An Origin of cleaner engines

02 March 2021

Origin Engines licensed to use Tecogen’s near-zero emissions technology

By Mike Brezonick

Though the term “win-win” is frequently used – often overused – in today’s business world, in reality, it’s rare when any deal or arrangement truly benefits each side equally.

Still, it’s hard to see the recent agreement between Origin Engines and Tecogen as anything but a big plus for both companies.

Origin Engines and Tecogen have formed a licensing agreement that allows Origin to apply Tecogen’s patented Ultera emissions aftertreatment technology (below) on Origin’s gas engines such as the 4.3 L shown here. The engines will be aimed at a variety of mobile and stationary applications.

Origin Engines and Tecogen have formed a licensing agreement that allows Origin to apply Tecogen’s patented Ultera emissions aftertreatment technology (below) on Origin’s gas engines such as the 4.3 L shown here. The engines will be aimed at a variety of mobile and stationary applications.

Announced late last year, the licensing agreement between the companies allows Origin, the Kearney, Neb., manufacturer of gaseous-fueled engines, to utilize Tecogen’s patented Ultera aftertreatment technology on engines from 80 to 268 hp (60 to 200 kW).

For Origin, the agreement allows it to develop a range of extremely low NOx engines for mobile applications such as forklift trucks and forestry equipment, as well as stationary power systems in power generation, oil & gas and distributed energy systems.

For Tecogen, the Waltham, Mass., specialist in onsite cogeneration, heating and cooling systems, it’s a chance to expand its emissions technology into wholly new markets.

“The strategy we’ve taken to get the technology out there,” said Robert Panora, president and chief operating officer at Tecogen, “has been to first into applications that are very similar to our own products, like water pumping and stationary engines. But this moves it into mobile sources and bigger markets that we wouldn’t have access to normally.”

CUSTOMER FIRST

The licensing arrangement is the result of a confluence of events and relationship that began with Tecogen being an Origin customer.

“We started building engines for them about five years ago,” said Pete Stout, sales manager at Origin. “They started using our engines in their CHP (combined heat and power) products. We are excited now to be able to use the Ultera product with some of our other customers.”

“Basically, Ultera was originally developed for the California market,” said Abinand Rangesh, director of Corporate Strategy at Tecogen. “We realized that at some point, we wouldn’t be able to meet the CARB emissions requirements unless we had a better system to beat the NOx.

“Over time, we essentially rolled it out across our whole cogeneration fleet so now pretty much every new cogen product that gets sold out of the factory goes out with this emission package. It has allowed us, in a number of markets, to put cogen systems in without having any further testing requirements with this spec.”

“The cogeneration regulations in California required a catalyst system that would have very low NOx but also low CO and hydrocarbons, which is a bit unusual and difficult,” added Panora. “We received funding from the California Energy Commission and SoCal Gas to try to look at that issue.

“We tried big catalysts and very accurate and refined air-fuel ratio control systems and we got nowhere. The reason is that if you’re trying to convert the NOx and CO and everything in a single stage, it’s kind of a compromise. You can get real low NOx, or you can get real low CO, but getting them both down together is just trying to walk a very fine line.

“So our insight was that we would try a second stage in the system that would be fed air just upstream that would could really focus on oxidation reactions, getting rid of CO and hydrocarbons and so forth. The first stage would be relegated to NOx removal, which can be done quite well.”

A COOL SOLUTION

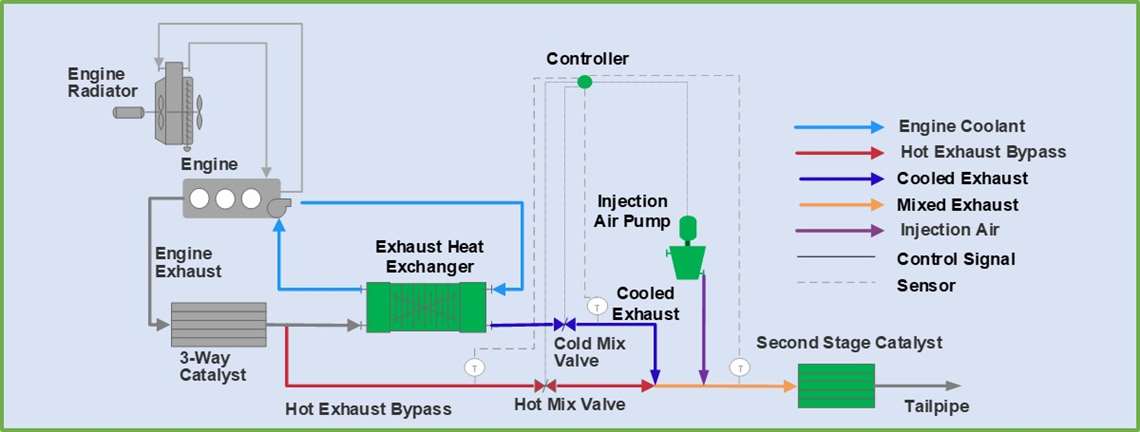

Key to the success of the two-stage configuration is that the air between the stages is cooled through use of an exhaust gas recirculation cooler mounted to the engine.

“If the second stage is at 1000° F and if you’re introducing air just upstream of that second catalyst, you’ve got a catalyst, you’ve got nitrogen, you’ve got oxygen so what happens? – you make NOx in the second stage and you’ve defeated the whole purpose,” Panora explained. “The insight we had was that if you lower the temperature in that second stage, the good reactions would still occur, the oxidation of CO and hydrocarbons was still assured, but the bad reaction – N2 plus O2 equals NOx – wouldn’t happen at a lower temperature.

“If you get the temperature in the range of 400° to 500° F in the second stage you have the good reactions proceed and the bad reactions don’t and you can really fine tune the catalysts to get very low NOx in that first stage with the consequence that CO and hydrocarbons might be a little worse, but you eliminate all that in the second stage without NOx formation.”

A schematic of the Tecogen Ultera two-stage aftertreatment system that will be used on Origin engines. The first stage reduces NOx while the temperature controlled second stage eliminates CO and hydrocarbons to near-zero levels.

A schematic of the Tecogen Ultera two-stage aftertreatment system that will be used on Origin engines. The first stage reduces NOx while the temperature controlled second stage eliminates CO and hydrocarbons to near-zero levels.

Along with the EGR cooler, the Ultera system incorporates an injection air pump, hot and cold mixing valve, a hot exhaust bypass, sensors and a controller. “It’s like a shower,” Panora said. “You can dial in the hot and cold to get the blended temperature to be the right value.”

The Ultera system was originally developed for rich-burn stationary engines, but more recently, Tecogen demonstrated its applicability for mobile applications as part of a project with PERC and Mitsubishi Caterpillar Forklifts America Inc. (MCFA). The system was upfitted and tested on a Cat forklift with a 2.5 L engine. The system was positioned under the machine’s counterweight.

While the project was temporarily halted because of the COVID-19 pandemic, “with a little bit of engine re-tuning, we were able to maintain the NOx and CO down close to zero during all operating conditions,” said Rangesh. “Even during acceleration, we had very few transient excursions.”

With the license from Tecogen, Origin is beginning the process of engineering the system onto its engines, a process that, with specification of component suppliers and testing, is expected to take up most of this year. Engines with Ultera are expected to be available in 2022, Stout said.

“Origin has grown significantly in the industrial market over the last five years and we feel that being able to give our customers the option of such emission reduction technology will only strengthen our market position,” said Shawn Sterling, chief customer officer at Origin Engines. “We see this technology playing a role in our current engine lineup of 30 to 200 kW, as well as our new products which will expand our product offering to 500 kW.”

This story originally appeared in the February issue of Diesel Progress. For a free subscription, click here.

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

CONNECT WITH THE TEAM