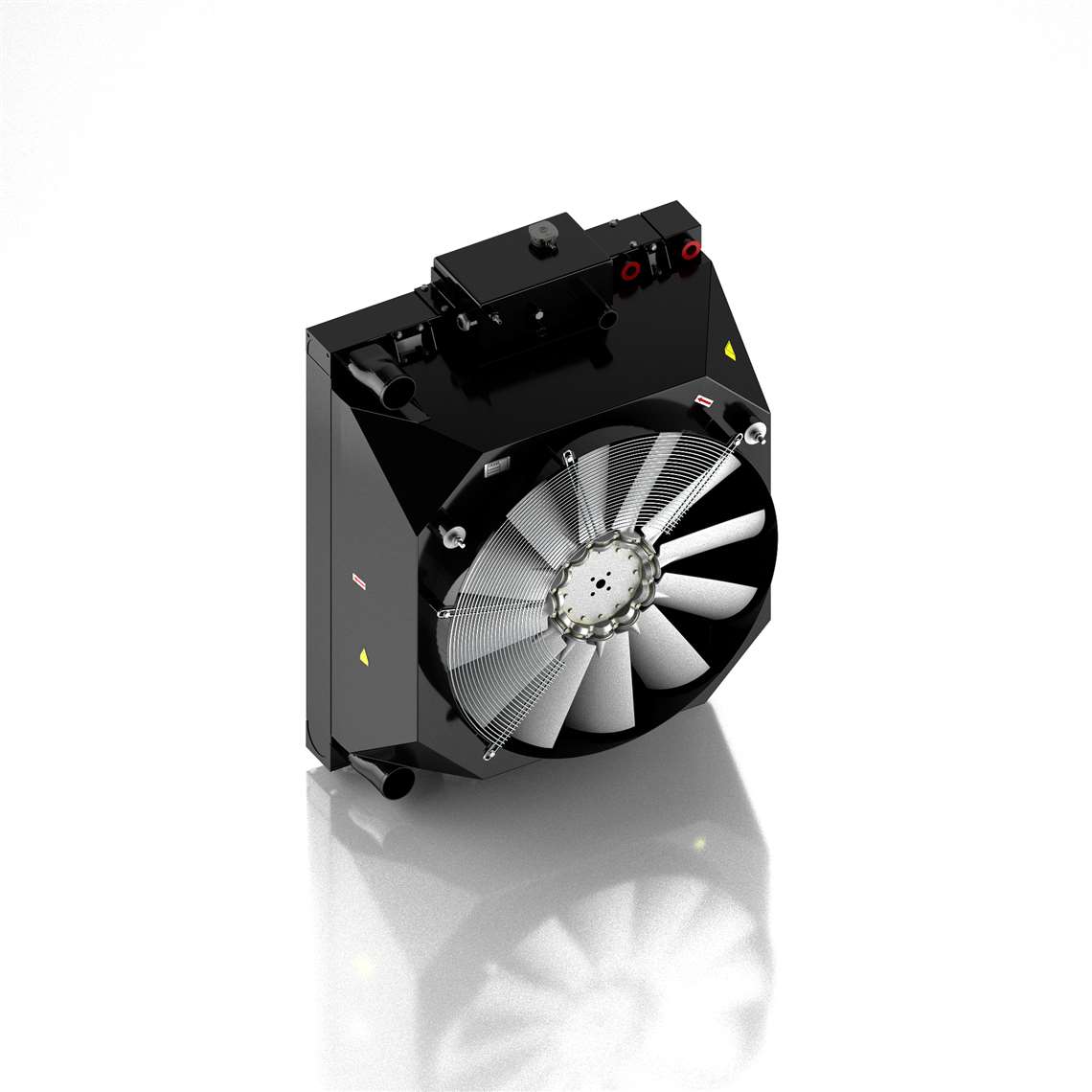

Cooling unit for demanding operation

11 April 2021

Cooling specialist Oesse designed a cooling unit for the Volvo 228-kW TAD754GE engine utilized in a crusher: a piece of equipment that continuously works in often isolated building sites and in adverse weather conditions. During the work cycle, it is not uncommon that part of the shredded debris could damage and break components inside the vehicle itself.

The Oesse unit for the Volvo TAD754GE engine features an air conveying carpentry part that is 4-mm (0.16-in) thick and guarantees extreme resistance to shocks; the protective grids are divided to guarantee the accessibility to the fan in case of breaking, while cooling cores are also divided to allow a partial replacement. The expansion tank is integrated to the water exchanger and has a 5-mm (0.2-in) thickness. These characteristics make the cooling unit specifically resistant, reinforced and do facilitate replacements, Oesse said.

You can read about Oesse’s cooling units in an article about recent product launches in Diesel Progress International, March/April issue. Click HERE to subscribe.

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

CONNECT WITH THE TEAM