Isuzu Opens Prototype Center For Engines, Power Units

10 March 2020

On the opening day of ConExpo-Con/Agg, Isuzu Motors America announced that it has opened a new technical engineering facility in Wixom, Mich. Covering 8000 sq. ft., the new Engine and Power Unit Prototype Center was established to serve the company’s engine and power unit customers in power generation, ag, construction and other off-highway applications.

“The new facility allows us to design, source prototypes and perform all validation tests in one building,” said Cody Garcelon, director of Applications, Design and Sales Engineering for Isuzu Motors America. “This capacity helps us deliver validated engine system designs in a shorter timeframe, while delivering superior quality control and reducing customer-specific testing and engineering costs.”

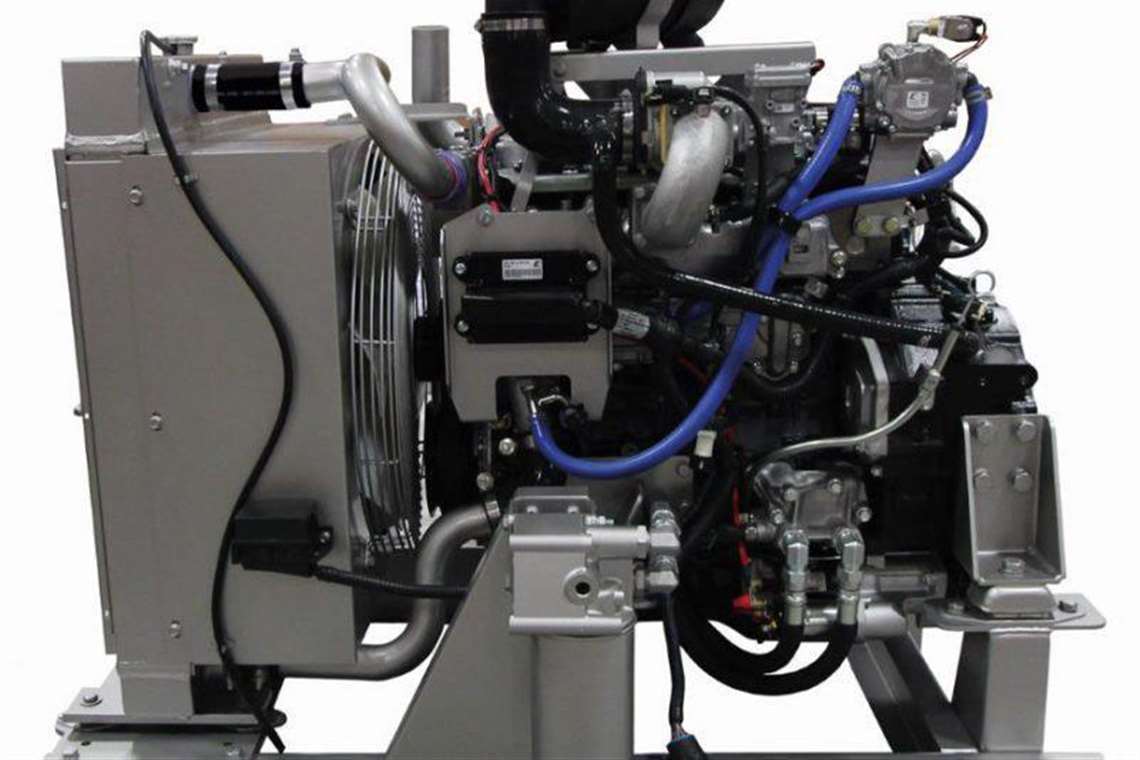

With design, applications and test engineers onsite, the new facility can design and prototype custom accessory kits, which adapt the base engine types to specific customer applications. These kits typically include exhaust systems, wiring harnesses, urea lines, cooling packages, air cleaner systems and engine/component mountings. Once the design and prototypes are complete, they are manufactured according to specification, the company said. Each customized kit is validated as a turnkey open power unit that that enables customers to meet EPA exhaust emissions regulations if used in the same complete configuration, Isuzu said.

The ability to perform highly complex work under the same roof as the design, sourcing and quality staff cuts the number of design cycles needed and improves customer time to market, the company said. “Being able to perform all the design, prototype and validation steps in the same location saves hundreds of hours of engineering, travel and personnel costs, as well as material costs,” Garcelon said.

A recent benefit of the new facility was that the company designed, validated, tested and released the new Isuzu 4HV1 dual-fuel engine and power unit, which can operate on natural gas or liquid propane.

The new facility will also be used for training distributors and customers. “We’ll be training our distributors in applications testing as well as providing training for engineers from original equipment manufacturers to help improve design and testing methods,” said Garcelon. The first onsite training programs are being planned for the third quarter of this year.

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

CONNECT WITH THE TEAM