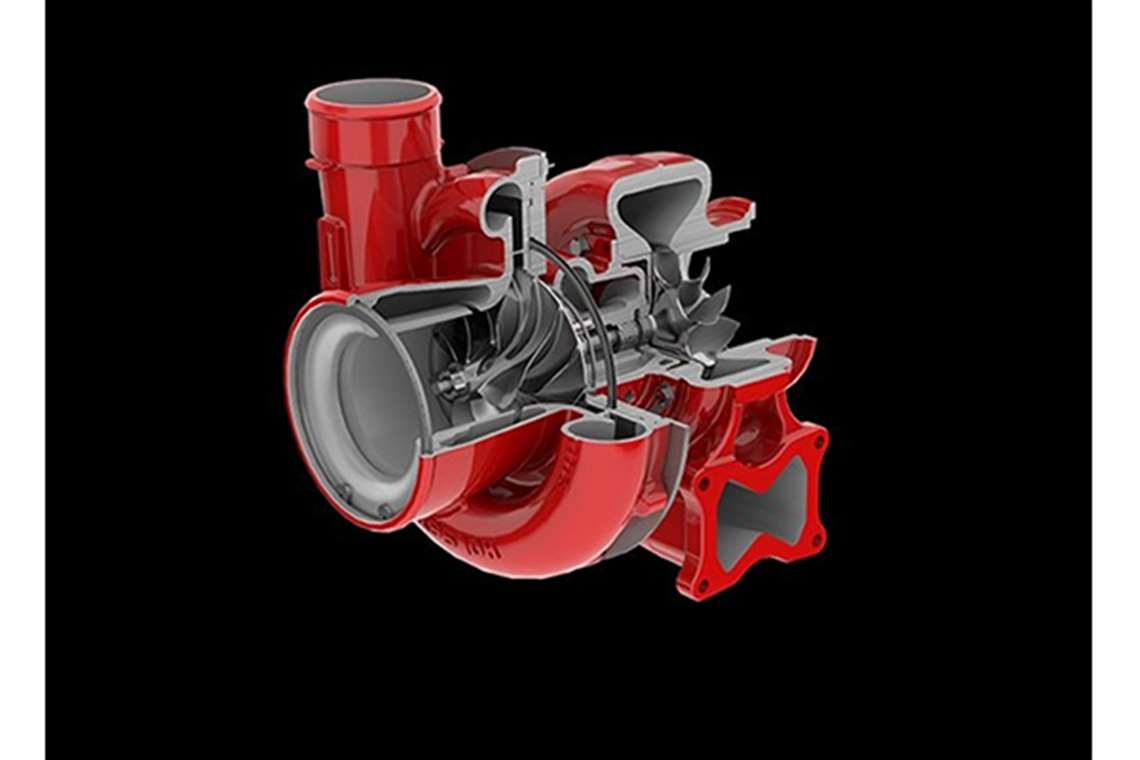

New Compressor Stage For Series 800 Holset Turbo

12 November 2020

Cummins Turbo Technologies (CTT) announced it has added new compressor stage technology to its Series 800 Holset turbocharger. The High-Pressure Ratio Compressor (HPRC) technology increases flow range capability by up to 25% and is optimized for pressure ratios of up to 6.5:1, CTT said.

The addition of the HPRC stage allows engines to be uprated by 20 to 40% while maintaining a single-stage architecture, the company said. CTT said it has also enabled additional altitude capability for many applications and improves overall efficiency, resulting in 5% to 7% BSFC improvements for existing applications during engine simulation work.

The new Series 800 Holset turbocharger is available with a thin walled stainless-steel compressor cover, which CTT said enables increased capability without adding to the unit’s weight or space claim. The Series 800 turbo also incorporates lead-free bearings, high temperature capable turbine housings and more robust joints and seals.

The upgraded Series 800 Turbocharger is available now and targets a wide range of off-highway engine applications including power generation, agricultural, mining, oil & gas, rail, construction and marine.

“We are excited to be offering new innovative technologies to increase the capability of the HE800 product line without needing additional space claim,” said Brett Fathauer, executive director – Engineering and Research at CTT. “We have been able to leverage our technical engineering expertise and advanced simulation analysis to provide critical air-handling features such as higher-pressure ratios and improved efficiencies while offering more product robustness.”

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

CONNECT WITH THE TEAM