Kohler Power frames a solution for data centers

31 August 2021

Mike Brezonick discovers why data centers and mission-critical applications are the target for Kohler Power’s eFrame enclosures .

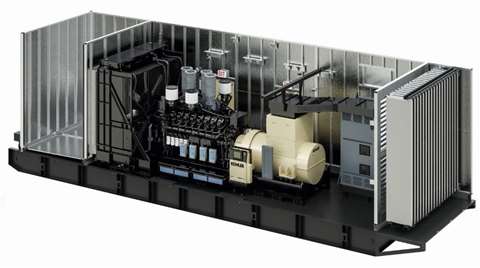

Kohler developed the new eFrame walk-in enclosures for its KD Series generator sets

Kohler developed the new eFrame walk-in enclosures for its KD Series generator sets

While make-or-buy decisions are a fact of life for most manufacturers, sometimes the best option is to do the important things yourself. That was Kohler Power’s conclusion which led to the development of its new eFrame generator set enclosures.

The eFrame enclosures, designed to house Kohler Power’s largest 2.0 through 4 MW KD Series gen-sets, have been engineered to meet the specific requirements of mission-critical applications – primarily data centers – while providing shorter lead times, earlier installation and better service as well as maintenance access.

Brad Meissner, product manager at Kohler Power, said, “When we developed the KD gen-sets we also launched enclosures up to 2500 kW. We were the first in the industry to offer factory packaged enclosures above 1 MW.”

The generator sets had to be shipped to third-party enclosure packagers as the KD range expanded to larger sizes, something that – while a relatively common practice in the power generation industry – Kohler became increasingly uncomfortable with.

Meissner explained, “Before now, everybody – including us – had to go to a third-party manufacturer for this size unit. There are a handful of them here in Wisconsin and many throughout the United States.

“Some of these are small manufacturers, which you could almost compare to a job shop. Some are bigger than others, but they all have the overarching issue of scale. The ability to handle product for many manufacturers, for many customers, can be an issue for them. Then you also encounter issues with product consistency and lead times, etc.”

Complicating the situation was also the fact that data center customers tend to be very exacting in terms of their enclosures.

Meissner added, “We found that the enclosures we were making for the KD gen-sets are a little bit different style than what something like a data center is going to require. Those enclosures were more like a skin-tight enclosure. Data centers tend to want a walk-in enclosure.

“Data center customers are in and around their gen-sets more frequently than the typical user. For the typical user it’s a safety net for their operation.

“Data centers consider it a more integral part of their operation because the power and uptime of their facilities are so critical. They are constantly working on testing, making sure that their generators are ready to go in case of an outage.

“That is where that walk-in clearance is going to come in. It is much easier for the technicians and their operations teams to be in and around the gen-sets.”

Kohler offers three different eFrame walk-in enclosures

The eFrame walk-in enclosures are available in three configurations – V12 (2000 kW to 2500 kW), V16 (2800 kW to 3250 kW) and V20 (3500 kW to 4000 kW). They incorporate an all-aluminum skin and frame construction, as well as a fade/scratch/corrosion-resistant powdered coat exterior. According to the company the enclosures meet or exceed 135-mph wind load ratings.

It is also UL2200 FTTP-certified for construction and IBC certified via analysis for site specific use. The sub-base tanks meet UL 142, ULC and state specific requirements.

Kohler eFrame’s modular design enables the enclosure to be separated into three sections

Kohler eFrame’s modular design enables the enclosure to be separated into three sections

A modular design allows the eFrame enclosures to be separated into three sections, each able to be independently removed in the field.

This is intended to enable users to service the engine and radiator without disconnecting any site connections that occur in the rear section. It also localizes the service work to avoid potential mishaps to other components while significantly reducing service costs and downtime, the company said.

Installation is straightforward, with the sub-base fuel tank set in place, the generator set mounted directly to the tank and then the enclosure placed atop the generator to making it essentially what Meissner describes as a “connect and go” system.

Meissner pointed out, “That was one of the biggest things we heard from data center customers. They want to be able to get a unit on order, get it onto their site and then deploy it as quickly as possible. And as we know, skilled labor is stressed within the United States, so the less stuff they have to do on the job site then the more they like it.”

Kohler can now provide a totally integrated package – with all components single-sourced from the Kohler factory including engineering, manufacturing, testing and enclosing – courtesy of the expansion at its manufacturing site in Mosel, Wisconsin, USA.

Kohler eFrame enclosures target where easy access to gen-set components is crucial

Kohler eFrame enclosures target where easy access to gen-set components is crucial

Meissner concluded, “It is the single source philosophy as a customer only has to deal with Kohler. There is no finger pointing, with third party packagers, if something occurs in the field because it can be dealt with in-house here.

“It allows us to control our own destiny as well. Especially now, where supply chains are getting very constrained. The more content you own, the more you can control it and the better service you provide your customers.”

Click here to learn more about Kohler Power

This story first appeared in the August issue of Diesel Progress. Click here for a free print or digital subscription.

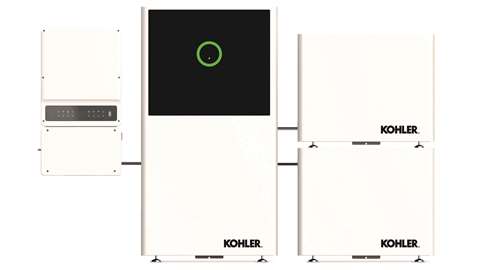

When Kohler Power unveiled its new Power Reserve line of energy storage batteries, it was the company’s next step into an increasingly important segment of the power generation industry.

Kohler’s Power Reserve lithium iron phosphate (LFP) batteries target home standby and light commercial standby power applications

Kohler’s Power Reserve lithium iron phosphate (LFP) batteries target home standby and light commercial standby power applications

Brian Melka, group president of Kohler Power, explained, “Power resilience is and has been a big part of our business. The Power Reserve is a great product extension for us and fits very well with our residential and light commercial business.

“We felt the timing was perfect for us to move into this technology. There are two big factors affecting the market at the same time.

The first is a significant increase in power instability as a lot more customers are recognizing they need power resilience, they need energy resilience but the grid is not reliable and their solar systems are not reliable.

“Many PV installations actually do not work if the grid goes down because they are grid tied. If you are producing excess energy in a grid tied solution, when the grid goes down, if you have no energy storage, you have nowhere to go with it.

“A customer can actually feed back through their meter and receive energy credits as a result of their PV in many installations. But when the grid goes down, they can no longer feed through the meter and they no longer have reliable power for their homes either.

International realisation of the importance of power resilience

“With the recent COVID-19 pandemic you also have people spending much more time in their homes. They are recognizing that power resilience is important, and that their power is not as reliable as they thought it was. Grid power actually goes out more than they were aware of and the solutions they have in place with PV are not as reliable as they thought they were.

“The other big change that is happening at the right time is that the cost per kWh has come down. The main component of these systems is the battery, and battery costs have continued to decline and are expected to continue declining over the coming years.

Brian Melka pointed out “We felt the timing was perfect for us to move into this technology”

Brian Melka pointed out “We felt the timing was perfect for us to move into this technology”

In development for nearly two years, the Kohler Power Reserve system consists of three main segments – batteries, inverters and an app used for control and monitoring. The batteries are lithium iron phosphate (LFP) chemistries available in 10, 15 and 20 kWh capacities, weighing from 346lb to 580 lb. The batteries offer outputs of 5.76 to 7.6 kW continuous (7.6 to 9 kW peak for 60 seconds) and carry a 10-year/3 MWh per kW battery warranty.

According to Kohler Power these batteries meet UL (1741 SA and 9540), CA Rule 21, HECO Rule 14, IEEE (1547 and 1547.1) and CSA 22 regulations.

Melka added, “The lithium battery solution we have chosen is safe for use in residential settings. Something we were very concerned about was making sure that not only that we had power density and long run time, but that we had a safe solution for those customers who want to mount these either on or inside their homes.

“With some manufacturers, you cannot buy their energy storage unless you buy their solar arrays and inverters. This leaves a large population of customers looking for a storage solution that may already have solar installed. Our solution is agnostic, you can use it with virtually anyone else’s system.”

Customers can access and manage their stored power through an app designed to provide insights into real-time power flow for the home or business, deliver a timeline of power information for the day and provide historical statistics for the system. It also allows users to choose the operation mode for their system – backup, self-supply or time-of-use– to personalize their battery’s storage and output.

Melka said, “One of the things we wanted to make sure we delivered was a very intuitive, easy-to-use app so that people can see their power needs. When we looked at this, we learned that early adopters wanted to see lots of bells and whistles and data.

“We are beyond the early adopter phase. What most people really expect is that it is going to work and that it is reliable because they want to trust it. They want some basic information and want it to be easy to use.

“One big thing that customers told us is that they want to make sure the company that builds and installs these units is going to stand behind them and be here in 10 or 20 years if it needs service or replacement. One of the reasons people have been asking us to do this is that Kohler Power has been in this business of distributed energy for 100 years – and we expect to be in it for another 100 years.”

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

CONNECT WITH THE TEAM