CORE engine family shifts into high speed

05 June 2023

When AGCO Power launched its CORE engine platform last fall, its initial model, the CORE75, was primarily targeted for internal use within the company’s Fendt tractor division. Now, with the addition of a second high-speed variant of the 7.5 L six-cylinder engine, the company is looking outside its corporate boundaries to other markets and applications.

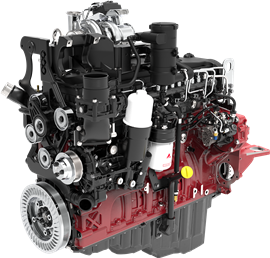

The new high-speed CORE75 engine is rated 335 hp, has a maximum speed of 2100 rpm and delivers max torque at 1500 rpm. (Photo: AGCO Power)

The new high-speed CORE75 engine is rated 335 hp, has a maximum speed of 2100 rpm and delivers max torque at 1500 rpm. (Photo: AGCO Power)

“The lower rpm version of the CORE75 was designed specifically for the use of the Fendt Vario 700 tractor,” said Jarmo Tuorila, director, sales and marketing, AGCO Power Inc. “We see… having the higher rpm engine is providing some access to other kinds of applications outside of our corporation’s own plans.”

The low-speed CORE75 introduced last October is rated 299 hp (233 kW), has a maximum speed of 1700 rpm and can deliver 1070 ft. lb. of torque at 1300 rpm. The new high-speed version is rated 335 hp (250 kW), has a maximum speed of 2100 rpm (1950 rpm nominal) and delivers max torque at 1500 rpm. Both are fully compatible with HVO fuels and will be able to use alternative fuels in future with some design and component changes.

The two engine options are part of an all-new platform that was, altogether, 10 years in the making, said Tuorila. Only a couple of minor components are shared with the company’s prior engine platforms.

“It’s an entirely new engine that is also produced on an entirely new assembly line,” Tuorila said, noting the CORE engines are being manufactured at AGCO Power’s production facility in Linnavuori, Finland. “The whole production system was optimized to produce this new engine, together with previous engine models still in production, at the same time.”

Flexibility required

Changing global regulations and emerging fuel types necessitated a new product roadmap focused on a highly flexible solution. “We already saw 10 years ago that the world is going to be changing. The environmental aspects, the sustainability issues, are very important for us. We wanted to move forward with an entirely new design for the engine technology,” Tuorila said.

That technology had to be capable of meeting pending emissions regulations in different global regions and be adaptable to fuels beyond diesel.

“HVO (hydrotreated vegetable oil) we had already been able to utilize... in the previous engine family for quite a while,” Tuorila noted. “When we are talking about alternative fuels available, we saw… that in order to build up this CORE engine family, we had to have that kind of flexibility when it comes to them moving forward [with], for example, hydrogen, methanol, ethanol, biomethane and so on.”

As such, the CORE engine family is specifically designed to be future proof, with the company planning to roll out alternative fuel adaptations over time.

“[There are] several kinds of alternative fuels that we are considering. We have our R&D department constantly working on that, and in some areas, we are already moving quite far,” Tuorila said, alluding to an introduction at Agritechnica in Hanover, Germany, later this year. “So, we certainly have quite a clear understanding of what we will be presenting in the market.

AGCO Power brought its CORE engine to ConExpo to encourage discussion with construction equipment manufacturers. (Photo: AGCO Power)

AGCO Power brought its CORE engine to ConExpo to encourage discussion with construction equipment manufacturers. (Photo: AGCO Power)

“We are moving as far as it’s reasonable and possible on our side [based on] our end customers, the different countries, the markets and also the development when it comes to emissions regulations and availability of alternative fuels.”

Learning together

The high-speed CORE75 shown at ConExpo 2023 is in production but still largely targeted for corporate use in AGCO brands, which also include Valtra and Massey Ferguson tractors. However, the purpose of displaying the high-speed version at North America’s largest construction equipment event was to explore new opportunities outside of the company and in other industries.

“The reason we are here is we want to enter in discussions with the local North American machine manufacturers,” Tuorila said of AGCO’s ConExpo presence. “We have the new engine family available – why would we not seek other partners?”

The show was also an opportunity to dispel any misperceptions about the reliability of engines originally targeted for agricultural equipment. “That kind of application is most demanding,” Tuorila pointed out. “We also have some customers in the forestry machinery and that is also a highly demanding industry for off-road engines.”

AGCO Power used the experience to educate potential customers, but also hopes to learn by working with OEMs in the industrial sector. “Development is going maybe a little faster paced simply because some of the newest technologies can be applied a little bit earlier,” Tuorila noted. “So, it’s like learning by aiming to match with the outside customers’ needs.”

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

CONNECT WITH THE TEAM