How Zeus helps body builders, fleets go electric without fear

15 March 2022

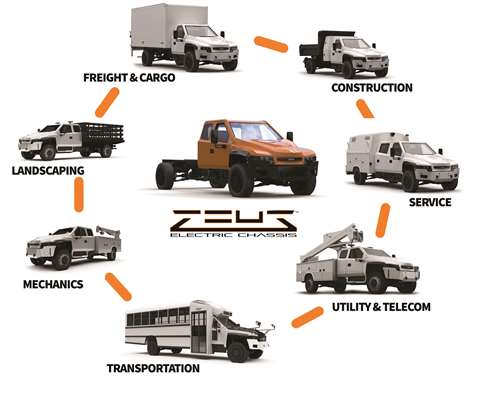

Zeus Electric Chassis talks about its practical approach to battery electric commercial vehicles.

The design of the cab-chassis permits fleets to use bodies they are already familiar with. (Illustration: Zeus Electric Chassis)

The design of the cab-chassis permits fleets to use bodies they are already familiar with. (Illustration: Zeus Electric Chassis)

The team at Zeus Electric Chassis traveled around California and Washington in late 2021 to introduce its Class 5 Z-19 truck to commercial vehicle body suppliers, dealers and fleet operators. The goal was to let folks kick the truck’s 295/60R-22.5 tires and climb up in the cab to go for a ride, but most were hesitant at first. They stood at a distance where they could take it all in.

“It wasn’t until we talked about the concept behind the truck’s modular design and named some of the major components we were using -- from suppliers they knew and were comfortable with -- that they relaxed and walked up to the truck to give it a closer look,” said Bob Grinstead, founder and Chief Technology Officer, Zeus Electric Chassis Inc. “When they saw the truck wasn’t a science experiment, they got excited and started climbing all over it.”

After years of development and validation work on the Zeus Power Platform cab and chassis unit, the White Bear Lake, Minn.-based company has officially launched its Z-19 and Class 6 Z-22 work trucks. Each model is battery powered and gets dual electric motors, all-wheel drive and four-wheel independent suspension.

“It is scary. I get it. These guys are getting forced into a situation that they don’t want to deal with. Over time they have developed a process using tools they know they can depend on. We offer a practical approach to solving those issues.” Bob Grinstead, founder and Chief Technology Officer, Zeus Electric Chassis (Photo: Zeus)

“It is scary. I get it. These guys are getting forced into a situation that they don’t want to deal with. Over time they have developed a process using tools they know they can depend on. We offer a practical approach to solving those issues.” Bob Grinstead, founder and Chief Technology Officer, Zeus Electric Chassis (Photo: Zeus)

Understandable fear

Based on decades of experience in the specialty and commercial vehicle space, Grinstead said he understands the fear many fleets have toward going fully electric. “It is scary. I get it. These guys are getting forced into a situation that they don’t want to deal with. Over time they have developed a process using tools they know they can depend on. We offer a practical approach to solving those issues.”

It’s only natural that photographs of the truck focus on the aggressive design of its impact resistant hood and fenders as well as the tested and certified aluminum “Mobile Office Space” – the cab – but photographers should compose their three-quarter shots from the rear of the machine. That’s where the work gets done, and why fleets buy such trucks in the first place. It has also been the company’s focus from the start.

From the chassis to the cab, the trucks were developed for commercial applications that depend on auxiliary equipment such as bucket and fleet maintenance trucks, refrigeration units, dump or platform trucks. The frame rails offer standard cab-to-axle (CA) dimensions (such as 60, 84 and 108 in.), so owners can install bodies they are already using on their conventional trucks.

“Yes, the truck looks cool,” said Grinstead. “But I tell people all the time to get past how it looks, because that’s not the point. The point is that we’ve got a modular power system for propulsion and also for work. The truck has some wheels and it’s got a box for a person to sit inside and drive it. When we talk about the truck with fleets and end-users, we actually want to talk about their business model and we’ll discuss the Zeus truck after that.”

Power source

Grinstead’s background is in engineering for firetruck manufacturers Spartan Motors and Rosenbauer America and as a sub-contractor for several different vehicle manufacturers. While running his engineering consultancy, he began the research and development work on an all-new battery-electric work truck. Pulling from “prior life” experience, he said developing the chassis and cab was relatively easy but finding the right power source was the challenge — the chance discovery of a new battery supplier made all the difference.

“When I started working on the design of the vehicle back in 2012 and 2013, I was looking at all sorts of battery technology – LiPo, lithium-ion – all of the stuff that was out there and getting some attention,” he said. “It was very challenging to find a manufacturer that was making complete battery packs that I could put in a vehicle and that would be safe in mobility applications. It was hard to find the right companies and really discover the truth about each system, relative to how it was manufactured, tested, and to what degree it was supported.”

While most photos will naturally capture the cab-chassis from the front, it’s at the rear where the company has placed most of its focus. (Photo: Chad Elmore)

While most photos will naturally capture the cab-chassis from the front, it’s at the rear where the company has placed most of its focus. (Photo: Chad Elmore)

In April 2019, Zeus Chief Revenue Officer Bill Brandt walked the aisles of the Bauma construction machinery trade show in Munich, Germany, and carried a shopping list of electronic components needed for the electric work truck project. He was the right man for the job, as before joining Zeus in July 2021, he was general manager of Van-Tech Corp., which provided engineered motion control system solutions for mobile on- and off-highway equipment (it was acquired by Nott Company in 2020).

Brandt said he saw Webasto Group’s relatively small stand in one of the component halls. He was impressed by the German company’s approach to lithium-ion battery system design and knew it was the right solution for the cab chassis.

“After the show we got connected to Webasto’s office in Michigan and they sent over some initial information,” said Grinstead. “Based on what they sent in their original presentation, it was obvious they knew their stuff. I had worked with Webasto in a prior life, and I knew their work with heating and cooling systems. That was a beautiful relationship to bring to lithium-ion batteries because they require a thermal management system, and it has to be bulletproof. We did a packaging study and in addition to the electronic technologies that go along with the battery pack and the service they provide, working with them made perfect sense.”

A new partner

A concept truck had already been built when Zeus CEO Wayne Kugel was introduced to Webasto’s battery pack solution. “I was stuck with the ‘innovator’s dilemma,’ that realization that there’s always going to be something newer and cooler,” he recalled, “but the more we looked into the Webasto solution the more we understood it was a game changer in regards to its modularity. It was the right decision to make the switch to Webasto’s battery solution.”

By May, Grinstead and Webasto were sharing CAD drawings, and with the batteries “fitting like a glove,” the system integration and overall design of the prototype evolved. By the end of 2020 the Zeus Power Platform was fully operational, and shortly after Zeus signed its first customer.

A service body-equipped Zeus Z-19 truck on display in the Reading booth during Work Truck Week in Indianapolis in March. (Photo: Chad Elmore)

A service body-equipped Zeus Z-19 truck on display in the Reading booth during Work Truck Week in Indianapolis in March. (Photo: Chad Elmore)

“Batteries are very nuanced,” said Grinstead. “I learned way back in the day that lithium isn’t just lithium and that all of the components that make up a battery system can create a lot of fodder out there. I really appreciate that Webasto has done their due diligence when it comes to partnering with cell providers, going all the way down to the commodity level and then back up to the service level.”

For the Z-19 cab-chassis, Webasto supplied its CV lithium-ion batteries, based on nickel manganese cobalt (NMC) chemistry, with a capacity of 105 to 210 kWh.

The baseline Z-19 offers a standard range of 150 miles. The batteries have an expected life span of approximately 3000 charging cycles, which should equate to about eight to 10 years. Level 2 and dc fast charging are supported, as well as export power capabilities to suit customer needs.

“Webasto offers what we call an off-the-shelf battery solution which presents an opportunity for a company like Zeus to get into electric propulsion without making the heavy investment of a uniquely designed battery,” said John Coon, key account manager, Battery, Webasto Thermo & Comfort North America Inc., Fenton, Mich. “Webasto has done all of the sourcing, development and testing work up front to supply a solution that is ready to go.”

A Zeus cab chassis equipped with a Knapheide stake body, as seen on display during the latter's dealer meeting in Indianapolis in March. (Photo: Chad Elmore)

A Zeus cab chassis equipped with a Knapheide stake body, as seen on display during the latter's dealer meeting in Indianapolis in March. (Photo: Chad Elmore)

Additional suppliers

The company now has a list of suppliers that includes ZF Commercial Vehicle Solutions (formerly WABCO), Meritor, Nott and Curtiss-Wright. The aluminum cabs are supplied by Marion Body Works.

Nott Company, a systems integrator company in Arden Hills, Minn., is assisting with the truck’s electronic controls, telematics, e-pump for steering and braking, on-board charging/export power and other systems.

All electrical components are protected within the chassis of the truck, including the battery pack. The chassis is equipped for the full integration of a body (mechanical, electrical, power and CAN communication) including hydraulic and pneumatic auxiliary functions. Adapting existing equipment to the Zeus Power Platform is simple and straightforward, said the manufacturer.

“You do not have to incur expensive development costs with Zeus.” said Kugel. “In the past, you had to redevelop your vocational truck tool or body to work with existing truck chassis and incur hefty engineering costs. We are going to get you into the EV party for a low cost. If you want to design something new for the future, we will support it, but if you want to get involved now, you can be ready day one.”

“That was actually our vision from the start,” said Grinstead. “On the worker side, they are already familiar with the equipment and so are the folks that have to maintain it.”

As the company’s supplier base expands, so too have its relationships with body builders. Last fall it joined forces with EAVX, a new business unit of JB Poindexter & Co. The companies will work to integrate Poindexter’s commercial truck bodies, utility truck bodies and vehicle cargo management systems (marketed under such brands as Morgan Truck Body, Morgan Olson, Reading Truck Group and Specialty Vehicle Group) with the Zeus Power Platform.

For its part, Zeus has the opportunity to leverage Poindexter’s North American footprint and nationwide body dealers to promote Zeus products. “For us, Poindexter is a channel to the market,” said Brandt. “We are body agnostic and they are chassis agnostic. Recognizing that we’re going to put on the bodies that the fleets want, from companies such as Reading, provides a mature, proven solution we can sell.”

(Photo: Chad Elmore)

(Photo: Chad Elmore)

CMC and SMUD

Zeus Electric Chassis is a client of the California Mobility Center (CMC) in Sacramento, Calif. A public-private partnership, CMC was founded less than a year ago to help start-ups overcome barriers to entry in the electric vehicle market. It serves as an innovation hub for policy, funding, and commercialization of clean transportation technologies including autonomous transportation, electric vehicles and battery storage.

Through CMC, Zeus met with the fleet managers at SMUD (Sacramento Municipal Utility District). The fleet has since agreed to purchase five of its trucks that will be used in a variety of applications throughout SMUD’s territory. It provides electricity to Sacramento county and adjoining portions of Placer and Yolo counties. It has said its goal is to transition 25% of its total fleet to electric or hybrid options by 2022.

The utility currently has a fleet comprised of 950 assets including automobiles, service trucks, bucket trucks, trailers, cable pullers and other construction equipment. It has invested in fleet electrification since 2014, but those efforts have centered on light-duty vehicles such as Chevrolet Bolts and hybrid Altec bucket trucks -- a portion of the fleet that today includes more than 100 vehicles. Before Zeus, however, the utility said its green options were extremely limited when it came to buying heavier trucks.

When the trucks are delivered to SMUD, the manufacturer will use CMC’s 25,000 sq. ft. facility for customer inspection.

The Zeus Z-19 is a Class 5 truck. (Illustration: Zeus Electric Chassis)

The Zeus Z-19 is a Class 5 truck. (Illustration: Zeus Electric Chassis)

Oklahoma is OK

In December 2021, five new cabs for the SMUD trucks were delivered to Zeus in Minnesota where they would join the chassis, batteries and other components for assembly before being shipped to California.

Assisting with that assembly was a large crew from Choctaw Defense Manufacturing, on hand to learn and document the process as that company ramps up to build trucks for Zeus. Based in Oklahoma, the company is a contract manufacturer owned by Choctaw Global LLC, a company that has typically worked with military customers. Their facilities are ISO 9001:2015 certified and encompass more than 350,000 sq. ft. of manufacturing space.

Choctaw has a full staff of manufacturing engineers, machinists, welders, painters and assemblers. When production of the Zeus Power Platform is under way there, components will ship directly from suppliers to the Choctaw facility. White Bear Lake will continue to operate as Zeus Electric Chassis’ corporate headquarters and R&D center.

The Zeus Electric Chassis was developed in Minnesota, where snow and sub-freezing temperatures are just a part of life. For fleet managers, the work must get done in spite of the weather. (Photo: Chad Elmore)

The Zeus Electric Chassis was developed in Minnesota, where snow and sub-freezing temperatures are just a part of life. For fleet managers, the work must get done in spite of the weather. (Photo: Chad Elmore)

“Our mission is to design and manufacture uncompromising, full-electric vocational solutions that address environmental and industry needs,” said Brandt. “The key there is ‘uncompromising. We will streamline the entire process so at the end of the day the fleets that are using these trucks are not compromised just because they are using an EV chassis. They are going to get what they want and more.

“We are going to give them more torque so they can do more work and have more towing capacity. They are going to do their work quietly so operators can hear and so they can think. These vehicles are built to work, so we are all about productivity and not making our customers make compromises to get their jobs done.

“To make that happen, we are doing the heavy lifting in the beginning so as we go from one platform to another, adapting new bodies will happen fast. Assembly will go quicker for the body builders, as well.

“We will partner with local upfitters using today’s bodies that customers want, and we will partner with suppliers where we need to do some development work so that we meet fleet specifications with no compromises. We haven’t found anything -- within reason -- that the cab chassis can’t accommodate. It doesn’t mean we offer a customized solution. It means we’re listening and understand that there is a TCO (total cost of ownership) model to be considered with all of these use cases.”

The prototype Zeus cab chassis parked in the warmth of the company’s White Bear Lake, Minn., headquarters. (Photo: Chad Elmore)

The prototype Zeus cab chassis parked in the warmth of the company’s White Bear Lake, Minn., headquarters. (Photo: Chad Elmore)

Long life expectancy

Fleets have reportedly been impressed with the overall robustness of the vehicle and the expected service life.

“Shuttle buses built on a standard-production medium-duty chassis might last three to five years,” said Brandt, “while the Zeus cab chassis is designed to last 10 years. It has to because the batteries will last that long.”

That lifespan is already resonating within the bus market. Zeus Electric Chassis will supply Pegasus Bus LLC four of its cab chassis, with the first delivery expected in the second quarter of 2022.

The first chassis will be used by the Lima, Ohio, start-up for to develop an electric bus prototype for demonstrations and trade shows, as well as durability testing. The cab-chassis delivery will have all-wheel drive and a conventional cab.

Zeus said each customer will have the opportunity to review the TCO model between the Pegasus-Zeus solution versus existing diesel platforms and other electric vehicle (EV) solutions, typically conversions from existing diesel platforms.

In late December 2021, the Zeus Z-19 and Z-22 electric work trucks were issued a Certificate of Conformity by the U.S. Environmental Protection Agency (EPA). “We’ve reached a tremendous number of milestones in the past year,” said Brandt, “and there is a lot happening in just the next couple of months. This team is going to be very busy in 2022.”

(Illustration: Zeus Electric Chassis)

(Illustration: Zeus Electric Chassis)

Written by Chad Elmore, this article originally appeared in the February 2022 issue of Diesel Progress.

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

CONNECT WITH THE TEAM