Eaton, Tenneco partner on exhaust thermal management system

25 March 2021

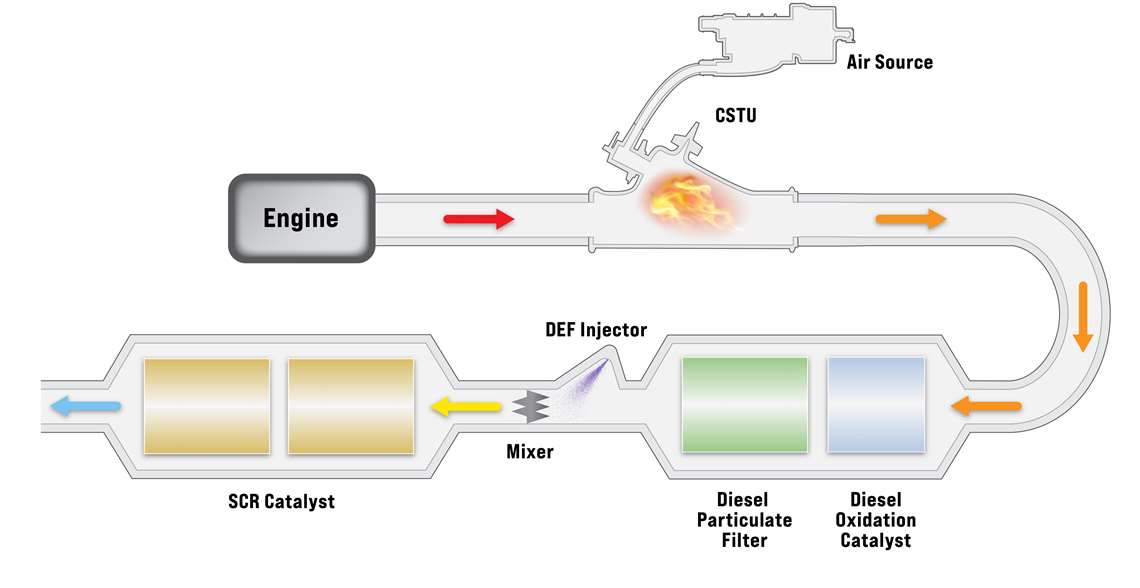

A schematic of the integrated exhaust thermal management system to be developed by Eaton and Tenneco.

A schematic of the integrated exhaust thermal management system to be developed by Eaton and Tenneco.

Eaton and Tenneco have announced a joint development agreement between Eaton’s Vehicle Group and Tenneco’s Clean Air business group to produce an integrated exhaust thermal management system designed to enable commercial truck and light vehicle manufacturers to meet upcoming emissions regulations.

“Tenneco is an established leader in the design and development of aftertreatment solutions,” said Dmitri Konson, vice president global engineering for Tenneco’s Clean Air business. “We are pleased to partner with Eaton to develop a fully optimized system for engine manufacturers, leveraging our aftertreatment technology and engineering capabilities.”

In Europe, the Euro 7 heavy-duty emissions standards are targeted for introduction in 2025, while the California Air Resources Board (CARB) and the U.S. Environmental Protection Agency (EPA) have similar actions planned for 2024 and 2027, respectively. Collectively, the new regulations are intended to reduce exhaust NOx limits by 90%, requiring global engine manufactures to employ additional emission reduction strategies.

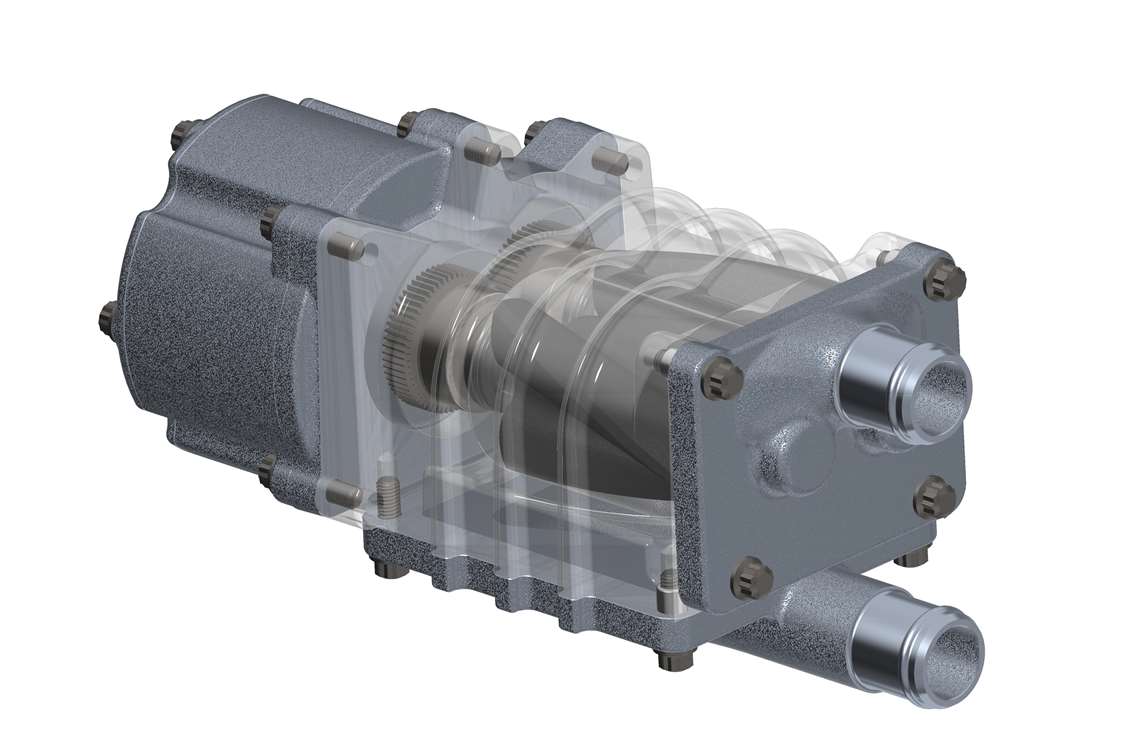

The Eaton TVS blower that will be combined with Tenneco’s Cold Start Thermal Unit (CSTU) to facilitate earlier catalyst light-off in cold engnie starting conditions.

The Eaton TVS blower that will be combined with Tenneco’s Cold Start Thermal Unit (CSTU) to facilitate earlier catalyst light-off in cold engnie starting conditions.

Under terms of the agreement, Tenneco’s Cold Start Thermal Unit (CSTU) will be combined with Eaton’s TVS blower technology to enable earlier catalyst light-off in cold-start conditions by delivering heat directly to the vehicle’s aftertreatment system. Upon heating the SCR catalyst to approximately 392 to 482º F (200 to 250º C), the aftertreatment system is able to efficiently convert NOx into nitrogen and water. Eaton’s electrically driven TVS Roots blower is engineered to precisely control the airflow so the CSTU can maintain optimal aftertreatment temperatures.

“CSTU is an active thermal management technology that rapidly heats and maintains the emission control system temperature,” said Nick Morley, director, global advanced engineering, Tenneco’s Clean Air business group. “Since the majority of emissions are generated during the initial start of engine operation and during extended idle conditions, the addition of an integrated exhaust thermal management system in front of the catalyst enables rapid light-off and efficient NOx conversion through the full range of operating conditions.”

“It became clear about three years ago that future CARB and EPA NOx regulations would be drastically stricter than they are today, and the exhaust thermal management system is an effective technology to actively heat up an aftertreatment system for commercial vehicle diesel engines to dramatically reduce cold-start NOx emissions,” said Justin Hopkins, technology development manager, Eaton’s Vehicle Group.

Eaton said the integrated exhaust thermal management system is already drawing attention from several global manufacturers. The CSTU and TVS blower will be sold individually by Tenneco and Eaton, respectively, but will be engineered as a system enabling vehicle manufacturers to seamlessly integrate the components.

Development activities will take place at Tenneco’s technical center in Edenkoben, Germany, and Eaton’s technical center in Marshall, Mich. The integrated exhaust thermal management system is anticipated to be ready for start of production in 2025 to support regulatory timing.

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

CONNECT WITH THE TEAM