Eaton’s circuit protection combination enhances EV protection

26 May 2022

Eaton’s eMobility business has introduced a battery disconnect unit (BDU) that can be combined with the company’s upgraded Breaktor circuit protection technology to provide circuit protection in electrified vehicles (EVs), plus reduce both complexity and cost.

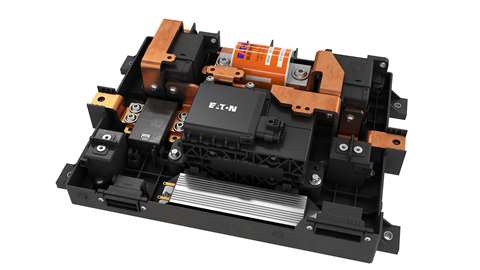

Eaton’s battery disconnect unit combined with Breaktor circuit protection technology provides circuit protection in electrified vehicles. (Photo: Business Wire)

Eaton’s battery disconnect unit combined with Breaktor circuit protection technology provides circuit protection in electrified vehicles. (Photo: Business Wire)

As EV power levels continue to rise, the need for more effective protection solutions has emerged. “As manufacturers continue to increase the power levels in EVs, it’s increasingly important to have capable and dependable protection solutions,” said Kevin Calzada, global product strategy manager, Eaton’s eMobility business. “Our BDU combined with our Breaktor circuit protection technology provides everything needed, in a compact and efficient package, to protect the vehicle and occupants.”

The primary function of a BDU is to serve as an on/off switch to the battery based on the mode in which the EV is operating (e.g., charging or driving). According to Eaton, current model EVs rely on one of three traditional BDU configurations: fuse and contactor, pyro fuse and contactor, or fuse, pyro fuse and contactor, all combined within a single BDU. While all of these configurations provide switching and protection functions, each has disadvantages, including overall system complexity, serviceability, coordination difficulties and susceptibility to fatigue under high current levels, the company points out.

Adding Breaktor circuit protection technology to Eaton’s BDU provides extra functionality and benefits, says Eaton, including:

- active and passive actuation in a single device;

- the capability to transition to an off state under a wide range of fault conditions;

- improved functional safety;

- the ability to be reset after a high-energy fault;

- and the ability to replace up to four high-voltage electrical components, which reduces complexity and system-level cost.

The pairing of the BDU with Breaktor technology has potential to eliminate the need for as many as 15 additional system components, Eaton adds.

“Our Breaktor circuit protection technology’s self-triggering design, diagnostic electronics and mirror contact help achieve BDU functional safety goals,” Calzada said. “With its integrated coil driver, economizer and the sensing/triggering circuit, [the technology] also reduces battery management system cost and complexity.”

Breaktor technology enables up to 350 kW dc fast charging when used to protect and switch the dc fast-charge circuit, allowing EVs to charge in 15 minutes or less. This capability is made possible by recent upgrades to the technology’s thermal management and materials to boost its power capacity. The result is the ability to carry 500 amps continuously and up to 750 amps of continuous current when an active or passive cooling system is leveraged.

Current ratings can be even further increased with an appropriate cooling strategy. “Eaton is able to design and develop a compatible cooling system to customer specifications and integrated into a BDU to meet these rising power requirements,” Calzada assured.

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

CONNECT WITH THE TEAM