Vanair taps Lincoln Electric expertise for latest Air N Arc system

27 May 2022

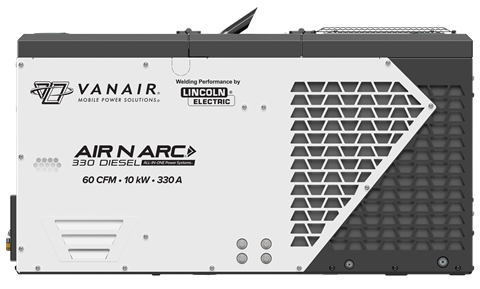

Vanair and Lincoln Electric worked together on the latest Air N Arc multi-purpose power system for work trucks. It is powered by a Kubota diesel engine. (Photo: Vanair)

Vanair and Lincoln Electric worked together on the latest Air N Arc multi-purpose power system for work trucks. It is powered by a Kubota diesel engine. (Photo: Vanair)

Vanair developed its latest Air N Arc All-In-One Power System in collaboration with Lincoln Electric, a strategic move that combined the former’s 50 years of engineering expertise in mobile air compressors, engine-starting and multi-function load management technology with the latter’s 127 years of experience with welding technology.

“It’s a rare opportunity in business when you can introduce some really magnificent products,” said Vanair Chief Executive Officer Ralph Kokot, when the Air N Arc 330 Diesel All-In-One Power System was introduced in March during NTEA’s Work Truck Week in Indianapolis. “This year, Vanair has been in this business for 50 years, and is a leader in All-In-One power solutions, and now I get to announce that we’re collaborating with the No. 1 manufacturer of weld technology on the planet, Lincoln Electric. It has been a wonderful collaboration; what an honor is has been to work with their team.”

Compared to the previous model, the Air N Arc 330 Diesel All-In-One Power System has 50% more air power, 43% more electric power, improved jump-starting performance and what Vanair called a “dramatically increased multi-process weld capability -- all in an attractive, quieter compact package.”

“Right from the beginning, it was apparent that a fantastic working relationship developed between the two companies as we went about integrating our respective technologies into an industry-leading All-In-One solution that I truly believe will set the new standard in multi-function products,” said Dean Strathman, vice president of sales for Vanair.

Automatic start/stop and engine speed control helps improve fuel savings, as well. Power comes from a water-cooled three-cylinder Kubota D902 diesel rated at 24.8 hp.

“You often hear something is the best thing since sliced bread,” said Kokot. “Well, this isn’t that. This is the machine that will repair and maintain the bread slicer. Sliced bread is good, but if you don’t have a well-maintained bread slicer, you’ve got nothing.”

Bread slicer repair technician

When bread slicing equipment repair techs pull up to the bakery, Vanair’s engineering team has worked to ensure they will be ready to tackle just about anything if there is a multi-function Air N Arc 330 Diesel installed on their service truck.

From a footprint of 47.5 L x 21.4 W x 25.6 H in., the unit provides 60 CFM of air power from the Vanair rotary screw compressor, 10 kW continuous output of AC electric power from the Lincoln Electric generator and DC multi-process arc welding with Chopper Technology. Choppers were developed for engine-driven welders to offer the same arc control offered by inverter-based welding power sources, providing what the welding manufacturer has called a more consistent arc performance. The Vanair power source is also equipped with a 330-amp 12V/24V battery booster and a 50-amp, 12V charger.

Compared to the previous model, the Air N Arc 330 Diesel All-In-One Power System has 50% more air power, 43% more electric power, increased multi-process weld capability and more. (Photo: Vanair)

Compared to the previous model, the Air N Arc 330 Diesel All-In-One Power System has 50% more air power, 43% more electric power, increased multi-process weld capability and more. (Photo: Vanair)

“This is really the ultimate evolution of a product we have so much experience with,” said Kai Justice, director of engineering, Vanair, Michigan City, Ind. “Our engineering team travels quite a bit to customer sites, which gives us a really good understanding of what our customers are doing with their machines and what they need to complete the jobs they’re doing— whether it’s jump starting, air arc gouging or running hydraulic pumps. Much of that knowledge goes into how we control the multifunction modes. There’s 50 hp of load in that machine, and we do it with roughly 20 hp of engine capability. It’s a balance to give them exactly how much air or how much weld.”

The new machine uses direct drive to run the generator rather than belt drive as in previous models, which Justice said adds as much as 5% efficiency to the package.

“In our previous package, we were directing the air and sound out the side of the unit, which made it fairly loud,” said Justice. “On this model, we’ve directed the air and the noise up. By propagating that sound dB up, it’s going away from most workers and will dissipate into space.”

Operators get a Vanair 4.3-in. electronic LCD display with pushbuttons that can be mounted directly to the machine or elsewhere on the truck.

Early connections

Kokot, who celebrates 25 years as CEO of Vanair in 2022, said his relationship with Lincoln Electric actually started early in his career.

“When we decided we were going to redesign our traditional Air N Arc product, we talked about who we wanted to work with,” he said. “Going back almost 44 years, I was an auto mechanic, and I first worked with Lincoln Electric welders in my teens. Later, when I was promoted into management for a utility company, one of my first jobs was writing technical specifications for fleet acquisitions, including specifications for pipeline welders. I listed Lincoln Electric as one of the selections along with a few other candidates. I was a young pup, so I had to submit my technical specifications to my supervisor. He came back and said to cross the others off the list because pipeline welders were the tip of the spear when it came to welding and they demand the best — Lincoln Electric. So, 44 years later, when we looked for who we were going to collaborate with there was only one option.”

Justice said, “For the hundreds of members contributing to this project, the development of this machine is more than a job, it’s a passion — to bring the world’s best All-In-One multi-function power unit to market.” He said the collaboration meant a lot of virtual meetings as well as highway time for both teams between Lincoln Electric’s Cleveland, Ohio, headquarters, and Michigan City — work that continues today.

Vanair said it expects to have the new Air N Arc 330 Diesel machine available in December 2022.

It’s been said that Lincoln Electric’s Chopper Technology can help make a professional welder better and quickly turn a novice welder into a productive member of the team. Kokot agrees: “It’s been a while since I welded, but when I welded with the Air N Arc using the Chopper Technology, I was laying out a roll of dimes like I had never put the electrode down for decades. I’m very impressed with the technology we’re offering here.”

“We can’t imagine a better offering of best-in-class solutions for this segment that we’ve been so privileged to serve,” said Phillip Fulgenzi, director of Commercial Products at Lincoln Electric. “Our two companies’ combined technologies have enabled the development of the most robust solution possible for the work truck industry.”

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

CONNECT WITH THE TEAM