Mahle Outlines Future Technology Path

16 October 2020

For much of its 100-year history, Germany’s Mahle Group has forged a reputation as a global supplier of key engine technologies for internal combustion engines used in everything from passenger cars to heavy-duty trucks, marine vessels and power generation systems.

Yet over the last several years, the company has begun to expand its focus into the world of electrification and e-mobility with electric drive systems and accessories.

Today at a press conference in Stuttgart, Germany, Mahle announced it will focus even more strongly on what it called “strategic future priorities,” and highlighted new coming new technologies related to batteries, mobile hydrogen storage tanks and hydrogen combustion engines.

“Viewed from an international perspective, there will not be one single powertrain of the future,” said Dr. Jörg Stratmann, chairman of the Mahle management board and CEO. “That’s why Mahle is continuing to follow its Dual Strategy – electrification, development of the fuel cell, and the use of hydrogen and alternative fuels in an intelligently electrified combustion engine.”

Hydrogen is key

Mahle said it sees the use of hydrogen as key when it comes to shaping carbon-neutral mobility, both as it relates to fuel cell technology and in combustion engines. At the press conference, Mahle’s head of Corporate Research and Advanced Engineering, Dr. Martin Berger, presented a current project involving a type IV hydrogen tank. The design consists of a plastic liner surrounded by an outer casing made of carbon fiber.

“This construction gives the pressure vessel a weight advantage over other designs,” Berger said. “We are currently developing a new production process for this tank. We want to optimize and speed up the carbon fiber winding process. This is where we can apply our expertise in the field of plastics and our broad experience with complex production technologies.

“On the one hand, we are aiming for a 10 to 15% increase in storage density. On the other hand, we want to reduce costs by 10% because we need fewer materials and can thus reduce machine expenses. Overall, this is an important step toward suitability for the mass market.”

Better battery cooling

To accelerate the market penetration of battery electric mobility, Berger gave an insight into another of Mahle’s new developments aimed at shortening the time involved in battery charging.

“The key challenge when it comes to fast charging is thermal management,” Berger said. “Because the charging power is limited by the maximum temperature of the battery and by the temperature differences in and between the cells.

“We have successfully shifted both limits considerably thanks to the use of a completely new solution: immersion cooling. In the process, we are doing something that may at first glance appear surprising — we are allowing a dielectric coolant to flow directly around the cells. Of course, this is not electrically conductive, and it lets us significantly decrease the maximum temperature and considerably improve the homogeneity of the temperature distribution.

“This opens up a whole new dimension to fast charging—as charging can take place in just a few minutes and thus makes batteries cheaper, lighter and much more durable. This is because the lower maximum temperature at high battery loads — when driving and fast charging — and the higher temperature homogeneity significantly improve the durability of the cells.

“Immersion cooling paves the way for a whole new generation of battery systems.”

The future of engines

The company also outlined what it called “combustion engine of the future,” a hybrid system that incorporates electrification with alternative fuels.

“Our Mahle Modular Hybrid Powertrain has proven that there is a great deal of potential in the combustion engine,” Berger said. “Over the entire operating map, we have the lowest emissions. This is made possible with products such as heat-resistant valves that allow high exhaust gas temperatures and consequently the rapid heating of the exhaust gas aftertreatment systems. Special pistons and rings ensure low oil consumption and low particulate emissions.

“In the transient range — or in dynamic driving situations — we support the combustion engine with an integrated electric motor. We can improve the existing fleet immediately by adding synthetic fuels or drive in a soot-free and CO2-neutral way by using “green” hydrogen and CO2 taken from the atmosphere as a fuel. This means we can burn fuel cleanly — and thus do more for the climate in some application areas than is currently possible with a battery electric vehicle.”

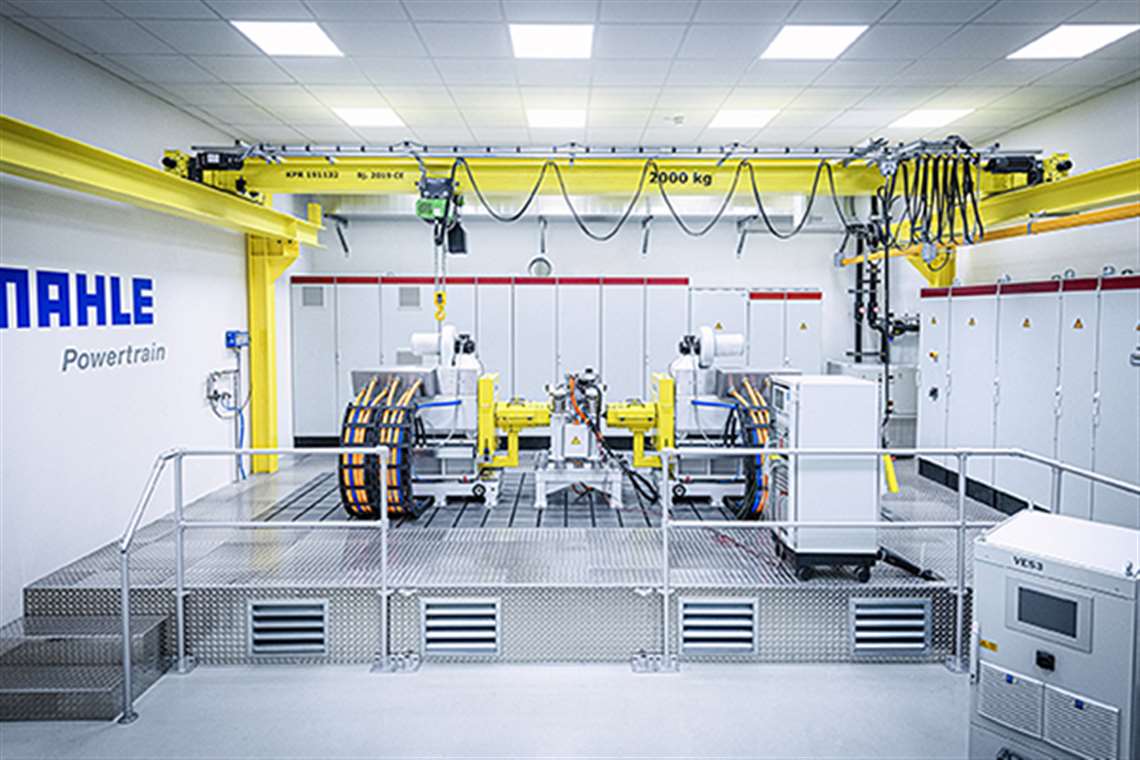

As part of its Dual Strategy, Mahle has expanded its global R&D infrastructure. This has included the establishment of a new competence center for mechatronics in Kornwestheim, Germany. In Fellbach, Germany, a new, ultramodern test bench for electric drives has been commissioned, which Mahle said is one of very few of its kind in Germany. Finally, an e-mobility development center in Suzhou, China, is scheduled for completion in December.

“With our Dual Strategy, we are continuing to optimize the combustion engine and simultaneously advancing all alternative drives,” Berger said. “Combustion engines that run on renewable fuels need to become part of the drive mix if we want to achieve the ambitious climate targets.”

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

CONNECT WITH THE TEAM