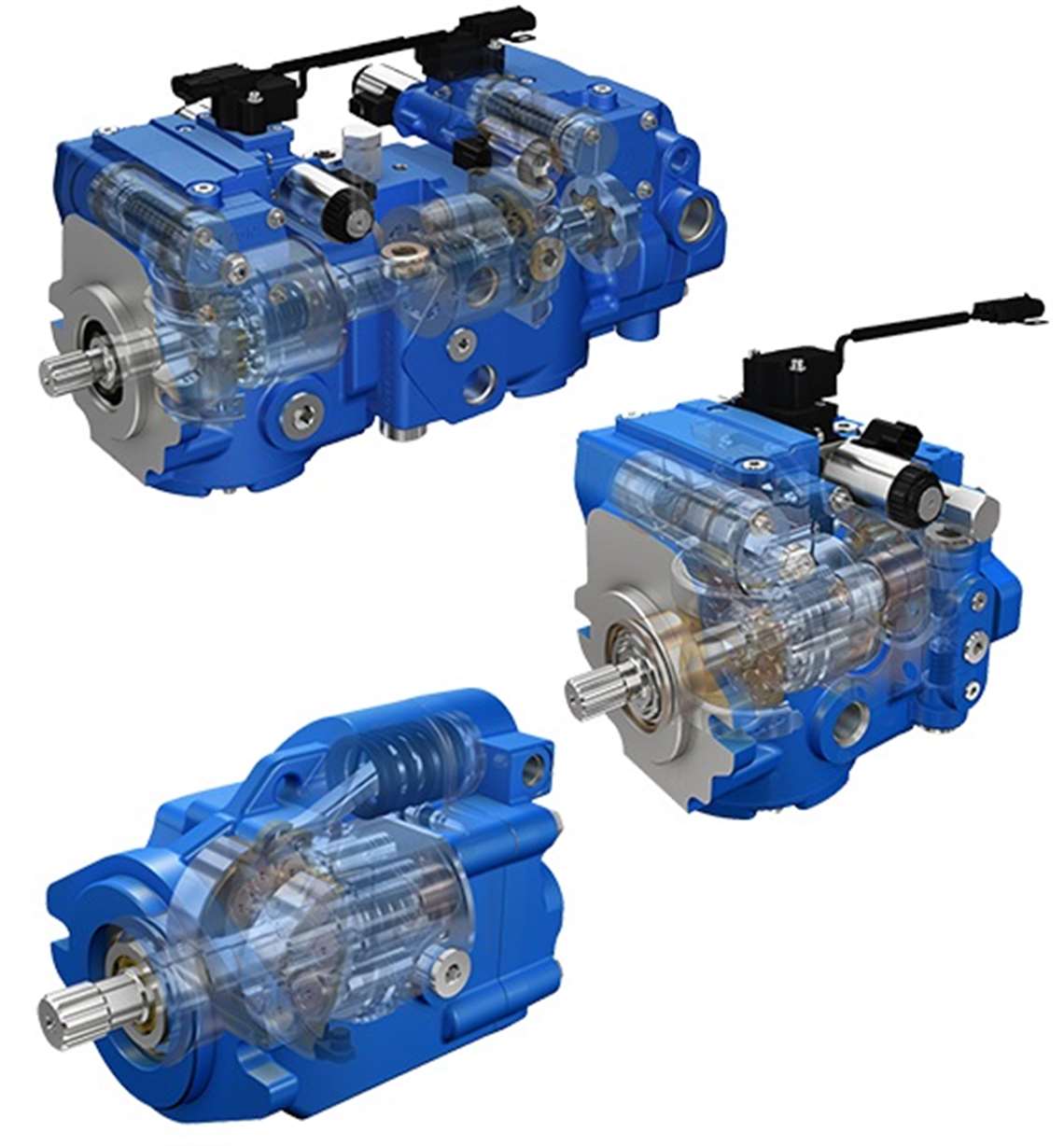

Eaton’s new X3 hydraulic pumps and motors

26 April 2021

Eaton has launched a new line of hydraulic pumps and motors designed for medium-duty propel applications in machinery such as aerial work platforms, boom lifts, ag sprayers, harvesters and windrowers, compactors, compact track loaders, skid-steer loaders, turf mowers and utility vehicles.

Eaton’s new X3 hydraulic pumps and motors target medium-duty propel applications in a broad range of construction, lift and material handling, ag and turf equipment.

Eaton’s new X3 hydraulic pumps and motors target medium-duty propel applications in a broad range of construction, lift and material handling, ag and turf equipment.

“Eaton’s X3 pump and motor portfolio offers a compact package for mobile applications where space is at a premium,” said Brent Schenk, global product manager, Medium-Pressure Closed-Circuit Piston products, Hydraulics, Eaton. “Providing more flexibility and customization in designing mobile machines, OEMs can combine improved control and accuracy as part of an advanced propel solution.”

Eaton’s X3 two-speed cartridge motor is available in displacements of 41 and 49 cc/rev at a maximum rated speed of 3500 rpm. Nominal working pressure is 5076 psi (350 bar) for the smaller unit and 4500 psi (310 bar) for the 49 cc motor. Maximum input torque is 394 lb. in. (0.65 Nm) for the 41 cc motor and 480 lb. in. (0.79 Nm) for the 49 cc unit.

The motor also has a built-in speed sensor port, making it easy to add a sensor to measure speed and direction, Eaton said. With a standard SAE B two-bolt mount, the motor will fit into virtually any existing machine design and can also be positioned as a drop-in replacement for several motor configurations, the company said.

The X3 pumps incorporate the same displacements as the X3 motors at maximum rated speeds of 3600 rpm. Working pressures for both single and tandem configurations are 5000 psi (345 bar) and maximum input torque is 2991 lb. in. (338 Nm). The pumps offer a 36% increase in side load capacity over previous generations of pumps, Eaton said, along with improved packaging that better protects the control solenoids against damage.

The X3 pumps and motors are Pro-FX Ready, able to accommodate a variety of control options, including a non-feedback electrohydraulic control, a hydraulic remote control and a manual servo control. When combined with an Eaton HFX programmable controller, the solution can actively sense and dynamically adjust parameters such as position and flow, the company said.

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

CONNECT WITH THE TEAM