Bosch Rexroth At IFPE

27 February 2020

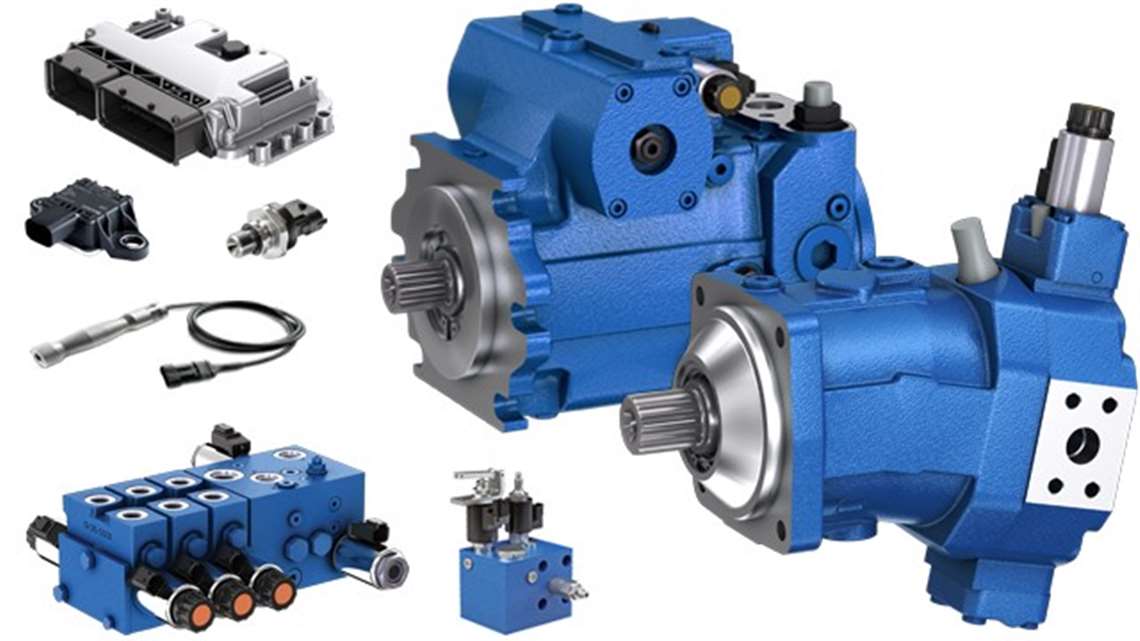

Bosch Rexroth At IFPE

As part of Bosch Rexroth’s participation in IFPE 2020, Jon Frey, head of engineering and systems solutions at Bosch Rexroth will present “The Hydrostatic Gear Drive Theory, Configuration, Operation and Suggestions Toward Best-practice Design” on Friday, March 13, 9:30-10:30 a.m. in IFPE Education Room S229. The presentation will examine how hydrostatic gear drives can be better engineered to combine existing hydraulic, mechanical and electronic technologies into unique, compact, dynamic, efficient configurations that can be designed for a singular application, or toward a serialized solution.

Bosch Rexroth’s product highlights and technology demonstrations at IFPE booth S-80215 will include:

- New RM10 and RM15 load-sensing valves: This valve platform is designed to be integrated into energy efficient systems. The product features flexible assembly with no transition plate needed between the two sizes.

- GFT 8150 tire inflation system: Harvesters with individual wheel drive can be fitted with a tire pressure control system that integrates into the harvester’s control and is managed from a standard terminal.

- BODAS RC 40 controllers for agricultural machinery: The latest generation of the BODAS RC series combines functional safety and information security with connectivity designed to support emerging agricultural autonomous application requirements.

- New EDG valve block: This modular, direct-acting valve, for implementing hydraulic functions on forklifts, features a custom manifold for mast raising and lowering, which is integrated with pre-compensated, proportional directional valves for fork, tilt and auxiliary functions.

- Snow & ice control solutions: Rexroth utilizes electronic controls and hydraulic technology in our product family of spreader controllers, which are integrated with multi-axis and multi-mode plow control systems.

- Hägglunds large hydraulic radial piston motors: Hägglunds low-speed, high torque motors are designed to deliver increased productivity and reliability for industrial, mobile and marine applications.

Each day, at the top of the hour, a Rexroth mobile technology expert will give booth presentations on the ways new technologies can help transform the performance and value of your mobile machines. Topics will address include:

- IoT connectivity: Rexroth continues to expand the capabilities and potential of its BODAS platform. Working with Bosch, we use our application know-how to convert big data in the vehicle into smart data. We send this smart data to the Bosch IoT Cloud and use it to develop valuable solutions and services by means of artificial intelligence.

- Configurable, compact hydraulics: To extend the capabilities of hydraulic equipment, Rexroth offers a range of priority flow controls and flow diverters for compact hydraulics.

- Surround sensing systems: For greater safety, comfort and performance Bosch provides a surround-sensing system that the company said enables new perspectives.

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

CONNECT WITH THE TEAM