Artificial Intelligence For Mining Fleets

22 October 2019

Symboticware Inc., a provider of standardized information-based technology designed to enhance productivity, sustainability, profitability and safety with real-time data management solutions, has announced a partnership with Uptake, an industrial artificial intelligence (AI) provider, to provide mining companies with an integrated solution to help increase the productivity of mobile mining equipment.

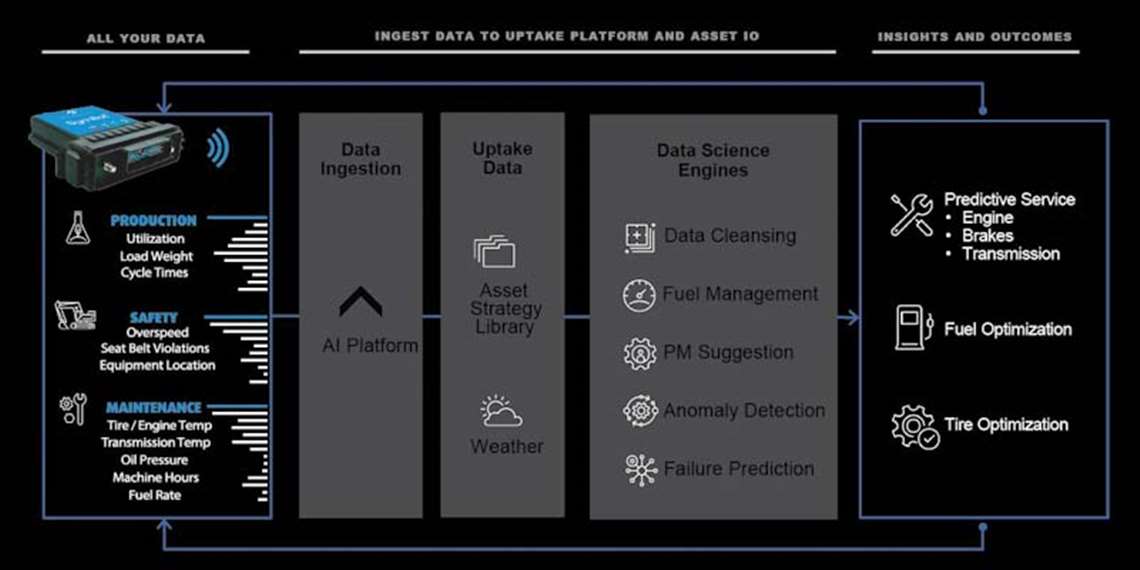

The joint solution will combine Symboticware’s SymBot device, which provides data capture from mining fleets, and Uptake’s Asset Performance Management (APM) software, Asset IO, to apply AI to extract predictive insights from the data.

“Industrial data is only as good as the insights that can be gleaned from it,” said Kirk Petroski, President and CEO Symboticware Inc., Sudbury, Ontario, Canada. “This solution delivers predictive insights that are both accurate and actionable, providing the user with sufficient lead time into maintenance issues so they can be ahead of the curve. That ability to proactively mitigate maintenance problems yields a proven, measurable increase in productivity.”

Symboticware said the combination of the two companies will give end-users:

- Data-driven cost reductions – For an average, medium-sized mining site, this joint solution reportedly save as much as $2.5 million annually in haul truck maintenance, fuel, and tire costs.

- Actionable insights for continuous improvement – Uptake’s Asset IO Mining software turns the data into actionable AI-driven insights, deploying AI models that are pre-trained to drive greater performance, reliability, and availability of the mobile mining fleet, said the company.

- Greater visibility into assets – Collect data from sensors, store time-stamped values in an internal database and seamlessly transmit data for AI analysis.

“Optimal machine health and performance is critical to getting the most out of investments in equipment and achieving a high return on capital employed,” said Ash Agarwal, director of Mining at Uptake, Chicago, Ill. “Performing regular maintenance on haul trucks can be labor- and time-intensive, with the added cost of unplanned downtime having a significant impact on throughput and operating expenses. This integrated solution provides the best of industrial IoT and AI to reduce downtime, minimize operating expenses and aid in the development of a comprehensive maintenance program.”

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

CONNECT WITH THE TEAM