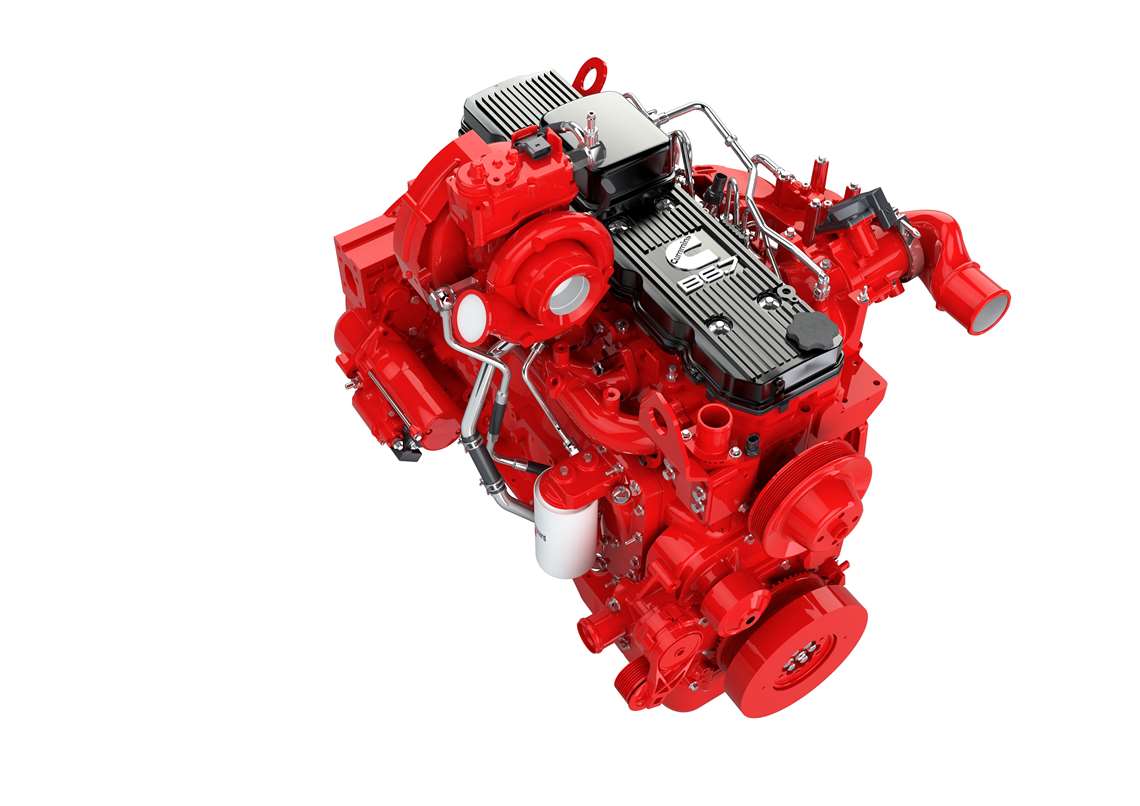

Cummins updates Stage V B6.7 engine

01 April 2021

Engine manufacturer Cummins has upgraded its Stage V B6.7 engine with Stop-Start capability, which means the model now uses 10% less fuel than its previous versions.

The Stage V B6.7 Performance Series engine is said to improve the performance of machines that need higher-speed power delivery with low-end torque capability.

The Stage V B6.7 Performance Series engine is said to improve the performance of machines that need higher-speed power delivery with low-end torque capability.

Jeremy Harsin, Cummins Off-Highway Business Director said, Harsin said, “Many machines sit idling on construction sites for long periods in between tasks.”

He added, “Stop-Start capability is included in the B6.7 to further cut fuel consumption as well as overall maintenance costs. Fuel savings should be between 5 and 10% but could be higher based on the machine duty cycle.

“This feature also delivers the sociability benefits that contractors are looking for by reducing on-site noise and exhaust emissions. Improving fuel efficiency reduces CO2 greenhouse gas emissions.”

Now known as the B6.7 Performance Series, integration of the new Stop-Start feature means the engine has been fitted with specially developed bearings and an upgraded flywheel ring and starter motor.

The model’s software has also undergone changes to accommodate the new feature.

Cummins said, its electronic control module (ECM) has been integrated with the OEM’s machine controller software, which tells the ECM when it’s safe for the machine to shut off.

It does this by monitoring the engine’s coolant temperature, intake manifold temperature, engine load, and fan operation.

“When all criteria are met, the engine will stop. The machine controller will then request an engine restart when required, and the ECM automatically restarts the engine to continue working,” said Cummins.

The updated engine is available in both Europe and North American and can be used with equipment such as crushers, screeners, wheel loaders, excavators and fork-lift trucks.

Available from 116-243 kW (155-326 hp), the latest B6.7 offers a peak torque of 1375Nm and includes Cummins’ Single Module after-treatment system.

The 6-cylinder model also includes Cummins’ Single Module after-treatment, which it said allows the engine to provide “near-zero emission levels of NOx and PM [particulate matter]” – exceeding the emissions levels required by Stage V.

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

CONNECT WITH THE TEAM