How Mota is tailor-making cooling systems

02 December 2021

Mota is a cooling system partner for gen-sets, boats and more.

Effective cooling systems play a critical role in nearly every application, ranging from stationary gen-sets to marine vessels. However, many of these applications place significant restraints on the design the cooling system. Engineers must ensure engines get systems that are reliable and robust, even in an environment where space is limited.

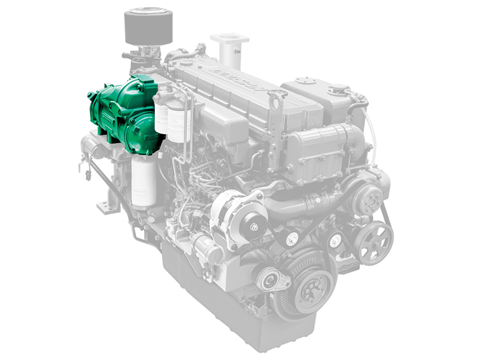

A Scania V8 marine engine with a complete Mota cooling system designed for the application.

A Scania V8 marine engine with a complete Mota cooling system designed for the application.

A key feature of the products and systems offered by Mota focus on providing cooling systems tailored to an application, with its engineers giving the marine and industrial industries a strong focus. Based in Aubagne, France, the company was established in 1958.

Mota services

“We have been providing complete cooling systems for marine OEMs for more than three decades, designing and supplying heat exchangers, oil coolers, intercoolers, fuel coolers and gearbox oil coolers,” said Camille Moreaux, project manager, Mota. “However, one of our main advantages is that we can supply heat exchangers and coolers with integrated functions.

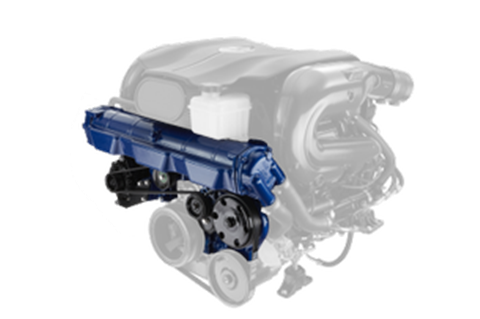

An application-specific Mota system as shown on a Doosan DX12 marine engine.

An application-specific Mota system as shown on a Doosan DX12 marine engine.

“For example, functions we integrate into the cooling system include the thermostat, the pressure valves and the expansion tank and it’s the same on the oil cooler - we can also integrate the oil filter, pressure relief valves and additional functions. When we integrate functions, we can reduce the number of parts on the engine. This also makes the installation process of the cooling system easier for our engine customers.”

The company uses heat exchangers with two O rings on either side to ensure fluids do not mix.

“Another advantage is our capacity to design and to help our customers to define and optimise the complete, bespoke, cooling system,” said Moreaux. “Customers, particularly in the marine industry, need very specific cooling systems but they face big constraints. They have high reliability expectations, low to medium volumes but they don’t want high costs and they have space constraints. We can work along with the design department at the engine company and design the complete cooling system to fit all in the best package.

An FPT N67 engine used for marine or fire pump applications with a Mota cooling system.

An FPT N67 engine used for marine or fire pump applications with a Mota cooling system.

Volvo Penta, Caterpillar and Yanmar

Moreaux said the company has worked with major engine makers including Volvo Penta, Caterpillar, Yanmar and Scania.

Previously, the company’s technology was confined to the engine manufacturers it works with, but Moreaux said it is now available across its standard range of coolers for everyone in a catalogue format. The company works with applications such as gen-sets, fire pumps and irrigation systems.

“We can now offer top quality and performance heat exchangers, intercoolers and even expansion tanks for these systems even with very low volumes and no investment required,” said Moreaux. “Mota is a one-stop-supplier for applications where quality and reliability requirements are of utmost importance.”

In the marine sector, for example, Mota mainly supplies engine and gearbox manufacturers for various commercial vessels such as tugboats, inland waterway vessels, pilot boats and pleasure craft mainly with engines up to a 32 L displacement.

Ilmor gasoline engine developed for the U.S. pleasure craft market equipped with a Mota cooling system.

Ilmor gasoline engine developed for the U.S. pleasure craft market equipped with a Mota cooling system.

Mota employs around 200 people, has its own aluminium foundry in Lenta, Italy, and opperates subsidiaries in Charleston, S.C., and Osaka, Japan.

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

CONNECT WITH THE TEAM