Caterpillar 966 GC loader targets lower fuel and operating costs

07 June 2022

The loader’s Cat C9.3B inline six-cylinder, direct injection diesel engine is rated at 321 gross hp at 1600 rpm. (Photo: Caterpillar)

The loader’s Cat C9.3B inline six-cylinder, direct injection diesel engine is rated at 321 gross hp at 1600 rpm. (Photo: Caterpillar)

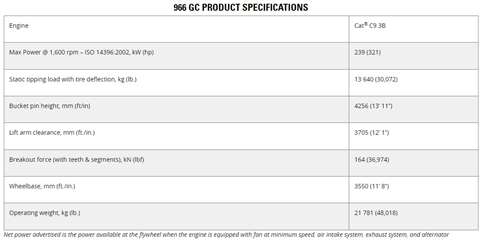

Designed for performance, durability and versatility while reducing fuel and operating costs, Caterpillar’s latest addition to its GC medium-duty equipment lineup, the 48018-lb. 966 GC wheel loader, has a Z-bar loader linkage with cast crossmember and tilt-lever that ensure strong digging capabilities and high breakout forces when equipped with the company’s Performance Series buckets. Performance specs include a static tipping load of 30072 lb., bucket pin height of 13 ft. 11 in. and breakout force of 36974 lb.

The new model’s Cat C9.3B inline six-cylinder, direct injection diesel engine is rated at 321 gross hp at 1600 rpm and meets U.S. EPA Tier 4 Final, EU Stage V, Korea Tier 4 Final, China Nonroad Stage IV and Japan 2014 emission standards. The automatic Clean Emissions Module (CEM), including SCR catalyst and diesel particulate filter, works in the background without impacting production. In addition, the Engine Idle Management System (EIMS), Auto Engine Idle Shutdown (EIS), variable speed on-demand fan and load-sensing hydraulics combine to lower fuel consumption and reduce sound levels, the company notes.

The engine is paired with a four-speed forward/reverse, electronically controlled, automatic planetary powershift transmission with shift protection for durability and single clutch gear shifting for smooth gear changes. Optional ride control improves material retention and operating smoothness over rough terrain, while optional limited slip differential axle configurations increase traction in poor underfoot conditions.

A simple, intuitive and ergonomic control system with operator interface display includes six analog-like gauges, color indicator lights and an LCD screen. Low-effort, pilot-operated implement controls include a remote transmission kick-down switch for operating comfort. The 966 GC also includes a large roof-to-floor, distortion-free, flat glass front windshield, standard rearview camera and exterior mirrors with integrated spot mirrors to ensure all-around visibility.

The available Cat Fusion quick coupler and controls can be combined with optional third-function auxiliary hydraulics to enable use of various Cat work tools. Other options include the Cat Payload Kit to provide on-the-go weighing, and an optional automatic reversing fan to assist in cleaning cooling cores in high-debris environments.

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

CONNECT WITH THE TEAM