Continental introduces new eRPS sensor

02 March 2023

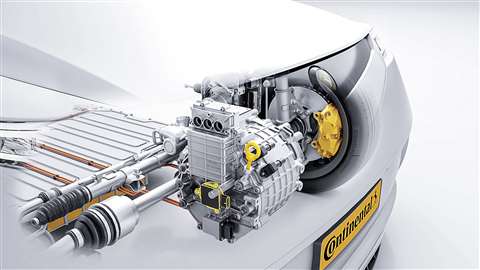

Continental’s e-motor Rotor Position Sensor is highly efficient (Photo: Continental)

Continental’s e-motor Rotor Position Sensor is highly efficient (Photo: Continental)

Continental has introduced a new sensor intended to advance the electrified powertrain market.

The high-speed inductive e-motor Rotor Position Sensor (eRPS) has the capability to detect the exact position of the rotor in a synchronous electric motor drive. This helps to increase efficiency and allow smoother operation.

Continental reports that existing solutions for rotation measurement are often based on the ‘resolver’ principle (a rotary electric transformer). These need to be adapted for use with each type of synchronous motor.

While the resolver is comparatively large, the eRPS is flat. This supports compact motor designs with a reduced overall length.

Unlike previous solutions, the new eRPS is a standardised component which can be used with any motor, regardless of pole pairs. In addition, the eRPS is reported to be more compact than existing resolver sensors, resulting in a 40% reduction in weight.

The eRPS was developed to control synchronous motors, where the rotor rotates at the same speed as the revolving field within the machine. The motor control unit needs to know the exact position of the rotor to achieve maximum motor efficiency.

The sensor design is based on the eddy current principle, which improves robustness and related mechanical tolerances. Integrated circuits (ICs) are used for signal processing. Compliant with the related ISO standard, the system allows placement of two ICs to support functional safety.

The Continental eRPS unit (Photo: Continental)

The Continental eRPS unit (Photo: Continental)

The eRPS sensor can be mounted through or at the end of the rotor shaft, including the sealing function. The module contains excitation and reception coils embedding one or to ICs that detect the electrical angular position of the metallic encoder on the rotor shaft. The weight-efficient solution delivers output in a format which requires minimal post-signal processing.

Maximum power consumption for the eRPS is 15 mA. Electrical accuracy is +/- 0.5ᵒ for a motor with four pole pairs. The unit can support rotational speeds of up to 24,000 rpm, with operating temperatures peaking at 155ᵒC.

Although traction motors are a direct use case for the eRPS, future applications could see the units used in dry brake system (without hydraulics), or brake-by-wire systems.

While the eRPS was originally developed for passenger car applications, the unit can also be successfully applied to light- and heavy-duty commercial vehicles and constuction machines using electric motors.

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

CONNECT WITH THE TEAM