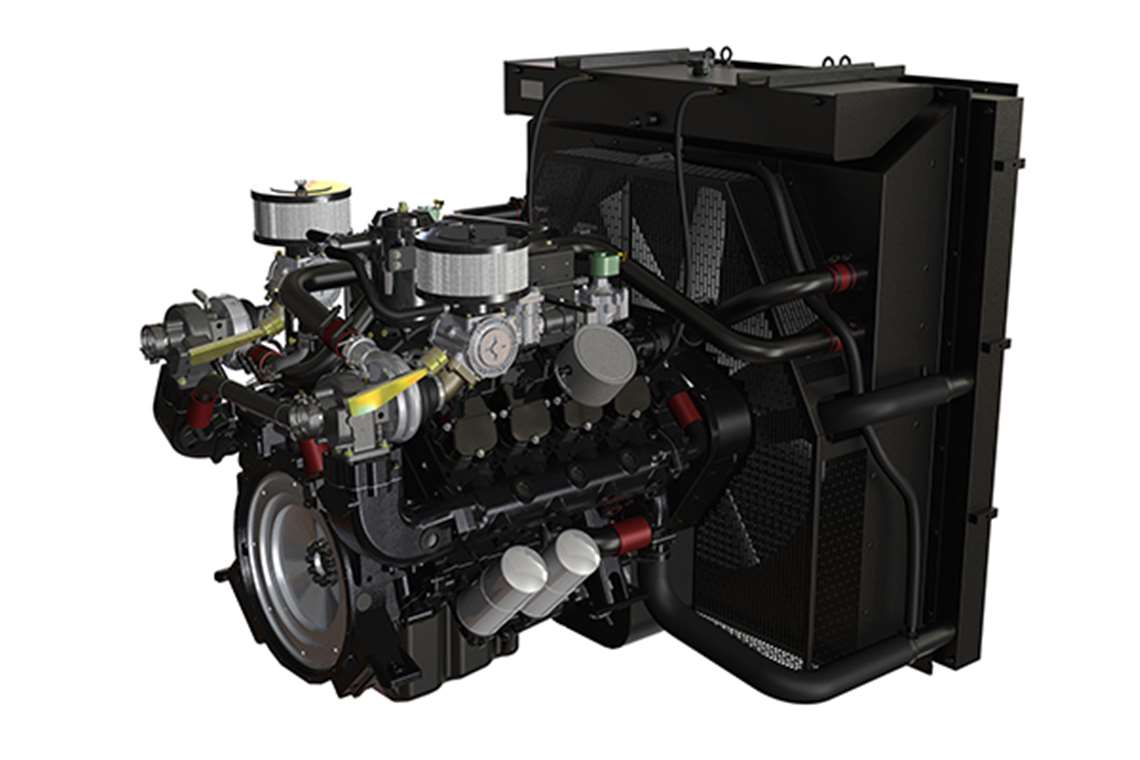

Company launches high-output versions of 14.6 and 21.9 L engines for standby applications

By Mike Brezonick

Aiming to deliver more compact and cost-effective solutions to the 350 kW and 500 kW power nodes, Power Solutions International (PSI), has developed new high-output versions of its 14.6 and 21.9 L gas engines.

The new natural gas high-output engines are EPA certified for emergency standby applications in the energy market, the company said. PSI said its engineering department made a number of improvements to each engine to boost their maximum power ratings, which have been validated through rigorous reliability and durability testing.

“One of PSI’s greatest assets is our advanced engineering and R&D capabilities,” said Mike Biltimier, vice president, Energy Division at PSI. “We took a deep look at the existing platform and advanced the components and bill of materials. We also leveraged our in-house testing capabilities to achieve the new ratings.”

Engine Details

The eight-cylinder, high-output 14.6 L engine can deliver a maximum electrical output of 350 kWe (400 kW/536 hp mechanical) at 1800 rpm, above the maximum power rating of 300 kWe (340 kW/455 hp mechanical) for the standard version of the same engine.

The 12-cylinder high-output 21.9 L engine has a maximum power rating of 500 kWe (570 kW/764 hp mechanical) at 1800 rpm, above its standard maximum power rating of 450 kwe (510 kW/683 hp mechanical).

The standard versions of the 14.6 and 21.9 L engines remain available to customers, PSI said. The engines target a range of market segments, including oil & gas, telecommunications, data centers, health care facilities, office and commercial sites and utility and water treatment facilities.

Both the 14.6 and 21.9 are 90° V configuration, water- and air-to-air intercooled and turbocharged engines based on Doosan engine blocks that are modified, gasified and manufactured by PSI at its Wood Dale, Ill., facilities. Each incorporates cast iron blocks, two-valve heads, replaceable wet cylinder liners, as well as crankshaft gear-driven oil systems with cartridge-type filters, belt-driven centrifugal water pumps, 24 V dc starters and alternators and self-tensioning serpentine fan belts. The engines also include three-way catalytic converter exhaust systems.

Telematics

Engine control is through an ECU control module, with coil-on-plug variable timing ignition and integrated knock sensing and control. CAN compatible with a J1939 interface, the engines come with one year of PSI’s MasterTrak telematics service.

PSI supplies generator set engines from 2.4 L to 53 L and from 25 kW to 1250 kW in the natural gas standby and prime market, as well as complete power generation systems.

This story first appeared in the August issue of Diesel Progress. To subscribe, click here.

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

CONNECT WITH THE TEAM