Blue Bird flies into a new market with EV chassis

05 July 2022

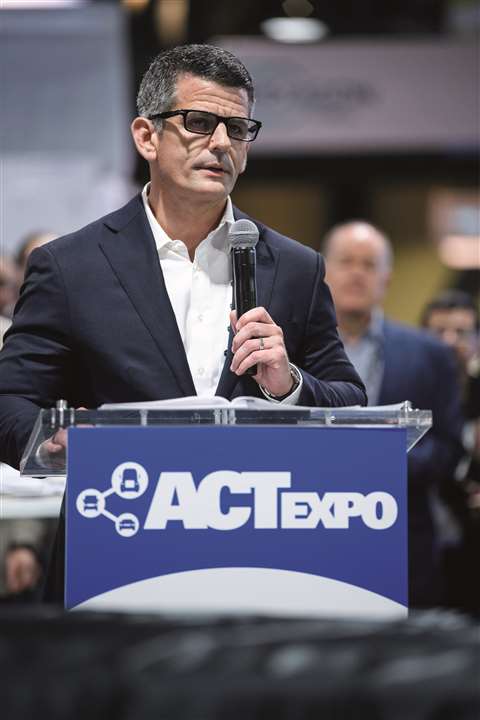

Iconic school bus manufacturer Blue Bird has unveiled an electric vehicle chassis targeting step vans and other Class 5/Class 6 vehicles such as last-mile delivery step vans, motorhomes and other specialty vehicles. (Photo: Diesel Progress)

Iconic school bus manufacturer Blue Bird has unveiled an electric vehicle chassis targeting step vans and other Class 5/Class 6 vehicles such as last-mile delivery step vans, motorhomes and other specialty vehicles. (Photo: Diesel Progress)

It isn’t often that a 95-year-old company has a chance to essentially double its business – especially organically rather than through acquisition.

That’s the opportunity that has presented itself to Blue Bird Corp. in the form of its new electric vehicle chassis platform for Class 5 and Class 6 vehicles.

Unveiled at the recent 2022 Advanced Clean Transportation (ACT) Expo, the new chassis is engineered to enable a broad range of fully electric vehicles outside the company’s traditional school bus market segment.

“Since 1927, we have built more than a half a million school buses and we’ve developed a world-class expertise in chassis engineering and manufacturing,” said Blue Bird CEO Matthew Stevenson. “We’ve come a long way over the years, increasingly transitioning to low- and zero-emissions school buses with more than 20000 propane, natural gas and electric buses in operation today.

“Now we will apply our world-class chassis-building expertise to expand our electric-powered product range to the commercial vehicle space, thereby nearly doubling our total addressable market. Blue Bird’s unique and modular vehicle platform is an industry game-changer for zero-emission mobility.”

Modular design

The new chassis incorporates a modular design, with available wheelbases of 178, 190, and 208 in. for vehicles with gross vehicle weight ratings (GVWR) up to 26000 lb. The chassis allows for several battery configurations from 70 to 225 kWh that Blue Bird said supports a vehicle range of up to 175 miles on a single charge. The battery packs take between one and twelve hours to fully recharge depending on the charging infrastructure.

“For a company that’s been in a market that’s 30000 units a year, having the potential for another 30000 units is a pretty big deal.” - Matthew Stevenson, Blue Bird CEO

“For a company that’s been in a market that’s 30000 units a year, having the potential for another 30000 units is a pretty big deal.” - Matthew Stevenson, Blue Bird CEO

The rear-wheel drive is through a Dana eS9000e electrified drive axle. Designed to be a “drop-in” to existing suspensions, the eS9000e axle incorporates an integrated motor, transmission and drive axle into a single package. The motor and inverter are water-glycol cooled and the unit can deliver a maximum power output of 317 hp (237 kW) operating at a nominal voltage of 630 to 650 V dc.

The front axle is a Hendrickson box beam style axle rated to 8000 lb., while steering is through a Douglas Autotec steering column with an 18 in. diameter wheel.

Blue Bird said it offers several safety features on its EV chassis not standard on comparable electric vehicles to enhance driver protection and familiarity. This includes “hill hold,” which prevents the vehicle from rolling backward when sitting stationary on a hill, and “electric creep,” which allows the vehicle to slowly start moving from a stop when the driver’s foot is removed from the brake pedal to simulate a gasoline engine in gear. In addition, the Blue Bird custom chassis provides the best turn radius to-date maximizing vehicle maneuverability in tight urban settings.

“We stay committed to safety as a key differentiator,” said Stevenson. “Bluebird also aims to provide a best-in-class turning radius, maximizing vehicle maneuverability in tight spaces.”

Lightning connection

Blue Bird, which first launched its electric school bus with a Cummins electric powertrain in 2018, developed its new EV chassis in cooperation with Lightning eMotors, a Loveland, Colo., supplier of electric commercial vehicles and electric drive system technologies.

“We got to know Tim (Reeser, Lightning eMotors’ CEO) a while ago and they had expressed interest in trying to tackle this segment,” Stevenson said. “Outside of Freightliner Custom Chassis, there’s no one else that’s engineering an OEM electric step van chassis.

“We make chassis all day long. We have two lines running down our plant and we have a ton of spare capacity. We’re revamping a whole new facility and enhancing our EV installation so we’ve got plenty of capacity for this.”

The new EV chassis is expected to begin production in late 2023 at Blue Bird’s manufacturing facility in Fort Valley, Ga.

“We’re excited about it,” Stevenson said. “For a company that’s been in a market that’s 30000 units a year, having the potential for another 30000 units is a pretty big deal.”

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

CONNECT WITH THE TEAM