AGCO Power’s engine manufacturing upgrade progressing

03 May 2021

AGCO said it is progressing with significant upgrade to the manufacturing capabilities of its engine subsidiary AGCO Power in Linnavuori, Finland.

AGCO said it is progressing with significant upgrade to the manufacturing capabilities of its engine subsidiary AGCO Power in Linnavuori, Finland.

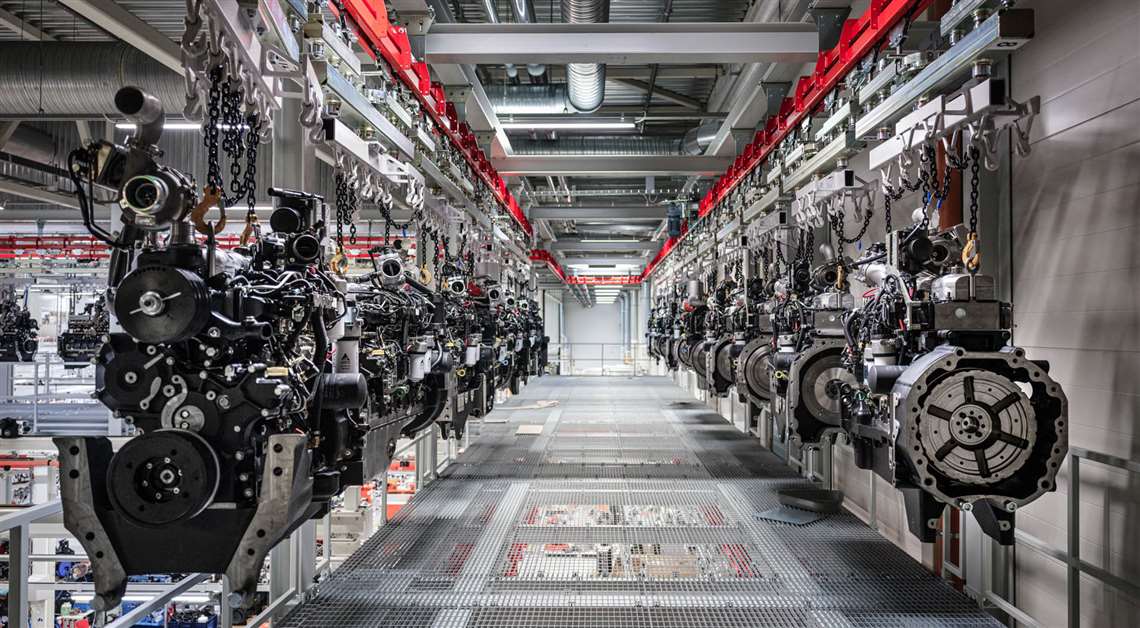

AGCO, the worldwide manufacturer and distributor of agricultural equipment and products, announced that it is progressing with significant upgrade to the manufacturing capabilities of its engine subsidiary, AGCO Power. The company initiated a €100 million-plus investment program in 2019 to strengthen the manufacturing capabilities at its engine manufacturing site in Linnavuori, Finland.

The company said a new and expanded assembly plant and a logistics center have been constructed in record time at Linnavuori, both of which are intended to help AGCO Power make its engine manufacturing process more modern and efficient.

“Despite a tight schedule and the global COVID-19 pandemic, the investment project has progressed as planned,” said Juha Tervala, CEO of AGCO Power. “The investments at the Linnavuori plant enable a more efficient and streamlined production process.

“Upgrades such as the automated logistics center and state-of-the-art robotics support improved quality, cleanliness and work ergonomics. In addition, the investment paves way for the launch of production of a new engine family by the end of 2022.”

Part of the investment was a multi-million Euro overhaul to the plant’s machining line. Once fully operational, the 100% automated machining line will enable flexible manufacturing of components in-house, reducing costs and increasing control over the production process, AGCO Power said.

“The successful completion of the project makes AGCO Power’s position in the global powertrain market better than ever,” Tervala said. “The new engine product family that is being developed will serve AGCO brands (Valtra, Fendt and Massey Ferguson) more effectively and offer future solutions to customers in the off-road machinery market.”

AGCO Power operates globally and manufactures engines at four plants: Linnavuori, Changzhou, China, Mogi das Cruzes, Brazil, and General Rodriguez, Argentina. The company, which turns 80 in 2022, has an overall engine capacity of over 100,000 engines per year.

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

CONNECT WITH THE TEAM