New Power Progress Yearbook highlights zero-carbon solutions

17 August 2022

New technology is often met by detractors who can rattle off dozens of reasons for why “It won’t work.” In many ways, they play an important role in the product development cycle because their prognosticating – negative as it is – can help point the way toward potential stumbling blocks for engineering and marketing.

Armed with a long list of suggestions for why “it’ll never work,” research and development teams can work to ensure trade show hecklers and anonymous social media trolls are proven wrong.

An annual project like this New Power Progress Yearbook — now in its third year — provides an opportunity to take stock in where the industry has come in a set amount of time.

From suppliers and OEMs who are partnering with mining companies to ensure a reliable source of raw material, to recycling end-of-life batteries, to reliable cold-weather transportation and everything in between, suppliers are working to find a way to ensure zero-carbon machines will get as much work done as their gasoline- and diesel-powered counterparts. Much progress has been made.

If there’s any consensus right now, it’s that there is likely no “one size fits all” power source in the future for the mobile on- and off-highway equipment world. A recent study conducted by Liebherr Group suggested a technology neutral approach is key, adding that battery electric should not be viewed as a universal solution, but as one important technology in the future drivetrain mix.

ALLISON TRANSMISSION

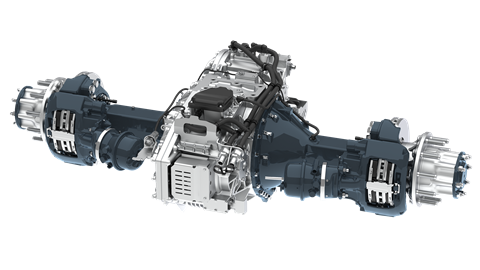

The eGen Power 100D electric axle from Allison Transmission.

The eGen Power 100D electric axle from Allison Transmission.

Indianapolis, Ind.

Web: allisontransmission.com/ev-solutions

PRODUCT LINE

Electric hybrid and fully electric vehicle (EV) propulsion solutions

COMPANY NEWS

In May, Allison Transmission announced a partnership with Xos Inc., a California-based manufacturer of battery-electric vehicles, to jointly develop Class 7 and 8 commercial EVs. It has delivered eGen Power e-Axle hardware for integration, validation and testing in vehicle platforms designed and built by Xos. Allison plans to deliver additional eGen Power 100S and 100D units throughout 2022.

In March, the company opened the 96000 sq. ft. Allison Transmission Innovation Center. Located on the campus of its headquarters in Indianapolis, the center is home to approximately 300 employees, consolidating engineering teams from multiple locations. The recently expanded Vehicle Electrification and Environmental Test Center is located on the same campus.

The same month, the company said Hino Trucks was testing and validating Allison’s next-generation eGen Power 100D fully electric axle in its XL series heavy-duty battery EVs as Hino progresses toward start of production.

The eGen Power electric axles are designed to fit between the wheels of trucks and buses, replacing a traditional drivetrain. It has fully integrated electric motors, a multi-speed gearbox, oil cooler and pump.

BAE SYSTEMS

BAE Systems HybriGen power and propulsion system for marine applications. (Illustration: BAE Systems)

BAE Systems HybriGen power and propulsion system for marine applications. (Illustration: BAE Systems)

Endicott, N.Y.

Web: gettozero.com

PRODUCT LINE

Propulsion systems for battery-electric, hydrogen-fuel cell and electric-hybrid solutions

COMPANY NEWS

In June, the company announced that it was selected by the Toronto Transit Commission in Canada to provide more than 335 electric drive systems for a new fleet of zero-emission capable hybrid transit buses. The selection comes on the heels of a separate order to supply 165 of the electric drive systems to nearby Mississauga Transit.

Its Series ER system assists transit agencies as they transition to a full zero-emission operation. The company said it uses its next-generation components with advanced materials and a lightweight, compact design.

BAE Systems said it has more than 15000 power and propulsion systems in electrified commercial vehicles across the globe, which have logged 4 billion on-road miles.

Its Modular Accessory Power System (MAPS) and Modular Power Control System (MPCS) allow for scalable, customized solutions to provide power for a range of applications, from school buses to sanitation trucks.

In late 2021, the company launched its next-generation marine power and propulsion system. The HybriGen power and propulsion system is a flexible solution to help operators reach zero emissions, said the company, by improving electrical efficiency and vessel range, increasing propulsion power and simplifying installation.

MAPS and MPCS allow for a scalable solution to fit the power and propulsion requirements of a range of vessels, including tugboats and passenger ferries.

BENEVELLI ELECTRIC POWERTRAIN SOLUTIONS

(Canimex Inc., North American distributor)

Drummondville, QC, Canada

Product Line

Complete powertrains for EVs with output torque up to 2500 Nm, ac electric motors and synchronous interior permanent magnet motors (IPM) with output power from 300 W to 200 kW, liquid-cooled electric motors

Company News

The company recently launched a new Series WD220 wheel drive for applications such as agricultural vehicles and construction machinery. It has an integrated IPM electric motor that distributes power directly to the wheels. An electronic differential prevents wheel slipping.

The company said the solution is up to 50% more compact than a traditional driveline and simplifies the machine design, as the battery can be placed on a flat chassis. Servicing is simplified due to access on the outside of the chassis; the replacement of sensors can be carried out in a matter of minutes.

BOSCH REXROTH CORP.

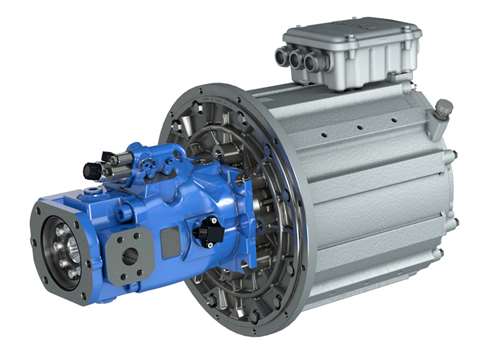

The eLION electric motor and hydraulic pump from Bosch Rexroth.

The eLION electric motor and hydraulic pump from Bosch Rexroth.

Charlotte, N.C.

Product Line

Electric motors, inverters, gear systems, control software

Company News

Bosch Rexroth is significantly expanding its electrification capabilities in the off-highway segment with the development of its eLION components for electrifying mobile working machines.

The 700 V eLION motor-generators cover a nominal power range from 20 to 200 kW (26.8 to 268 hp), with peak outputs up to 400 kW (536 hp), and deliver maximum torques of up to 2400 Nm (1764 lb.ft.). Available in four sizes with different lengths and winding configurations, more than 80 configurations are possible, which Bosch Rexroth said provides maximum design freedom for manufacturers when electrifying existing and new vehicle architectures.

The eLION range also includes inverters in various power classes with up to 300 A continuous current and high overload capacity. The inverters support dc bus voltages from 400 to 850 V. Gearboxes with high power density for hub and central drive configurations (eGFT and eGFZ) are also part of the eLION portfolio and allow compact drive units for a wide range of applications, the company said.

Bosch Rexroth’s BODAS software modules are available for the entire eLION platform, along with matching hydraulic components such as axial piston pumps, as well as electrical components such as DC/DC converters, power distribution units, onboard chargers and high-voltage cables.

More details on the eLION portfolio will be included in an upcoming issue of Diesel Progress.

BRIGGS & STRATTON

The Vanguard Swappable Battery Pack has been designed and tested for tough environments and is backed by a three-year commercial limited warranty. (Photo: Vanguard)

The Vanguard Swappable Battery Pack has been designed and tested for tough environments and is backed by a three-year commercial limited warranty. (Photo: Vanguard)

Vanguard

Milwaukee, Wis.

Product Line

Modular lithium-ion batteries

Company News

Vanguard said it is expanding access to practical electrification applications with the introduction of the Vanguard Si1.5 Swappable Battery Pack. It provides users with a versatile power solution that can be removed and replaced as needed to reduce downtime and bolster productivity. The company said it will be helpful for a variety of construction, agricultural, lawn and garden and industrial applications.

Like other Vanguard lithium-ion battery packs, the new pack can be used in tandem with other like packs to ensure larger power needs can be met. The pack’s battery management system is set up for network communication so users can monitor and control the battery product remotely as well as conduct fleet management

CATERPILLAR

Deerfield, Ill.

Web: www.cat.com

Product Line

Hydrid and electric drive systems, complete machines

Company News

Caterpillar Inc. announced a low-carbon-intensity fuel project with District Energy St. Paul (Minn.) to demonstrate a 2.0 MW combined heat and power (CHP) system fueled by various combinations of hydrogen and natural gas.

With preparations starting in the second quarter of this year and operations commencing in 2023, participants will develop and demonstrate a hydrogen-fueled power delivery and control system to evaluate its greenhouse gas (GHG) emissions profile, reliability, durability and barriers to adoption. To fully assess every aspect of the hydrogen solution under real-world operating conditions, power and heat from the demonstration project will feed into District Energy St. Paul’s distribution system.

In late 2021, Caterpillar Venture Capital, a wholly owned subsidiary of Caterpillar Inc., invested in BrightVolt Inc., a U.S.-based company engaged in the development and manufacturing of solid-state lithium-Ion batteries.

Caterpillar offers battery-powered equipment for the mining, construction, energy and transportation industries and announced seven sustainability goals to achieve by 2030, including that 100% of Caterpillar’s new products through 2030 will be more sustainable than the previous generation.

COULOMB SOLUTIONS INC.

Livermore, Calif.

Product Line

North American distributor and integration resource for CATL’s LFP (lithium-iron phosphate) battery solutions for commercial applications; medium- and high-voltage electric accessory components integrated into CATL battery systems such as battery thermal management systems, air compressors, power steering pumps, water heaters, A/C compressors, dc-dc converters, onboard chargers and configurable PDUs.

Company News

CSI said it will soon be manufacturing batteries and some of its most popular components in the United States to better serve its OEM customers and other partners, helping them comply with United States-Mexico-Canada Agreement (USMCA) and Buy American requirements where applicable.

CUMMINS

Products and technology from Cummins’ New Power business are used in the Letenda Electrip transit bus designed to operate in the cold winters using electric propulsion. (Photo: Cummins)

Products and technology from Cummins’ New Power business are used in the Letenda Electrip transit bus designed to operate in the cold winters using electric propulsion. (Photo: Cummins)

Columbus, Ind.

Web: www.cummins.com

Product Line

Electrified power technologies and products, including battery-electric powertrain; PEM and alkaline hydrogen generators for industrial processes, fueling stations and MW scale energy storage; hydrogen fuel cells

Company News

Cummins said its fuel-agnostic engines will be suitable for a wide range of on- and off-highway applications and will use engine blocks and core components that share common architectures, optimized for different low-carbon fuel types.

This new design approach will be applied across the company’s B, L and X Series engine portfolios, which will be available for clean diesel, natural gas and hydrogen. The company said the approach will allow customers to select the right powertrain for their application and duty cycle with the lowest CO2 impact.

In January 2022, Cummins acquired a 50% equity interest in Momentum Fuel Technologies from Rush Enterprises. The JV will seek to enhance production of near-zero emissions natural gas powertrains by manufacturing Cummins-branded natural gas fuel delivery systems for the North American commercial vehicle market in North America.

Cummins has also acquired Meritor, which it said will create a platform to deliver optimized powertrains as well as to advance electrification efforts.

Letenda, a bus OEM founded in 2016, chose a complete electrified powertrain solution from Cummins’ New Power business, including powertrain controls, three battery packs providing 222 kWh capacity, propulsion motor, power electronics, charging controls and connectivity systems.

The new bus was unveiled in February. The Electrip transit bus was designed to operate in the country’s winter conditions using electric propulsion. At 30 ft. long, the flat foot bus can accommodate up to 45 people.

DANA INC.

Dana will develop the e-powertrain for Ox trucks. (Photo: Dana)

Dana will develop the e-powertrain for Ox trucks. (Photo: Dana)

Maumee, Ohio

Web: www.dana.com/e-mobility; www.danatm4.com

Product Line

Vehicle integration and engineering, hybrid-electric architectures, complete e-powertrain systems, complete e-drive systems, e-axles, e-hub drives, e-gearboxes, e-transmissions, on-engine generators, motor/inverter systems, electric motors, inverters, e-motion systems for work circuits, control systems, thermal management solutions including battery cooling plates and electronics cooling

Company News

In June, Dana said its operation in Birmingham, U.K., was awarded a $2.7 million grant to develop an e-powertrain for Ox Delivers, a utility vehicle designed to be shipped as a flat pack and assembled in the destination country. The truck is powered by the Dana Spicer Electrified eS4500i e-drive unit, which combines an electric motor, inverter, gearbox and software in a complete e-propulsion system.

The grant was awarded by the Advanced Propulsion Centre, a non-profit organization that facilitates U.K. government funding to research and development projects supporting the delivery of net-zero emission vehicles.

Dana received Leadership in Energy and Environmental Design (LEED) certification for its Sustainable Mobility Center in Ohio, its engineering center of excellence for e-propulsion products. The company said the center also offers a dynamic customer experience, showcasing the company’s electrified mobility technologies.

In November 2021, the Dana TM4 joint venture said it would establish a new factory in Åmål, Sweden, that will initially produce electric motors. The operation is expected to add to Dana’s portfolio of global electrodynamic facilities and will be the company’s largest in Europe. The facility is expected to open in late 2022.

With more than half of its three-year new business backlog coming from e-propulsion products, the company said it is increasing its capacity to deliver electric components and systems in the region.

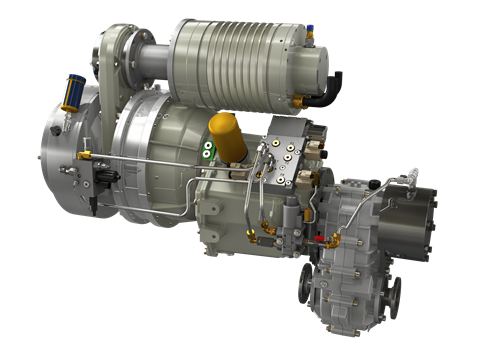

DANFOSS POWER SOLUTIONS’ EDITRON DIVISION

Danfoss Power Solutions’ Editron division will supply the electric propulsion system for a new hybrid ferry from Baltic Workboats. (Photo: Danfoss Power Solutions)

Danfoss Power Solutions’ Editron division will supply the electric propulsion system for a new hybrid ferry from Baltic Workboats. (Photo: Danfoss Power Solutions)

Longmont, Colo.

Web: https://www.danfoss.com/en/about-danfoss/our-businesses/power-solutions/danfoss-editron/

Product Line

Motors with a power capability of between 30 to 6000 kW, converters (inverters and dc-to-dc converters), traction systems (ranging from medium- and heavy-duty vehicles to transit buses)

Company News

Danfoss Power Solutions’ Editron division, now operating under a new name, said it will partner with Baltic Workboats to supply the electric propulsion system for the Estonian shipyard’s new hybrid passenger ferry. The hybrid ferry is designed to transport up to 50 passengers and 25 bicycles at a time. The vessel will primarily operate in fully electric mode only, which will help the Belgium government achieve its target of cutting transportation emissions by 27% before 2030 compared to 2005 levels. The Ferry 19 Electric is expected to be delivered in 2023.

On land, the company said it has provided the drivetrain for a new fully electric Doosan 16-ton wheeled excavator and 30-ton crawler excavator. Electrauvision, a division of Danfoss distributor Hydrauvison, supplied the components to Electric Construction Equipment, which has a license agreement to modify the equipment for Europe. The e-powertrain is equipped with a permanent magnet motor, controlled by a Danfoss controller and a display that uses Danfoss Plus+1 software platform. Both models have an exchange battery swapping system that can be charged at another location or by the machine. The first electric machines were delivered at the end of 2021 in the Netherlands and Norway.

In February, the company started mass production of its EM-PMI240-T180 motor at its Nanjing, China, factory. The motor has a power range of 49 kW to 122 kW, a nominal range speed of 2200 rpm to 8800 rpm and a maximum speed of up to 9200 rpm.

DELTA-Q TECHNOLOGIES

Burnaby, B.C., Canada

Web: https://delta-q.com/

Product Line

Battery charging solutions

Company News

Delta-Q Technologies shipped its four millionth battery charger in May. With each charger representing the potential to save 1 metric ton of emissions, the company said the milestone equates to 4 million metric tons of carbon emissions saved since the company’s founding, further cementing its imprint on global electrification and sustainability.

In April, the company received a $300000 grant from The CleanBC Go Electric Advanced Research and Commercialization (ARC) Program, part of the group’s “Roadmap to 2030.” Delta-Q said the funding will aid in the development of a family of high-power and high-voltage onboard battery chargers for commercial and industrial EVs.

DEUTZ CORP.

Norcross, Ga.

Product Line

Hybrid and all-electric drive systems for mobile off-highway equipment

Company News

Late last year, the company launched the TCG 7.8 H2, its first hydrogen engine. The six-cylinder TCG 7.8 H2 is based on an existing engine design.

The company said the engine meets the eligibility criteria set by the European Union for zero CO2 emission engines and that it is in addition to the company’s portfolio of low-emission and zero-emission drive systems.

RheinEnergie AG, a Cologne, Germany-based regional energy supplier, began trialing a power generation system incorporating the Deutz hydrogen engine in June.

The Deutz TCG 7.8 H2 hydrogen engine and a generator will deliver electric power of up to 170 kVA during the initial six-month test phase. The electricity will be fed directly into Cologne’s grid.

DRIVE SYSTEM DESIGN

Drive System Design’s Electrified Powertrain Optimization Process (ePOP) is a software-based tool to help EV providers select propulsion systems. (Photo: DSD)

Drive System Design’s Electrified Powertrain Optimization Process (ePOP) is a software-based tool to help EV providers select propulsion systems. (Photo: DSD)

Farmington Hills, Mich.

Product Line

Engineering services to support rapid engineering and development of electrified propulsion systems, including systems integration, simulation lead design, efficiency enhancement and development testing of propulsion systems

Company News

Drive System Design developed a thermal simulation and design toolchain – using Simulink Coder as the framework – that it said enables the rapid and accurate design of thermal systems. Its toolchain examines what is incorporated into heavy-duty EVs between the battery and the wheels and determines whether a passive cooling approach will work or if a more active approach (e.g., pumps, heat exchangers, etc.) is necessary for proper temperature management.

The outputs of the toolchain can tell customers the most effective thermal management solution, size for a heat exchanger, pump specifics and more. Additionally, it can model at a detailed level where heat is generated, how it is transferred and where it sinks to so customers can make better choices about how to design their systems.

The company said it has also made enhancements to its proprietary Electrified Powertrain Optimization Process (ePOP), a software-based tool to help electrified mobility providers identify the propulsion systems that best fit their specific needs. It said it is a comprehensive analysis tool that can quickly review tens to hundreds of thousands of powertrain combinations against cost, mass, range and efficiency, across multiple vehicle drive cycles, types and segments.

Through the analysis, the company said it can pinpoint a highly targeted subset of powertrain configurations that best align with customer requirements.

EATON

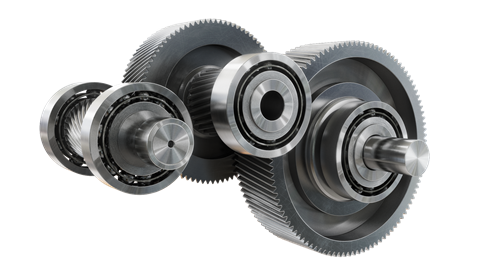

Eaton conducts total system analysis, using state of the art tools and in-house expertise, to design EV gearing solutions optimized for efficiency and reliability. (Photo: Eaton)

Eaton conducts total system analysis, using state of the art tools and in-house expertise, to design EV gearing solutions optimized for efficiency and reliability. (Photo: Eaton)

Galesburg, Mich.

Product Line

Power electronics (inverters, dc-dc converters, onboard chargers), power distribution and protection (power distribution units, fuses, Breaktor circuit protection) and power systems (EV transmissions, 48 V solutions)

Company News

Eaton’s eMobility business will supply its four-speed medium-duty electric vehicle ProDrive drivetrain for use in Proterra ZX5 electric transit buses.

Eaton said the transmission is a lightweight, countershaft gearbox with torque capacity up to 1200 Nm (885 lb.-ft.) and electric gearshift actuation that enables manufacturers to use smaller, more efficient motors. The transmission has fine-pitch helical gears that ensure smooth, low-noise operation and a shifting strategy designed to extend range and battery life. Road tests have shown a 20% to 30% efficiency improvement in energy consumption under normal driving conditions compared with a direct drive transmission, said the company.

Additionally, in February, Eaton’s Vehicle Group introduced its new ePowertrain business unit as an integrated powertrain solution for electrified vehicles that will focus on products from Eaton’s electrified vehicle transmission, reduction gearing and differential portfolios.

The company said combining the product lines into a new ePowertrain business unit creates synergy among Eaton’s powertrain and EV experts and allows the Vehicle Group to offer its global customers solutions for commercial and light-duty EVs.

Whether a large-scale project or a niche market application, Eaton said it is equipped to partner with customers on joint development programs or act as a single service provider of EV reduction gearing components or systems.

EDN

Balsamo, Italy

Web: www.edngroup.com

Product Line

Power electronics for electric and hybrid vehicles, onboard battery chargers, dc-dc converters and inverters

Company News

EDN develops and produces prime durability, scalable and sealed battery chargers, all with IP67 and IP6K9K protection rating, covering voltages up to 1000 V – easy to be integrated in buses, trucks and vans, underground vehicles and more. They are all built to resist hard environments and can be installed in any rugged application.

The latest development regarding onboard battery chargers for the American market is the BHP 19 for the heavy-duty, construction and agriculture markets. The company said it is able to work in charger mode and export power mode to perform vehicle-to-grid (V2G), vehicle-to-load (V2L) and vehicle-to-home (V2H) applications. In addition, when compared to other similar products, the company said volume and weight are lower by 30% and 25%, respectively, and the power density increased by 35%.

An 80% share of EDN belongs to MTA SpA.

ENERSYS

Designed for heavy-duty applications, the NexSys iON batteries from EnerSys have a modular construction. (Photo: EnerSys)

Designed for heavy-duty applications, the NexSys iON batteries from EnerSys have a modular construction. (Photo: EnerSys)

Reading, Pa.

Web: www.enersys.com; www.odysseybattery.com

Product Line

Thin plate pure lead (TPPL) and lithium-ion motive power batteries, Odyssey engine-cranking batteries, charging systems, power management tools

Company News

EnerSys said it is helping a big-box home improvement retailer reduce CO2 emissions and water consumption by switching its lift truck fleet power from flooded lead acid batteries to NexSys Pure Thin Plate Pure Lead (TPPL) battery technology. The change-over was part of the retailer’s ambitious goals – including a 40% reduction in its Scope 1 and Scope 2 emissions by 2030. Scope 1 emissions come directly from the retailer’s own facilities and vehicles, including its logistics network and Distribution Centers (DCs). Assisting EnerSys is Industrial Battery & Charger Inc., a Charlotte, N.C.-based battery dealer-distributor helping the retailer outfit its lift trucks with 2886 NexSys PURE TPPL batteries.

In March, the company showed its family of battery solutions at the Modex 2022 supply chain show, including its NexSys iON lithium-ion batteries and NexSys Pure TPPL batteries. Designed for heavy-duty applications, NexSys iON batteries have a modular construction and can be customized to precise power and fleet demands.

EnerSys obtained UL 2580 Listing of its NexSys iON batteries, which applies to batteries in EVs such as forklift trucks. UL 2580 Listing includes the assessment of several safety protocols such as simulated abuse conditions.

The batteries are also designed to meet Automotive/Rigorous Functional Safety Standard ISO 26262, which EnerSys said makes it the first battery manufacturer to bring this compliance standard to the material handling industry.

FLASH BATTERY SRL

Flash Battery lithium-ion battery packs

Flash Battery lithium-ion battery packs

Reggio Emilia, Italy

Product Line

Lithium-ion batteries for industrial sectors

Company News

The company’s product portfolio includes more than 500 different types of lithium batteries installed in over 15000 applications worldwide. The industrial machine segment is worth about 45% of the company’s turnover and the AGV/LGV (automatic guided vehicles/laser-guided vehicles) sector is worth around 40%, followed by EVs. Flash Battery said it is seeing more interest from the world of construction and agriculture.

Flash Battery said one of its main characteristics is high product customization. All batteries are tailor-made to the requirements of each application. The role of the company, it said, is to work alongside the manufacturer in the most difficult part of the process, i.e., choosing the best solution for each application. The company said its R&D department employs 35% of its total workforce.

The company said the development of third-generation cells enabled the company to significantly increase the energy density of its battery packs: from 134 Wh/L to 207 Wh/L in three years. This higher energy density also means a smaller battery pack volume, it said, which does not alter the high safety levels that are already guaranteed for each lithium battery.

The company’s proprietary battery management system (BMS) is the Flash Balancing System, which it said can act actively and passively with a balancing power that by far exceeds conventional BMS systems (20 A), not only at the end of the charging cycle but also in active mode during charging and discharging. The company said this brings several advantages, such as fast balancing times (under 30 minutes) and maximum run time for its batteries.

Flash Battery has chosen bauma 2022 in Germany to launch its new proprietary software Flash Data Center 4.0, a data control system that uses artificial intelligence. The Flash Data Center 4.0 cloud is integrated in a virtual environment with “Containerized Architecture,” which the company said ensures that all its systems are interconnected with support from machine learning technologies.

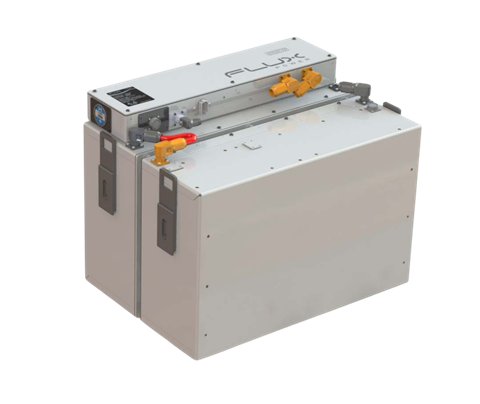

Flux Power L36-630 lithium-ion battery pack.

Flux Power L36-630 lithium-ion battery pack.

FLUX POWER

Vista, Calif.

Web: www.fluxpower.com

Product Line

Lithium-ion energy storage electrification solutions

Company News

Flux Power offers a full line of lithium-ion battery products from 24 V to 80 V, from 105 Ah to 840 Ah. It has also developed specialized high-voltage battery packs for use in electric equipment. Most of its battery packs are UL Listed.

The company is in the middle of a redesign phase for many of the products in its portfolio, and it showed off the early versions at Modex 2022 in March of this year. New products will continue to be launched throughout the second half of 2022:

Flux Power unveiled its C48 lithium-ion battery pack for Automated Guided Vehicles (AGV) and Autonomous Mobile Robots (AMR), as well as a new high-capacity S24 (210 Ah) battery pack for walkie pallet jacks at Modex 2022.

The company also unveiled its new L36 lithium-ion battery pack for three-wheel forklifts. “The new L36 lithium-ion battery pack will help companies solve a variety of existing performance challenges within their operations,” said Tod Kilgore, Flux Power vice president of sales.

FPT INDUSTRIAL

North America

New Holland, Pa.

Product Line

Hybrid power solutions, alternative fuel engines

Company News

FPT Industrial supplied F28 natural gas engines for two New Holland TK Methane Power crawler vineyard tractors that are powered by biomethane and utilized at a winery in Italy. The two tractors are part of a project with the wine producer to produce the first 100% sustainable wine.

The company is testing dimethyl ether (DME) as an alternative fuel. The research involves testing the fuel with an FPT Industrial 11 L heavy-duty diesel engine and is part of a project funded by SFOE (Swiss federal office for energy). The first experimental data is showing promising results in terms of CO2 reduction, FPT said, along with very low NOx and particle emissions and similar engine efficiency to a diesel.

FPT Industrial’s F28 Hybrid is a diesel engine paired with an e-flywheel, resulting in what it called an efficient, compact and sustainable solution for off-road applications. The 2.8-liter hybrid engine was developed to offer the ideal performance for compact machinery, said the company, offering enhanced productivity and improved efficiency.

The Hatz fiPMG system can provide diesel and battery performance in one machine. (Photo: Hatz)

The Hatz fiPMG system can provide diesel and battery performance in one machine. (Photo: Hatz)

HATZ DIESEL OF NORTH AMERICA

Waukesha, Wis.

Product Line

Integrated charging systems for hybrid applications, batteries

Company News

Designed for hybrid applications, the Hatz flywheel-integrated Permanent Magnet Generator (fiPMG) is based on a clean, air-cooled diesel engine and an integrated charging system. The company said integrating the generator into the face of the flywheel provides a smaller, lighter footprint than conventional diesel generators. The engines operate at a fully variable speed with an inverter, allowing for greater electrical output with a smaller displacement engine.

When used to charge lithium-Ion batteries, the fiPMG arrangement can provide diesel and battery performance in one machine. The greater energy density of diesel fuel can help extend the range of the machine and reduce the size and number of lithium-Ion batteries required for the task, Hatz said.

Based on its fiPMG generator design, Hatz showed a complete hybrid system concept incorporating the Vanguard lithium-ion battery pack on its stand during the 2022 World of Concrete trade show in Las Vegas. Vanguard had a similar display in its own booth.

Honda eGX electrified power unit

Honda eGX electrified power unit

HONDA

Alpharetta, Ga.

Web: powerequipment.honda.com; engines.honda.com

Product Line

Electrified power units

Company News

Honda Power Sports & Products, a business unit of American Honda Motor Co., Inc., designed its Honda eGX motor for OEMs that want battery-powered options. It is powered by a lithium-ion battery.

The Honda eGX is aligned with Honda Vision for 2030, which the company said, “encompasses creating and ensuring the joys of helping people make their lives better,” and represents the company’s R&D strategy to balance technological innovation, performance and environmental sustainability in Honda products and operations.

When developing new products, Honda Power Sports & Products said it can draw upon the R&D and technological investments from other parts of the company. For example, much of the insulation and coiling technology from Honda generators is built into the Honda eGX.

HYUNDAI DOOSAN INFRACORE

Seoul, South Korea

Web: www.hyundai-di.com

Company News

In September 2021, Hyundai Doosan Infracore changed its name as a subsidiary of Hyundai Heavy Industries Group’s construction machinery business. The company is currently affiliated with Hyundai Genuine, an intermediate holding company in the construction machinery sector of Hyundai Heavy Industries Group.

The company is developing 11 L hydrogen engines, with first firing scheduled in early 2023. The engines are also planned to be installed in vehicles such as trucks and buses by the end of 2023 and it is planned to expand to industrial applications in the future.

Hyundai Doosan Infracore said it plans to introduce a new e-powerpack in October, and that it will be a low-cost, high-efficiency battery pack system.

Since 2014, Kreisel has been focused on the development of immersion-cooled electric battery modules and packs for high-performance and off-highway applications. (Photo: John Deere Power Systems)

Since 2014, Kreisel has been focused on the development of immersion-cooled electric battery modules and packs for high-performance and off-highway applications. (Photo: John Deere Power Systems)

JOHN DEERE POWER SYSTEMS

Waterloo, Iowa

Web: www.deere.com/en/engines-and-drivetrain/vehicle-electrification/

Product Line

Hybrid, drivetrain and electronic solutions

Company News

In early 2022, Deere & Company acquired majority ownership in Kreisel Electric Inc., a battery technology provider based in Austria. Kreisel develops high-density, high-durability electric battery modules and packs. Additionally, Kreisel has developed a charging infrastructure platform that utilizes this patented battery technology.

The company said the investment provides it with optimal integration to efficiently design vehicles and powertrains around immersion-cooled, high-density battery technology.

In late 2021, Deere made an equity investment in ClearFlame Engine Technologies, a startup dedicated to the development of clean engine technology. ClearFlame’s solution enables low carbon fuels like ethanol to be easily integrated into compression ignition engines, offering a more sustainable solution without compromising engine performance.

LIEBHERR COMPONENTS

Liebherr used a 13.5 L D966 diesel engine to test Tula’s diesel Dynamic Skip Fire (dDSF) software. (Photo: Liebherr)

Liebherr used a 13.5 L D966 diesel engine to test Tula’s diesel Dynamic Skip Fire (dDSF) software. (Photo: Liebherr)

Nussbaumen, Switzerland

Web: www.liebherr.com

Product Line

Components for combustion engines, including fuel injection systems and controls

Company News

Liebherr-Components AG and U.S.-based Tula Technology carried out research on reducing GHG and nitrogen oxides (NOX) produced by heavy-duty equipment.

Based on simulations, Tula’s diesel Dynamic Skip Fire (dDSF) software allows the reduction of NOX tailpipe emissions by 41% and CO2 by 9.5%. For this study, Liebherr Machines Bulle SA provided its 13.5 L D966 diesel engine that operates in a variety of applications, such as mobile or maritime cranes and wheel loaders.

Liebherr-Components said it will continue to design a “proof of concept” hardware for the integration of Tula’s dDSF software into its engine system.

The D966 will be used in further tests. In the next step, Liebherr will consider the integration of the dDSF software into other engines in its portfolio.

LOOP ENERGY INC.

Bus builder ARCC will become Loop Energy’s first Australian customer. (Photo: Loop Energy)

Bus builder ARCC will become Loop Energy’s first Australian customer. (Photo: Loop Energy)

Burnaby, B.C., Canada

Web: www.loopenergy.com

Product Line

Hydrogen fuel cell systems

Company News

Loop Energy said it will enter the Australian bus market as a supplier of fuel cell modules to Aluminium Revolutionary Chassis Company (ARCC), the developer and manufacturer of what has been called Australia’s first lightweight bolted aluminum city bus chassis. ARCC is Loop Energy’s first Australian customer and underlines the country’s growing interest in utilizing hydrogen-electric vehicles to achieve its emissions reduction targets.

Loop Energy’s T600 (60 kW) fuel cell module will be integrated into ARCC’s 12.5-meter Viking Hydrolight city bus model, which aims to be in service by 2023.

In 2019, Australia launched its National Hydrogen Strategy, underpinning its intent to become a major global player in hydrogen by 2030. The New South Wales and Queensland governments have committed to scaling the production of Green Hydrogen and launching over 10000 hydrogen-electric vehicles collectively.

“The electric bus market is quickly emerging as an important market segment for fuel cells. We are very proud that we have continued to grow our footprint in this sector in Europe, China, Asia and now in Australia,” said George Rubin, Loop Energy chief commercial officer. “We view the partnership with ARCC as a positive step to continuing our inroads into the electric bus market and supporting the development of next-generation bus platforms globally.”

Loop Energy and ARCC plan to unveil the bus at the Australia Bus & Coach Expo in October 2022. The partnership will also see the companies develop strategies to position Viking Hydrolight buses as a solution for transit operators worldwide.

In March, Slovakia’s Mobility & Innovation launched its H2Bus for the European market, an 8 m hydrogen-electric minibus with seating for 21 passengers. Power comes from a Loop Energy S300 Series 30 kW hydrogen fuel cell system and an electric motor.

MTA USA CORP.

MTA offers products for high-voltage heavy-duty applications. (Photo: MTA)

MTA offers products for high-voltage heavy-duty applications. (Photo: MTA)

Elk Grove Village, Ill.

Web: www.mta.it

Product Line

Fuses, fuse holders, power distribution units (PDU), battery junction boxes and connectors, for 48 V up to 850 V applications, dashboards, displays and electronic control units

Company News

The latest developments for high-voltage heavy-duty applications include a modular PDU with integrated passive cooling systems that is flexible and adaptable to several platforms. It is made of aluminum plates and an internal resin layer ensures Ingress Protection (IP) and electrical insulation.

The company also offers a series of PDUs with integrated electronic components that can manage the communication protocols for the electric recharge stations: an Aux PDU, a Front PDU and a Rear Junction box. All these components are equipped with a 12 V safety circuit and the rear junction box includes an additional safety circuit which interrupts the current flow when the box cover is opened.

The acquisition of an 80% share of EDN allows the company to also offer onboard battery chargers and power converters, thus providing OEMs with complete and state of the art power electronic solutions.

An electric final drive combining Omni Powertrain’s VE34 gearbox and M27 motor. (Photo: Omni Powertrain)

An electric final drive combining Omni Powertrain’s VE34 gearbox and M27 motor. (Photo: Omni Powertrain)

OMNI POWERTRAIN TECHNOLOGIES

Houston, Texas

Product Line

Axial flux electric motors, e-drive transmissions, hub drives and power electronics

Company News

Omni Powertrain said it focused on powertrain design, and through its affiliated brands, offers components and system solutions for all types of powertrains – mechanical, hydraulic or electrical.

The company said it has been working with major OEMs in the turf care industry to offer electrified solutions for propulsion and deck cutting head motors.

Scania USA

San Antonio, Texas

Scania’s electric machine is rated for 230 kW continuous; 280 kW peak at 1500 rpm. (Photo: Scania)

Scania’s electric machine is rated for 230 kW continuous; 280 kW peak at 1500 rpm. (Photo: Scania)

Web: www.scania.com

Product Line

Motive power including electric motors and machines

Company News

Scania said its in-house developed electric solutions draw on the company’s long experience, knowledge and technology from electrifying on-road vehicles, resulting in high system reliability and performance in a compact design. This also facilitates builder design, installation and maintenance.

Like all Scania power systems, the electric components are modular and scalable, and thereby suitable for several different applications. The company said all components work seamlessly together and are controlled with a common management system, while standard mechanical interfaces simplify integration with external components. With impeccable interaction between different components to achieve full system integration, electrifying vehicles, vessels or equipment has never been smoother, the company said.

Scania´s hybrid electric power systems allow for the engine and e-machine to be run together or as standalone power sources. The adapted speed range of the electric machine means that a reduction gear can be avoided, minimizing energy loss and facilitating equipment design and installation, said the company. Altogether, the system enables improved powertrain performance with exceptional torque and response directly from idling, lowered fuel consumption that reduces operational cost and emission, as well as minimized noise when and where needed, the company said.

The high-power density electric machine offers maximum torque and response directly from start. In combination with state of the art batteries and other adjacent components, it eliminates tailpipe emissions and all but removes powertrain noise, Scania said. In addition, the low maintenance requirements help reduce operational cost.

TORQEEDO INC.

Oranje Nassau, a 20 m, 55-passenger sightseeing boat and water taxi operating on Berlin, Germany’s urban waterways was put back in service after replacing its diesel engine with an all-electric propulsion system by Torqeedo. The Torqeedo Deep Blue 50i electric drive is powered by three Deep Blue batteries with 120 kWh capacity, which provide energy for an eight-hour day at operating speeds, recharging from shore power connections overnight. (Photo: Torqeedo)

Oranje Nassau, a 20 m, 55-passenger sightseeing boat and water taxi operating on Berlin, Germany’s urban waterways was put back in service after replacing its diesel engine with an all-electric propulsion system by Torqeedo. The Torqeedo Deep Blue 50i electric drive is powered by three Deep Blue batteries with 120 kWh capacity, which provide energy for an eight-hour day at operating speeds, recharging from shore power connections overnight. (Photo: Torqeedo)

Crystal Lake, Ill.

Web: www.torqeedo.com

Product Line

Electric and hybrid drives for recreational and commercial vessels

Company News

Part of the Deutz Group, Torqeedo offers a range of marine electric and hybrid propulsion systems from 0.5 to 100 kW for commercial applications and recreational use. The installed base is just under 200000 vessels, ranging from small kayaks and inflatables up to larger craft, such as water taxis, ferries, patrol boats and all types of work boats.

New products for 2022 include a full product line upgrade for the Cruise series electric motors, now available in 3 kW, 6 kW and 12 kW electric outboard and pod motors. New features include a new electrical design with enhanced thermal behavior, a more robust aluminum pylon, ultra-quiet and durable helical gears and improved tiller functionality. The 12.0 and 6.0 systems now ship with Torqlink, Torqeedo’s advanced communications system, which allows faster and more accurate data sharing.

Torqeedo also announced in April a collaboration with Proton Motor Fuel Cell GmbH to integrate hydrogen fuel cell charging into Torqeedo’s Deep Blue high-voltage marine drives. The project, which has received funding from the Bavarian federal government, will provide propulsion power ranges from 50 to 200 kW and fuel cell power of 30 to 120 kW and will have flexible options for hydrogen storage.

Torqeedo completed several major projects and deployments for customers around the globe in 2021 and 2022.

A major operator of tourist boats on the waterways of Berlin has refitted a 20 m vessel with a Torqeedo Deep Blue 50i electric propulsion system that includes three large lithium-ion batteries with a total of 120 kWh storage capacity, more than enough to power a full day of cruising. The operator is planning to convert two sister ships.

Circular Explorer, a unique custom-designed vessel for cleaning up plastics and other litter from the surface of the water, was launched this year and deployed to Manila Bay in the Philippines. It is powered by two 50 kW Deep Blue electric motors and 40 kW lithium batteries with 24 steerable solar panels.

A major milestone was achieved in 2022 when Mahi Two became the first solar-electric 100% autonomous vessel to cross the Atlantic Ocean. The uncrewed four-meter vessel left the coast of Spain in September and reached Martinique six months later. It was powered by a Torqeedo Cruise 2.0 pod drive and a pair of 24V Torqeedo batteries, which were 100% recharged by solar panels.

In the Americas, recent projects have included a fleet of electric picnic boats and an electric replica historic canal boat in Washington, DC., and a fleet of water taxis in Toronto.

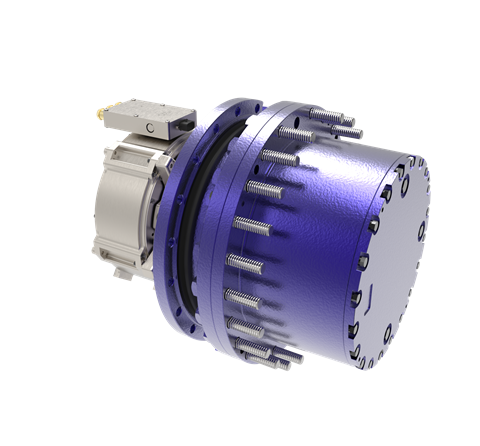

TRANSFLUID S.P.A.

Transfluid HTV700 hybrid system

Transfluid HTV700 hybrid system

Gallarate, Italy

Web: www.transfluid.eu

Product Line

Hybrid and full electric plug and play systems

Company News

Transfluid has designed and manufactured industrial transmissions and other driveline components since 1957, and for years these products have been the backbone of the company. Now, it has developed new hybrid and full electric plug and play systems for industrial and marine applications.

With these systems, the company said it can offer complete solutions as well as the technical support required by manufacturers to implement them.

Applications include earthmoving and agricultural machinery, forklift trucks, airport ground support equipment and railway vehicles.

Transfluid said the products are fully certified and have passed the most severe tests dictated by certification authorities.

VOLVO PENTA OF THE AMERICAS

TICO announced its collaboration with Volvo Penta in late March 2021, and by December the first of several emissions-free, fully electric terminal tractor prototypes were ready to undergo testing with TICO’s fleet partners. (Illustration: Volvo Penta)

TICO announced its collaboration with Volvo Penta in late March 2021, and by December the first of several emissions-free, fully electric terminal tractor prototypes were ready to undergo testing with TICO’s fleet partners. (Illustration: Volvo Penta)

Chesapeake, Va.

Web: www.volvopenta.com/en-us/

Product Line

Technology for renewable fuel, electric and hybrid industrial and marine applications

Company News

The Volvo Group has set clear goals to be a net-zero emissions company by 2050. Committing to the Science Based Targets initiative (SBTi) provides a pathway toward these targets in line with leading climate science.

As part of the Volvo Group, Volvo Penta said it is accelerating its sustainability development to reach zero emissions and leveraging the Volvo Group’s R&D. Volvo Penta is engaging with customers, supply chain partners, governments, societies and other stakeholders to pursue electrification and fuel cells.

Major electromobility milestones in 2022 included the first production deliveries of electric drivelines for Rosenbauer fire trucks and the delivery and integration of the first of a series of prototype fully electric terminal tractors for TICO, which will begin testing the prototypes with a variety of major fleet partners. Volvo Penta said it is in discussion with numerous other potential partners to continue the momentum in its sustainability development.

In the commercial marine segment, Volvo Penta and Danfoss Power Solutions’ Editron division collaborated to supply and commission the world’s first two hybrid electric wind farm crew transfer vessels (CTV), which are now in service in the U.K. Also, an advanced hybrid solution was developed and installed on an Arctic sightseeing vessel, which recently completed sea trials. The company said the vessel represents a big step in its journey to electromobility at sea.

WEBASTO GROUP

Fenton, Mich.

Web: https://www.webasto-group.com/en

Product Line

Battery packs and components, charging systems, thermal management solutions

Company News

During Webasto Group’s 2022 press conference, Dr. Holger Engelmann, chairman of the Management Board of Germany-based Webasto SE, said the company significantly increased its spending in research and development and investments in 2021 compared to the previous year. R&D expenditures totaled 315 million euros (up 17.6%) and were, in large part, spent for the preparation of project launches within roof and battery systems in Europe and Asia, and charging solutions in the Americas region.

Webasto said is electromobility solutions business is developing positively, particularly in respect to battery systems. The company has produced batteries for commercial vehicles in Germany since 2019, followed by its entry into the Asian passenger car market in 2021. At the beginning of this year, the company received new passenger car orders from Germany and South Korea with a total volume of more than 1 billion euros. The order intake of Webasto in the e-mobility segment exceeded that of its core business of roof systems and fuel-operated heating and cooling solutions for the first time in the first three months of 2022.

“Webasto has successfully established itself in the electromobility market and has bright prospects,” said Engelmann. “It was the right decision to invest massively in this area. Our dual strategy is working. In a focused manner, we will continue moving forward on our transformation and growth course.”

Xerotech Hibernium battery packs

Xerotech Hibernium battery packs

XEROTECH

Galway, Ireland

Web: www.xerotech.com

Product Line

High-voltage battery systems with pre-integrated onboard chargers, dc-dc converters and thermal systems

Company News

Xerotech is a battery technology company that designs, engineers and produces battery packs for non-road mobile machinery. Typically with electrification, people think automotive. The company said it focuses on “everything else” – off-road vehicles like those used in construction, mining and agriculture.

The company’s configurable battery system solution, Hibernium, enables a large variety of battery packs from 20 kWh to 300 kWh in regular increments that do not require unique engineering or design and development, offering OEMs the perfect battery for their particular machine regardless of annual production volumes, the company said.

Hibernium is built on a modular platform, allowing for high flexibility. A customer can choose their preferred energy content, operating voltage range, physical dimension and even battery cell chemistry.

Xerotech is also bringing several automotive-grade technologies to the off-road industry. The batteries have an advanced thermal management system that enables extremely high charge and discharge rates along with a specially engineered fire-retardant structural foam, which increases ruggedness and prevents thermal runaway propagation of battery cells.

Xerotech and IMK, an engineering firm that focuses on complete vehicle design, engineering and prototype builds, announced a strategic partnership to help OEMs electrify their fleets. The partnership leverages the strengths of the two firms to create a compelling offering to OEMs facing mounting pressure to reduce emissions and adopt EVs. Xerotech’s Hibernium platform batteries complement IMK’s vehicle design, engineering and prototyping expertise and enable the new wave of low-volume electrification.

Xerotech’s second-generation Hibernium battery system offers increased energy and power density, while keeping the same configurability, performance and safety that made the first generation a huge success, the company said.

ZF NORTH AMERICA

Vernon Hills, Ill.

Product Line

Electric drive components and mobile off-highway equipment systems

Company News

Guided by the principle of zero emissions, ZF said it strives to help mobile equipment OEMs offer emission-free products. The company’s electric eTRAC driveline system uses a 48, 96 or 650 V electric motor.

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

CONNECT WITH THE TEAM