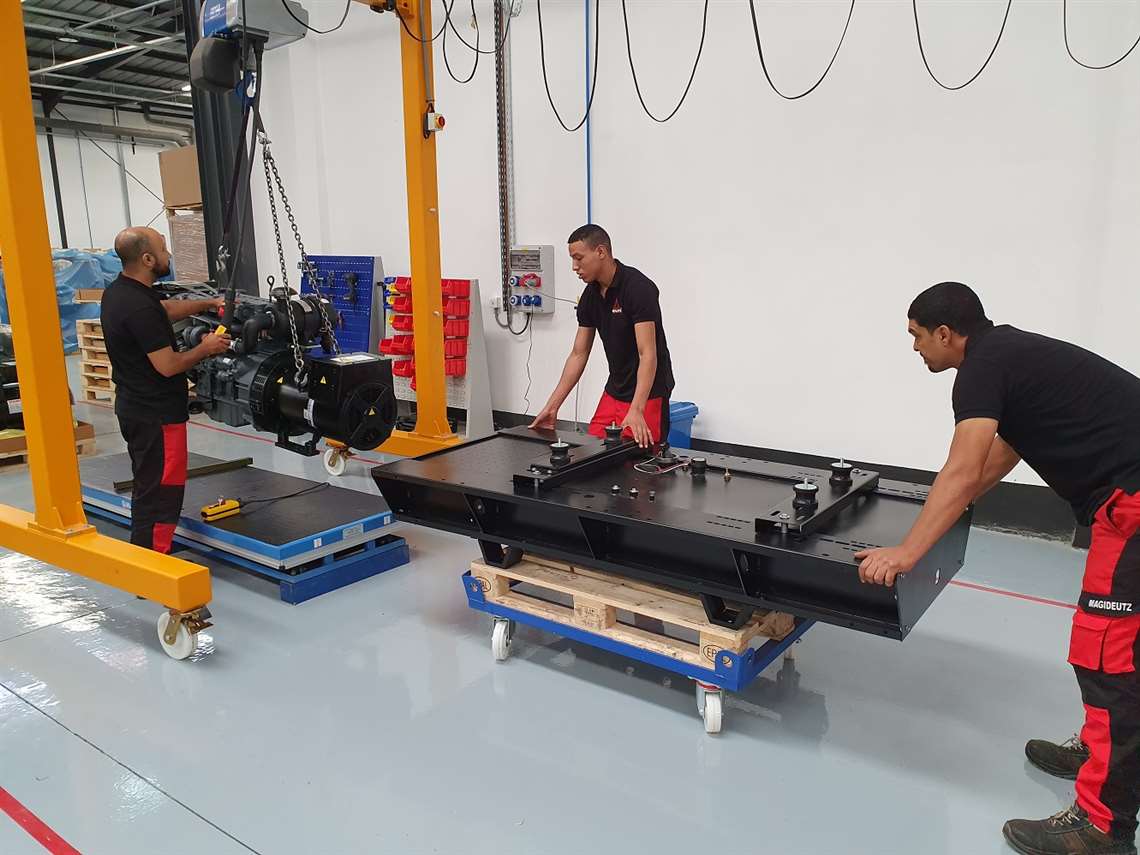

New Deutz Gen-Set Production In Morocco

16 October 2019

Deutz’s Moroccan subsidiary, MagiDeutz, is relocating its generator set manufacturing to a new production site in Sapino. This facility will now be the central production site for Deutz power generation equipment for the Northern African market.

The new site in Sapino is located in an industrial park close to the Casablanca airport. It covers an area of 3420 m2 to manufacture of Deutz gen-sets. Deutz said the manufacturing processes at the plant have been totally realigned and set new standards in terms of quality, productivity, and health and safety. The previous manufacturing site offered only limited scope for growth and modernization due to its central location in Casablanca.

Deutz offers both diesel and hybrid variants, either battery-driven or powered by a solar module. The concept is that if the engine generates more electricity than needed, any excess energy is stored in the battery. If required, this energy can then either boost the engine or even act as the sole power supply source, resulting in fuel savings of up to 65 per cent, Deutz said. If the diesel engine fails, the battery is also able to keep the genset operational for up to 24 hours.

The solar hybrid variant has a solar collector which, in particularly sunny parts of the world, is capable of providing most of the power needed by itself. The diesel engine starts up occasionally, providing additional support at power consumption peaks or on days when the sun does not shine. This allows efficient operation as regards fuel consumption and maintenance plus a long service life, Deutz said. Besides offering cost savings, hybrid solutions also represent a more environmentally sustainable source of energy with a lower carbon footprint.

Bernd Breves, general manager of MagiDeutz, said, “our new manufacturing facility will increase our production capacity considerably. We will now have a target capacity of 3000 units a year compared to 1000 units currently. This will allow us to supply our local customers with our tried and tested products even more quickly. What’s more, our local employees now have access to fully upgraded manufacturing equipment.”

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

CONNECT WITH THE TEAM