42nd Engine Yearbook hits top gear

16 July 2021

The 42nd Engine Yearbook, providing a snapshot of May 2020 to May 2021, is the annual reference of choice for those looking for information about leading engine manufacturers.

It is perhaps appropriate to remember, in these extraordinary times, that for four-stroke engines that the next movement of a piston from the bottom dead center position is straight up. Because that might be a fair representation of what’s happened in the North American engine industry over this past year.

The COVID-19 pandemic slammed the North American engine industry in 2020, which is outlined by the chart from global engine analyst Power Systems Research (PSR).

Total engine sales plummeted by more than five million units in 2020 from the previous year. Some segments fared better than others, but no matter how you slice-and-dice the numbers overall it is a major ouch as the industry has been badly affected.

However, looking at PSR’s forecast for 2021, it appears as if things have begun to rebound in a significant way. It will not completely make up for last year, but it seems clear that the piston is heading up from BDC.

And 2020 could have been worse, had not engine companies qualified as essential industries. That they clearly are essential is evidenced by the harvests that kept us fed, the transportation systems that had us all rolling in toilet paper and those plethora of Amazon deliveries while we cocooned at homes.

All of those things were at least in part enabled by engines working somewhere, chugging away in ag equipment, in locomotives, in marine vessels – bringing it over from faraway lands and then moving it around within the US – and of course, in all those light-, medium- and heavy-duty commercial vehicles that carry nearly 70% of all goods (including vaccines) at some point.

It would have been enough, given how the COVID-19 crisis stopped just about everything, if the engine industry had done nothing more than tread water by keeping the things that were already on the road, in the fields or on the water, moving.

They did that, but the engine companies did much more than run in place. They kept innovating, kept focusing on making their products, cleaner, more efficient. They integrated technologies such as Stop-Start, new aftertreatment systems, new controls. They found ways to make their engines even more power dense, work for longer periods between service intervals.

As the world at large struggled and some industries nearly came to a complete standstill, the engine industry persevered. See the NAFTA Engine Production projection file 2018-2021.

AMERICAN HONDA MOTOR COMPANY, INC. (AHM)

Honda Engines

Alpharetta, Georgia, USA

Web: www.honda.com

Power Range

Gasoline: 1 hp to 24.8 hp

New Engines

Honda Engines launched two all-new GC Series engines, designed specifically for pressure washers, with the Honda GCV170 and GCV200 pressure washer engines replacing the GCV160 and GCV190 models respectively.

Designed with a range of features aimed at improving long-term performance and reliability, both yield more power and torque than their predecessors. At 166 cc, the GCV170 has 18% higher torque (8.2 lb. ft.) and 9% more horsepower (4.8 hp) than the GCV160, while the 201 cc GCV200 provides 13% more torque (9.4 lb ft) and a 10% horsepower gain (5.6 hp) over the GCV190.

The Honda GCV200 and GCV170 pressure washer engines are available to outdoor power equipment OEMs.

The Honda GCV200 and GCV170 pressure washer engines are available to outdoor power equipment OEMs.

The Honda Cycloflow combustion system is engineered to enhance the air-fuel mixture and make it easier to start the engine and idle smoothly, while also making it more resilient to poor quality fuel.

New V-shaped valves and a pent-roof shape in the combustion chamber enable air in the cylinder to flow more smoothly, while a longer stroke also enhances turbulence in the cylinder and helps air-fuel mixing.

A Fuel Off position stops the flow of fuel to the engine when the pressure washing is complete. This allows the engine to run until the majority of fuel in the carburetor is consumed, preventing sticky carburetor buildup that makes for cleaner storage and easier future starting.

The addition of an Auto Choke and relocation of the wax thermostatic element from the top to the side of the cylinder improves heat transfer and makes for easier engine starting in all conditions, and enhanced balance of the crankshaft reduces engine vibration.

The engines are assembled at the Honda Power Equipment Manufacturing, Inc. facility in Swepsonville, North Carolina. They meet the SAEJ1349 net horsepower standard, which rates engine power in real-world operating conditions with the muffler and air filter in place.

The Honda GCV200 and GCV170 pressure washer engines are available to power equipment OEMs. Both carry a two-year non declining warranty and parts and services is available via the Honda national network of dealers.

ARROW ENGINE COMPANY

Arrow Engines

Tulsa, Oklahoma, USA

Web: www.arrowengine.com

Power Range

Diesel: 48.7 hp to 156 hp

Gaseous Fuel: 5 hp to 125 hp

New Engines

Arrow has launched a significantly updated version of its A54 gaseous-fueled engine. The inline 5.4 L engine is available in ratings up to 68 hp continuous/75 hp intermittent and now meets the USA EPA’s stationary and non-road mobile exhaust emissions standards, making it more suitable to a broader array of engine applications than previously.

BRIGGS & STRATTON

Vanguard Engines

Wauwatosa, Wisconsin, USA

Web: www.vanguardpower.com

Power Range

Gaseous Fuel: 6.5 hp to 37 hp

Gasoline: 4.9 hp to 40 hp

Engine News

Vanguard continues to expand its line-up of engines equipped with electronic fuel injection (EFI) and electronic throttle control (ETC).

The upcoming single-cylinder Briggs & Stratton Vanguard 400 EFI will incorporate EFI and ETC.

The upcoming single-cylinder Briggs & Stratton Vanguard 400 EFI will incorporate EFI and ETC.

The upcoming single-cylinder Vanguard 400 EFI, part of the company’s range of single-cylinder industrial engines that debuted in 2018, will be rated 14.0 gross hp and will be the latest example to incorporate EFI and ETC, which improves performance and load acceptance, offering better fuel efficiency and easier all weather chokeless starting.

The previously announced single-cylinder Vanguard 160, 200 and 400 engines all incorporate the exclusive and patented TransportGuard system, a single-switch fuel and ignition shutoff system, as well as a fully integrated cyclonic air cleaner with advanced Autoshed technology that uses engine vibrations to prevent dust buildup.

Vanguard continues to add to its broad V-Twin EFI engine range, with the most recent addition a 40 gross hp rating. The 993 cc Big Block engine also incorporates EFI and ETC, providing the same advantages of improved performance, fuel economy and load acceptance.

Vanguard also continues to expand its commercial lithium-ion battery system, which provides an integrated electric power solution for multiple applications.

Starting at a 3.8k Wh power output, battery packs are also available in a 5 kWh and 10 kWh power outputs. Vanguard batteries offer flexible power solutions so that they can be stacked to provide higher power output suited to application needs. The fully serviceable battery units also come with a battery management system and charger.

CATERPILLAR INC.

Cat Engines

East Peoria, Illinois, USA

Web: www.cat.com

Power Range

Diesel: 11 hp to 6598 hp

Gaseous Fuel: 95 hp to 8180 hp

Diesel Engines

Caterpillar Marine delivered the first Cat C32B 2433 mhp engines to Cat dealer Gregory Poole in North Carolina in spring 2021. Building on the experience gained with high performance applications, the C32B product line will be available as a 12-cylinder in a range of power options from 1800 bhp to 2400 bhp. Additional benefits include low noise and vibration levels and an easier installation process.

The Cat C32B is a 12-cylinder, vee configuration liquid-cooled diesel engine with bore and stroke dimensions of 145 x 162mm and an overall displacement of 32.1 L.

The Cat C13B meets EU Stage 5 and EPA Tier 4 final emission standards.

The Cat C13B meets EU Stage 5 and EPA Tier 4 final emission standards.

The new engine has an updated cooling system and a sequential, three-turbo air system designed to deliver faster response and better performance. Additional options include extended oil change intervals, full MCS certification, including duplex filtration, and a cosmetic engine cover. The engine complies with EPA Tier 3 Recreational and IMO II emissions regulations, with a fully integrated SCR solution for IMO III.

Cat showcased its C13B, which incorporates a non-EGR aftertreatment system while meeting EU Stage 5 and EPA Tier 4 final emission standards, at bauma China 2020. The engine offers peak power across a wide speed range, which enables OEMs to optimize machine performance based on application needs, as well as deliver high torque rise for good load acceptance.

Maintenance and Service

Caterpillar has expanded the range and scope of its engine-focused digital solutions. Cat digital services now brings complete telematics data, regardless of brand, to one easy-to-understand dashboard. This allows users quick access to important engine diagnostics and engine location, which enables engine owners to be more proactive regarding engine upkeep and maintenance.

Subscribers to Cat digital services can use the service to help avoid downtime. This is because the technology allows service personnel to patch into the engine controls, make applicable updates and have it running within a matter of hours.

Caterpillar Oil & Gas has been offering their Dynamic Gas Blending (DGB) upgrade kits for conversion of USA EPA Tier 4 Final diesel engines. The upgrade kits are available to convert both ATAAC and SCAC configurations of the Cat 3512E Tier 4 final diesel engines to the EPA-certified DGB configuration, at less than half the cost of a new engine.

Caterpillar’s Dynamic Gas Blending (DGB) technology is designed to keep displacement levels high and emissions levels low. Automatic incoming fuel quality adjustments allow DGB-optimized engines to run on various fuels including field gas and CNG, enabling lower fuel expenses for customers.

CUMMINS INC.

Columbus, Indiana, USA

Web: www.cummins.com

Power Range

Diesel: 49 hp to 4400 hp

Gaseous Fuel: 49 hp to 2680 hp

Corporate News

Cummins and Daimler Truck AG signed a memorandum of understanding establishing a global strategic partnership for medium-duty engine systems in early 2021. Cummins will invest in the further development of medium-duty engine systems for Daimler Trucks and Buses as well as the global production and delivery of medium-duty engines by Cummins for Daimler Trucks and Buses (beginning in the second half of the decade.

Cummins will establish an engine plant within the Mercedes-Benz Mannheim campus, efficiently utilizing existing resources to produce medium-duty engines compliant with the Euro 7 emissions standard for Mercedes-Benz.

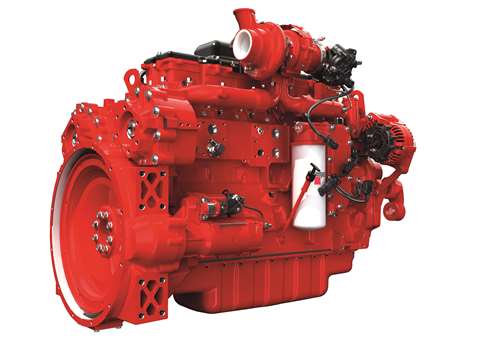

Off-Highway Engines

Cummins’ latest B6.7 Performance Series engine meets Tier 4 final emissions standards and incorporates stop-start capability which can help operators further reduce running costs as well as their environmental impact through lower noise and CO2 emissions.

The Cummins L9 Performance Series diesel engine has dual rear engine power take-offs (REPTO).

The Cummins L9 Performance Series diesel engine has dual rear engine power take-offs (REPTO).

Stop-Start capability further reduces fuel consumption as well as overall maintenance costs. It also delivers on site sociability benefits by reducing on-site noise and exhaust emissions, particularly when machines sit idling for long periods in between tasks. Along with improving fuel efficiency, the system also reduces CO2 emissions.

Stop-start has been integrated into the B6.7 platform with both hardware and software changes. Specially developed bearings in the engine along with upgrades to the flywheel ring gear and starter motor ensures long life and reliable performance with frequent starts.

Cummins’ engine electronic control module (ECM) software is integrated with the machine controller software to maintain the high levels of efficiency, productivity and safety.

The B6.7, as well as the L9 Performance Series engine, also incorporates engine power take-off (PTO) capabilities to support key applications such as cranes, crushers and screeners. The single and dual rear-engine power take-offs (REPTO) compliment their standard PTO capability. The B6.7, fitted with the dual REPTO, will have a total drive capability of 221 lb.ft. and the L9 413 lb.ft.

Cummins announced the availability of itsheir GTA855GCE and G855GCE gas compression engines that incorporate new Murphy Engine Integrated Control System (EICS), which provides a simplified set-up process and extensive diagnostics.

On-Highway Engines

Cummins debuted its latest EPA 2021 emissions compliant X12 and X15 series diesel engines for North American Class 8 truck applications in late 2020. These new engines are built on the established architecture of the 2017 engines, with a focus on increased uptime, better overall total cost of ownership and improved drivability.

Cummins has made its 2021 powertrains more fuel efficient than ever. The 2021 X15 Efficiency Series has demonstrated up to 3.5% better fuel economy compared to the 2019 product. Customers of the 2021 X12 Efficiency Series will also see improvements, with an up to 2.5% potential gain in base engine and a possible 1.5% further improvement with EX ratings.

Cummins’ 6.7L Turbo Diesel for the Ram pickup now offers a market-leading 420 hp and 1075 lb.ft. of torque. The improvements were achieved through a new calibration application to the patented sliding nozzle variable geometry turbocharger and a 29,000 psi capable fuel injection system.

DAEDONG CORP.

Daedong Engines

Daegu, Republic of Korea

Web: https://www.daedong.co.kr

Power Range

Diesel: 95 hp to 140 hp

New Engines

Daedong is launching a new 3.833 L four-cylinder diesel engine that will be used in the Kioti HX series tractor, and sold to other manufacturers in Europe and the United States. The 4J383TA engine is covered by a six-year, 3000-hour warranty.

The 4J383TA is a turbocharged and intercooled engine with a maximum rating of 140 hp at 2200 rpm and a peak torque output of 398 lb.ft. at 1400 rpm. The engine incorporates a two-layer water jacket to optimize cylinder head cooling and a higher capacity water pump for improved overall cooling performance.

It also has cooled exhaust gas recirculation (EGR), as well as a diesel oxidation catalyst (DOC), diesel particulate filter (DPF) and selective catalytic reduction (SCR) which enables it to meet EPA Tier 4 final and EU Stage 4 exhaust emissions.

DEUTZ CORP.

Deutz Engines

Norcross, Georgia, USA

Web: www.deutzamericas.com

Power Range

Diesel: 24 hp to 835 hp

Gasoline: 75 hp

Gaseous Fuel: 53.6 hp to 322 hp

New Engines

Deutz is adding a new four-cylinder diesel to its range which will go into full production in 2022. The new TCD 5.2 L04 is a 5.2 L inline engine, a compact replacement for larger six-cylinder engines, offering a maximum rating of 228 hp and 700 lb.ft. of torque.

The Deutz TCD 5.2 L04 is a 5.2 L inline engine designed to serve as a compact replacement for larger six-cylinder engines.

The Deutz TCD 5.2 L04 is a 5.2 L inline engine designed to serve as a compact replacement for larger six-cylinder engines.

The TCD 5.2 incorporates an advanced combustion system that enables it to eliminate exhaust gas recirculation (EGR). With aftertreatment – DOC, DPF and SCR – the engine meets EPA Tier 4 final, EU Stage 5 and China 4 emissions regulations, but the engine is also available without aftertreatment for lower-regulated markets.

It can run on alternative fuels such as biodiesel and is also optimized for hybrid applications. The engine is offered with a range of options, including compact radiators, along with various oil pan, flywheel and fan positions. The service interval is 1000 hours.

New Engine Ratings

The TCD 2.9 diesel is offered in high-power and high-torque versions.

The high-power version offers ratings to 100 hp for Stage 5 applications, while the high-torque engine is rated 75 hp with 277lb ft of torque, 25% more torque than the standard engine. These engines offer 100% power take-off at the flywheel and front end, along with an additional side PTO drive that allows mounting of two hydraulic pumps.

Emissions Technology

A more compact aftertreatment system for Stage 5 applications has been developed. This system integrates the SCR mixing unit into the DPF module, which eliminates the separate mixing pipe and reducing the overall size of the aftertreatment package.

Alternative Fuels

Three- and four-cylinder engines are available, designed to operate on liquid or gaseous fuels. Both engines (G 2.2 at 2.2 L and G 2.9 at 2.9 L) incorporate three-way catalyst aftertreatment and meet EPA Tier 2 and EU Stage 5 emissions regulations. The G 2.2 engine can operate on LPG or natural gas, with ratings to 56.4 hp. The G 2.9 engine is a four-cylinder engine that can operate on LPG, gasoline or in bi-fuel applications.

Corporate News

Deutz and John Deere Power Systems (JDPS) have announced plans to jointly develop and source components for a low horsepower range engine up to 174 hp. The co-development and co-sourcing scope include engine hardware and design, from which each company will customize its product to meet customers’ specific needs through engine software and controls. Engine manufacturing and distribution will be done independently by Deutz and JDPS.

Distribution News

Deutz Corp. opened a 160,000 sq. ft Sequence Center at Pendergrass (just a mile away from the company’s production facility) in mid-2020. The Sequence Center stores all of the parts and engines for Deutz Value-Add products and Xchange remanufactured engines, and delivers them as needed to the production facility. The facility also has its own production capabilities, building and shipping value-add kits and customized Deutz Power Packs to distributors, dealers and OEMs.

Deutz Corp. announced in spring 2021 the latest addition to its Deutz Power Center network, Deutz Power Center Mid-America in the Dallas-Fort Worth area. This new facility offers a fully stocked parts counter and provides regularly scheduled and emergency service of Deutz engines, either at the Power Center location or at the customer’s site via remotely-located service technicians.

Deutz Power Center Mid-America will also provide dedicated application engineering and technical sales resources for OEMs that utilize Deutz products in their equipment. Power Center customers can also purchase new Deutz engines, as well as Deutz Xchange remanufactured engines.

DOOSAN INFRACORE

Doosan Engines

Itasca, Illinois, USA

Web: www.doosaninfracore.com

Power Range

Diesel: 9.38 to 1334 hp

Gaseous Fuel: 171 to 605 hp

ENGINE DISTRIBUTORS INC. (EDI)

EDI Engines

Blackwood, New Jersey, USA

Web: www.edi-dist.com

Power Range

Gaseous Fuel: 25 hp to 250 hp

Gasoline: 25 hp to 250 hp

New Engines

EDI plans to launch two new natural gas engines in 2021. The LSG365 is a 3.5 L V6 engine expected to launch in Q3 2021.

With ratings up to 115 hp on LPG, it can also operate on LPV (LP vapor) and natural gas. A gasoline version will be available in 2022. EDI will unveil the 7.3 L WSF873, a V8 engine rated up to 245 hp on LPG, in Q4 2021. A gasoline version of the engine will launch in 2022, along with a turbocharger configuration that can operate on natural gas, LPG or LPV.

FAIRBANKS MORSE DEFENSE

Fairbanks Morse Engines

Beloit, Wisconsin, USA

Web: www.fairbanksmorsedefense.com

Power Range

Diesel: 1064 hp to 25,745 hp

Gaseous Fuel: 2100 hp to 4,865 hp

Alternative Fuels

Alternative fuel testing has been conducted on their own engines to support the US Navy Energy Goals Initiative. In partnership with Life Cycle Engineering, the company that is under contract as part of the Navy’s alternative fuel testing program, Fairbanks Morse developed protocols and tested the viability of several alternative fuels for use in two of its engines.

The objective was to qualify alternative fuels that will meet all of the US Navy’s current fuel specifications and make them suitable as “drop-in” fuels used in the fleet without making costly changes to the engines and infrastructure.

Testing has been done on biofuel alternatives for two of the fuels commonly used by the Navy, F-76 (diesel) and JP-5 (jet fuel). That included three separate alternative F-76 biofuel blends for the FM 38D 8 1/8 engine and an alternative JP-5 biofuel blend on the FM PA6B engine.

Corporate News

Engine maker Fairbanks Morse has rebranded itself as Fairbanks Morse Defense (FMD). The move reflects the company’s emphasis on service to its military and commercial maritime customers, with a broader range of aftermarket service solutions.

FMD consists of three divisions, namely Fairbanks Morse Engine (FME), Fairbanks Morse Service (FMS) and Ward Leonard (WL). Located in Beloit, in a facility separate from FMD, FME manufactures, procures, assembles and distributes all Fairbanks Morse engines.

FMS provides all aftermarket parts, services, and solutions for both military and non-governmental customers. Breco International Inc., a specialty provider of ALCO parts and services recently acquired by Fairbanks Morse (FM), falls within the FMS division. Ward Leonard (WL), acquired by FM in January, is a provider of motor and control solutions for military applications and has been a major supplier to the US Navy for more than a century.

Along with Breco and WL, Fairbanks Morse also acquired the assets of Globe Turbocharger Specialties, Inc., a global manufacturer of turbochargers and parts. The acquisition included all assets and intellectual property of Globe Turbocharger Specialties related to Alco, EMD, and GE diesel engines.

FPT Industrial Engines

Burr Ridge, Illinois, USA

Web: www.fptindustrial.com

Power Range

Diesel: 38 hp to 1000 hp

Gaseous Fuel: 75 hp to 460 hp

Alternative Fuels

FPT Industrial is testing dimethyl ether (DME) as an alternative fuel for compression ignition engines. The research, which involves testing the fuel with an FPT Industrial 11 L heavy-duty diesel engine, is being done in an effort assess the potential of alternative fuels and e-fuels in reaching the European CO2 emission targets in 2025 and 2030.

FPT Industrial F28 four-cylinder gas engines include three-way catalyst aftertreatment.

FPT Industrial F28 four-cylinder gas engines include three-way catalyst aftertreatment.

FPT Industrial supplied F28 natural gas engines for two New Holland TK Methane Power crawler vineyard tractors, powered by biomethane and utilized at the Fontanafredda winery at the Piedmont region in Italy.

These tractors are part of a project with the wine producer to produce the first 100% sustainable wine. The four-cylinder F28 gas engines are rated 74 hp and include three-way catalyst aftertreatment. The two biomethane tractor prototypes use biomethane produced locally from the anaerobic digestion of agricultural waste.

Distribution News

FPT North America continues to develop its network of distribution partners. Recent additions include: Kraft Power/Merex for Mexico and the southern US; MSHS Group for the East Coast, Lower Inland Waterway, Caribbean Islands, Alaska, and Hawaii; Smith Power Products Inc. for the Western US, and; Stauffer Diesel for the Great Lakes and Upper Inland Waterway region.

Emissions Technology

FPT Industrial has developed a second generation of its patented HI-eSCR emissions aftertreatment technology, designed to reduce NOx emissions levels by more than 95%. The new HI-eSCR 2 system is applicable to engines over 75 hp and below 750 hp, and it maintains the same dimensions as the current Tier4 final/Stage 4 technology.

Engine News

FPT Industrial is turning its vision for the off-road powertrain of the future into reality with the unveiling of the F28 Hybrid, a 2.8 L diesel engine paired with an e-flywheel to deliver what the company said is an efficient, compact and sustainable solution for off-road applications. The four-cylinder engine, developed for compact machine applications, delivers up to 74 hp while the electric motor adds 27 hp of continuous power and 40 hp of peak power.

Marine Engines

FPT Industrial has expanded its marine engine lineup for leisure and commercial applications. The company launched its new C90 170 Stage 5 diesel for heavy-duty applications, which incorporates an optimized fuel map that provides a 30% reduction of HC, NOx and PM emissions from previous engines.

The N67 450 N engine is new for the Europe and North America market. Rated 450 hp at 3000 rpm, it complies with EPA and IMO emissions regulations and incorporates enhanced cooling and improved fuel injection at cold temperatures.

FPT has also adopted keel cooling on its N40 250 E, N67 450 N and N67 570 EVO engines. Major benefits include protection of the engine from the seawater corrosion, avoidance of continuous seawater filter obstruction, and frequent demages to the seawater impeller. FPT Industrial’s marine engine range is composed of eight engine families, from 85 hp to 1000 hp (62 kW to 735 kW).

Maintenance and Service

FPT Industrial recently expanded its products and services portfolio with the launch of a new line of high-performance lubricants. These FPT Industrial Genuine Engine Lubricants, developed to ensure maximum fuel efficiency, are suitable for all off-road, power generation and marine engines. Formulations available include 0W-40, 10W-40 and 15W-40 oils.

HATZ DIESEL OF NORTH AMERICA

Hatz Diesel Engines

Waukesha, Wisconsin, USA

Website: www.hatznorthamerica.com

Power Range

Diesel: 6 hp to 86 hp

New Engines

Hatz will be significantly expanding its range of flywheel-integrated permanent magnet generator (fiPMG) engines this summer. The fiPMG engines consist of an electronically-controlled E1 single-cylinder diesel with a compact PMG incorporated into the flywheel, resulting in a package that is more than 12 inches shorter and as much as 37 lb. lighter than conventional engine-generator designs.

The Hatz fiPMG diesel engines are electronically controlled.

The Hatz fiPMG diesel engines are electronically controlled.

The new dc engine ratings include the PMDC-28-100 (2.8kW), PMDC-28-200 (5.6 kW) and PMDC-56-60 (3.4 kW), PMDC-56-100 (5.6 kW). New ac units are the PMAC-230/5-3.0 (3 kW at 50 Hz), PMAC-120/6-1.6 (1.6 kW at 60 Hz) and the PMAC-120/6-3.5 (3.5 kW at 60 Hz.)

Hatz said new engine ratings are being developed for its H50 Series turbocharged diesel engines. The new ratings will include additional ISO fuel stop power (IFN) ratings for intermittent loads and ISO standard continuous to meet ISO 3046-1 standards.

Service and Warranty

Hatz has continued to expand its North American Service Dealer Program, first initiated in 2020. The program establishes three levels of servicing dealers – Gold, Silver and most recently, Bronze, that provide varying degrees of capability.

Gold dealers can perform service and warranty work on the entire range of Hatz mechanical and electronic engines. With a high standard for training, tooling and stocking, they are eligible to purchase engines and parts at a specified discount. Silver dealers perform service and warranty only for Hatz mechanical and electronic air-cooled engines. They also receive discounted parts and accessories specific to the engines they support. Bronze dealers are also authorized to support only Hatz mechanical air-cooled engines and receive discounted parts and accessories.

INNIO WAUKESHA GAS ENGINES

INNIO Waukesha Engines

Waukesha, Wisconsin, USA

Web: www.innio.com

Power Range

Gaseous Fuel: 160 hp to 5000 hp

New Engines

INNIO Waukesha Gas Engines has released a higher-output, standby version of its VGF engine, known as the P48SE. The 16-cylinder, rich-burn engine is part of the company’s plans to refresh its VGF product line, designated for gas compression and power generation applications.

The 48L P48SE engine is rated 1460 bhp at 1800rpm for up to 200 hours per year at 70% load factor. It has an emergency standby power rating of 1460 bhp (1100 kWb) per ISO 8528-1, which allows for a net electrical power rating of 1 MW. The new engine comes with INNIO Waukesha’s updated ESM2 controls system, which consists of an enhanced electronic control unit, a 12-inch touchscreen human machine interface (HMI), ignition module (IPMD2), flange mounted ignition coils, electronic fuel valve, pre-catalyst wideband oxygen sensor and an electric starter.

The P48SE is initially available for 60 Hz applications, running on commercial quality natural gas. Initial engine shipments began in 2021 with open gen-set and radiator-mounted gen-set offerings set to follow.

ISUZU MOTORS LTD

Isuzu Engines

Plymouth, Michigan, USA

Web: www.isuzuengines.com

Power Range

Diesel: 8.9 hp to 532 hp

Gaseous Fuel: 78.4 hp to 79.79 hp

LPG: 56 hp to 82 hp

Engine Packages

Isuzu has expanded its range of open diesel engine power units engineered to save standby generator set manufacturers time, money and engineering resources.

The Tier 4-certified Isuzu 4JJ1X power units are are based on the company's REDTech Tier 4 and Stage 5 diesel engines.

The Tier 4-certified Isuzu 4JJ1X power units are are based on the company's REDTech Tier 4 and Stage 5 diesel engines.

Its newest Tier 4-certified 4JJ1X power units are based on a 3.0 L engine rated 95 hp at 1800rpm. The power units are pre-tested and more than 90% validated, resulting in less engineering work for the customer.

All of the power units are based on Isuzu’s line of Reliable, Eco-friendly, Durable and Technologically Advanced (REDTech) Tier 4 and Stage 5 diesel engines. Available in ratings from 8.9 hp to 532 hp, the engines utilize a robust fuel injection system.

The power units also offer packaging flexibility with horizontal or vertical aftertreatment systems, including an over-the-flywheel selective catalytic reduction (SCR) system.

Aftertreatment can be packaged in a range of configurations using common components, and other options include adjustable skid base cross members for bolt-on flexibility.

The company’s alternative fuel engines can also be supplied as power units operating on natural gas or propane.

They can also be equipped with a dual-fuel system that allows the user to reconfigure the fuel source quickly and with no downtime. The Dual-Fuel Power Units can be switched off and restarted with a flip of a switch to change the fuel type.

JCB POWER SYSTEMS

JCB Engines

Derbyshire, England

Web: www.jcb.com

Power Range

Diesel: 74 hp to 284 hp

New Engines

JCB Power Systems has launched a further series of EU Stage 5 compliant diesel engines, which meet the latest emissions regulations while also delivering on customer demand in specific markets and applications.

The JCB 448 Stage 5 engine, available in four power nodes from 108 hp to 173 hp, is part of the Stage 5 G-Drive range.

The JCB 448 Stage 5 engine, available in four power nodes from 108 hp to 173 hp, is part of the Stage 5 G-Drive range.

Building on the success of its 74 hp Stage 5 430 engine, JCB Power Systems has introduced an additional range of higher output variants designed for off-highway applications in both stationary and mobile industrial equipment and generators.

The new 448 Stage 5 engines are available in four power nodes from 108hp to 173hp with peak torque outputs from 380 lb.ft. to 509 lb.ft.

Designed primarily for European generator applications, the new Stage 5 G-Drive models are available in four engine power nodes spanning from 95 hp to 131 hp, for generator outputs of 80kVA to 110kVA prime.

The latest Stage 5 range builds on the success its predecessor – the 448 JCB engine – which is proven in OEM installations across Europe, North America and the global market, the company said. Efficiency is the key focus and the new models deliver low fuel consumption, reducing carbon dioxide and other exhaust emissions.

Application-specific solutions have also been developed, including the release of the Stage 5 Inland Waterways Auxiliary (IWA) engines range used for power generation on board vessels. Currently available in two power nodes, the 448 TGWA delivers either 60 kWe (65 kVA) or 72 kWe (79 kVA) at 1500 rpm. The engines meet the emissions standards for this application without the need for aftertreatment and with a mechanical fuel system.

JOHN DEERE POWER SYSTEMS (JDPS)

John Deere Engines

Waterloo, Iowa, USA

Web: www.JohnDeere.com

Power Range

Diesel: 48 hp to 684 hp

Alternative Drivetrains

John Deere is continuing its commitment to helping OEMs implement electrified system architectures. John Deere offers engine, drivetrain and electronic solutions, with hybrid architectures that have accumulated more than two million operating hours in the field.

Successfully implementing alternative power systems in off-highway equipment will depend on being able to optimize an overall power solution that balances mechanical, hydraulic and electric power systems, along with cost. John Deere can offer a broad range of expertise in mechanical and electronic solutions, which directly contributes toward robust, reliable alternative power architectures.

Connectivity

John Deere has introduced its Smart Industrial strategy, which is intended to unlock new value for customers and help them become more profitable and sustainable while simultaneously revolutionizing the agriculture and construction industries through the rapid introduction of new technologies. As a part of that strategy, Deere utilizes the Internet of Things (IoT) and machine performance data to develop new solutions through John Deere Connected Support.

Engine News

John Deere Power Systems (JDPS) and Deutz have announced plans to jointly develop and source components for a low horsepower range engine up to 174 hp.

The John Deere 18.0L, set for production in 2022, incorporates new combustion technology with fixed and wastegate turbochargers.

The John Deere 18.0L, set for production in 2022, incorporates new combustion technology with fixed and wastegate turbochargers.

The co-development and co-sourcing scope include engine hardware and design, from which each company will customize its product to meet customers’ specific needs through engine software and controls. Engine manufacturing and distribution will be done independently by JDPS and Deutz.

New Engines

Building on its 13.6L diesel that was named the Engine of the Year over 175 hp at the 2020 Diesel Progress Summit & Awards, John Deere has unveiled its new 18.0L engine.

Set to begin production in 2022, the largest engine in the company’s line offers a top rating of 870 hp and was designed with flexibility, serviceability and durability in mind.

This 18.0L engine incorporates new combustion technology with fixed and wastegate turbochargers as well as exhaust gas recirculation, which allows the engine to meet emissions requirements without aftertreatment. The high-pressure common rail fuel system provides superior fluid consumption and model-based controls enable advanced prognostics capabilities and improved transient response.

KAWASAKI MOTORS CORP., USA

Kawasaki Engines

Grand Rapids, Michigan

Web: www.kawasakienginesusa.com

Power Range

Gasoline: 14.5 hp to 38.5 hp

Distribution News

Kawasaki announced an agreement with two affiliated companies to assume import and distribution activities in Mexico as part of its continuing efforts to provide maximum support to its OEMs in Mexico. Tecnologia En Riego De Mexico (TERMSA) and Tecnologia Integral En Riego (TIRSA) will geographically split responsibilities for the country, based on a north-south division of its numerous states.

TIRSA, based in Guadalajara, will service the area of Mexico that lies roughly north of Mexico City to the US border, including Baja. TERMSA, with headquarters in Mexico City, will focus on the area roughly south of the capital. Its administrative, sales and technical staff will work with dealers and the landscape industry in that 14-state area. Each of the companies will import and market replacement engines and parts, as well as provide warranty and technical support.

New Products

Kawasaki has launched two new ethanol-free fuel products specifically optimized for outdoor power equipment (OPE) applications. The new additions to the company’s Signature Series family of products are the KTech Blend Pre-Mixed 2-Cycle Fuel + Oil and KTech Ethanol-Free 4-Cycle Fuel.

The Ktech Pre-Mixed 2-Cycle Fuel + Oil is engineered to avoid the inherent issues attached to pump fuel that is formulated for the transportation industry. The new blend is intended to take the guesswork out of the oil and fuel mix for two-cycle equipment. and contains 93 octane gasoline and 100% synthetic blend FD certified oil in a 50:1 mix. While contributing to improved engine cleanliness and reducing carbon buildup, port blockages and ring wear, the mixture is extremely stable and will last two years in a tank and five years in a sealed container.

The new unleaded KTech Ethanol-Free 4-Cycle Fuel is formulated for four-cycle small gasoline engines and two-cycle engines when mixed with oil to engine manufacturer specifications.

KEM EQUIPMENT

Kodiak Engines

Tualatin, Oregon

Web: www.kemequipment.com

Power Range

Gaseous Fuel: 42 hp to 233 hp

Gasoline: 43 hp to 104 hp (industrial)

Gasoline: 120 hp to 505 hp (marine)

Engine News

KEM’s 6.2L LT4 Kodiak marine engine is now available with an Eaton R1740 TVS supercharger, which operates at up to 20,000 rpm and generates as much as 9 lb. of boost. That enables the small block V8 to generate 650 hp and 650 lb.ft. of torque at 6600 rpm, KEM said. All of the Kodiak engines use the GM Marine Engine Fuel Injection (MEFI) engine control module (ECM), which brings automotive reliability, low emissions and fuel savings to the marine sport engines.

On the industrial engine side, KEM offers mobile engines from 3.0 L to 8.0 L in ratings from 21.9 hp to 247 hp that operate on LP or natural gas. Stationary engines range from 3.0 L to 10.3 L, with ratings of 17 hp to 198 hp.

KOEL AMERICAS CORP.

Kirloskar Oil Engines

Magnolia, Texas

Web: http://koel.kirloskar.com

Power Range

Diesel: 4 hp to 1250 hp

New Engines

KOEL Americas Corp. is the wholly owned subsidiary of Kirloskar Oil Engines Ltd (KOEL) of India. KOEL Americas, established in 2015, was founded to compete in the North American and Latin American markets.

The KOEL 4R810NA1 is a 3.24 L four-cylinder naturally aspirated diesel engine.

The KOEL 4R810NA1 is a 3.24 L four-cylinder naturally aspirated diesel engine.

The company has a number of products in development that are scheduled to be released for North American market this year and in 2022.

This includes a new platform of 0.55 L/cyl engines in two-, three- and four-cylinder variants covering an output range of 10 hp to 74 hp. The 1.1 L, 1.65 L and 2.2 L R550 series engines were previewed at ConExpo-Con/Agg 2020 and will be released certified to EPA Final Tier 4 emissions standards for various off-highway applications.

The engines under 25 hp will incorporate mechanical fuel pumps, while the engines between 25 hp and 74 hp will utilize common rail fuel injection, along with cooled exhaust gas recirculation (EGR) and diesel oxidation catalyst (DOC) aftertreatment. KOEL is also planning to introduce four-cylinder, 4.8 L diesels rated 75 hp to 130 hp at a later date.

KOEL’s existing product line for North America comprised three engine families with a total of four engine models. The 4R810NA1 diesel is a 3.24 L four-cylinder naturally aspirated engine rated 48.7 hp. The next two models share the same configuration as the 4R810NA1, but add turbocharging and aftercooling. The 4R810TA1 is rated 95 hp while 4R810TA2 is rated 65 hp. The largest engine in the current lineup is the 4K1080TA1, a 4.33 L four-cylinder turbocharged and aftercooled diesel rated 156 hp.

Also available from KOEL Americas is Kirloskar’s KFP Series diesel engines for fire pumps. The engines are FM Global (FM) approved and Underwriters Laboratories (UL) Listed, and are available in 38 different ratings from 55 hp to 336 hp.

Packaging of fire pump engines with base frames and other accessories has recently been started in partnership with Arrow Engine Co. in Tulsa, Oklahoma, which ensures complete package can be delivered to fire pump OEMs with very short lead times.

Distribution News

KOEL Americas has plans for five distributors to handle the US, supported by the Houston-area office for sales and warranty work as well as the parent company in India. Distributors may order container loads of engines from India or top-up orders from the warehouse in US. Product training, including “train the trainer” programs, will take place at the distributor’s location, KOEL Americas headquarters or at the parent company’s location in India.

KOHLER

Kohler Engines

Kohler, Wisconsin

Web: www.kohlerengines.com

Power Range

Diesel: 3.4 hp to 141 hp

Gaseous Fuel: 18 hp to 39.9 hp

Gasoline: 1.34 hp to 38 hp

New Engines

Kohler announced the launch of a pair of new Command Pro EFI propane engines. The new PCV680LE and PCV740LE engines are twin-cylinder, vertical-shaft engines designed to significantly reduce exhaust emissions.

Closed-loop EFI technology allows the Kohler Command PRO PCV680LE to automatically adapt to operating conditions.

Closed-loop EFI technology allows the Kohler Command PRO PCV680LE to automatically adapt to operating conditions.

An alternative to gasoline and diesel engines, these new propane engines are a cleaner-burning, more fuel-efficient alternative for commercial equipment. Through the combination of electronic fuel control which optimizes fueling and an integrated catalyst, the engines generate more than 80% fewer exhaust emissions.

The Kohler closed-loop EFI technology allows the PCV680LE to optimize performance by automatically adapting to operating conditions, while providing automotive-like turnkey starting and reduced maintenance, Kohler said.

Maintenance and Service

Kohler has developed new Kohler Pro 10W-50 oil and Kohler Pro Extended Life oil filters which, when paired together, triple the oil change interval from 100 to 300 hours in Kohler gasoline engines.

The company is offering three convenient Kohler Pro 300 Hour Oil Change Kits, consisting of Kohler Pro 10W-50 full synthetic oil and Kohler Pro Extended Life oil filter, to service most Kohler engines.

Kohler Pro 10W-50 is a full synthetic oil engineered specifically for extended oil change intervals on Kohler gas engines. The proprietary formulation is shear-stable with high-film-strength to provide extended wear protection, with a more durable fluid film than conventional oils.

The new Kohler Pro Extended Life oil filters are a durable construction for longer life. They incorporate 10-micron fiberglass media supported by wire backing to provide extra capacity with improved filtration, metal end caps and an anti-drain back valve to ensure oil flow in all conditions. The filter is available in two sizes, depending on the Kohler engine model.

Kohler also upgraded its CheckApp smartphone application for the monitoring and maintenance of Kohler engines with the addition of a digital shop for Kohler genuine parts. The Kohler Checkapp is free and available on both Android- and iOS-operated cell phones and tablets.

KUBOTA ENGINE AMERICA CORP.

Kubota Engines

Lincolnshire, Illinois, USA

Web: www.kubotaengine.com

Power Range

Diesel: 6 hp to 306 hp

Gaseous Fuel: 24 hp to 93 hp

Gasoline: 24 hp to 87 hp

Distribution News

Anderson Industrial Engines Co, Inc. (AIE) has expanded its distribution of Kubota engines and generators to cover Alaska, Oregon and Washington. AIE has been an authorized Kubota engine distributor since 1983. Its area of responsibility for Kubota industrial engines now covers Alaska, California, Colorado, Hawaii, Idaho, Iowa, Kansas, Montana, Nebraska, Nevada, Oregon, Utah, Washington, Western Missouri and Wyoming.

New Engines

Kubota unveiled the newest member of its Super Mini diesel engine range. With a maximum rated output of 24.8 hp (18.5 kW) at 3600rpm and a maximum torque output of 41.4 lb.ft. (56.1 Nm) at 2600rpm, the new D902-K is the company’s first diesel under 25 hp to employ an all-new proprietary combustion system incorporating a high-pressure common rail fuel injection and full electronic controls.

Engineered as a drop-in replacement for the broad range of machines using Kubota’s mechanically controlled D902, the D902-K meets EU Stage 5 and US EPA Tier 4 final exhaust emissions regulations without requiring aftertreatment. It also conforms to emissions and black smoke regulations in China.

MAN ENGINES & COMPONENTS

MAN Engines

Pompano Beach, Florida, USA

Web: www.man-mec.com

Power Range

Diesel: 147 hp to 1972 hp

Gaseous Fuel: 49 hp to 737 hp

Marine Engines

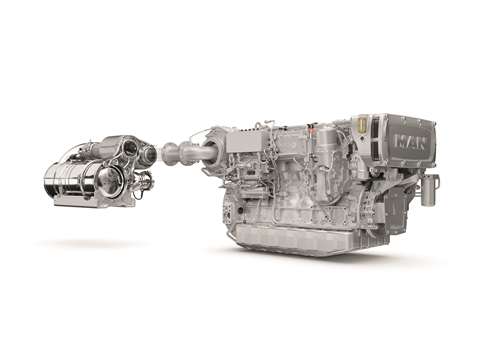

MAN Engines has added four power ratings, In addition to the existing six-cylinder in-line engines, which extend the range from the current 394hp to 1200 hp. The additions to the portfolio are two 24.2 L vee-configuration, 12-cylinder D2862 engines rated 1000hp or 1200hp. In addition, there are two 12.4 L six-cylinder inline engines rated 500 hp and 560 hp.

The six-cyclinder MAN D2676LE engine is (rated 389 hp, 444 hp, 493 hp, 552 hp and 591 hp, with aftertreatment.

The six-cyclinder MAN D2676LE engine is (rated 389 hp, 444 hp, 493 hp, 552 hp and 591 hp, with aftertreatment.

MAN Engines also added five additional power ratings at the lower end of its range for boat propulsion certified for IMO Tier 3 emissions regulations. The MAN D2676 engines are six-cylinder inline engines rated 389 hp, 444 hp, 493 hp, 552 hp and 591 hp.

The complete portfolio of MAN engines certified for IMO Tier 3 includes 12-cylinder vee-configuration engines and spans a range of power from 394 hp to 1650 hp for applications in working boats in light-, medium- and heavy-duty operations.

These include working boats such as ferries, crew transfer vessels, passenger boats, pilot boats and fishing boats, as well as sea rescue boats and patrol boats. The engines all incorporate MAN’s modular exhaust gas aftertreatment system (AGN), which relies on SCR and eliminates the need for DOCs or DPFs.

MAN Engines said its six-, eight- and 12-cylinder yacht engines have received type approval to the China Marine Recreational Stage 2 engine emissions standard which takes effect in July 2022. The company said it can now satisfy all the major engine emission standards throughout the world, including EPA Tier 3, IMO Tier 2 and RCD 2013/53/EC (EU Recreational Craft Directive).

MAN Engines has launched a new marine control unit combining a central electronics unit, bridge displays and a throttle lever. The MAN iSea bridge display has 5-inch and 7-inch color touch screen displays and can show engine operation and operating values, alarms, start/stop and convenience functions, including video. It replaces up to seven peripheral devices and has eight programmable digital inputs and one relay contact output.

Maintenance and Service

MAN Engines now offers a 24/7 service hotline for marine engines to provide easier access to its global service network. If servicing is required, owners and operators of yachts and workboats receive immediate assistance by calling +1 (754) 238-6313 in North and South America.

MITSUBISHI TURBOCHARGER AND ENGINE AMERICA INC.

Mitsubishi Engines

Itasca, Illinois, USA

Websites: www.mitsubishi-engine.com & www.mtea-us.com

Power Range

Diesel: 7.2 hp to 2923 hp

Gaseous Fuel: 603 hp to 2011 hp

Diesel Engines

Mitsubishi’s L and SL line of EPA Tier 4 compliant diesel engines incorporate mechanical/electronic governors and atmospheric pressure sensors, while EU Stage versions continue to be supplied with mechanical governors.

The small diesel engine product line includes the 0.635 L L2E constant speed engine rated 6.9 hp at 1800rpm, which meets Tier 4 final emissions regulations with a mechanical governor. The 0.952 L L3E variable speed engine is rated 16.8 hp at 2400 rpm, while the L3E constant speed is rated 12 hp at 1800 rpm.

The 1.319 L S3L2 variable speed diesel is rated 24.6 hp at 2500 rpm, while the constant speed version is rated 19 hp at 1800 rpm. The 1.50 L S4L2 constant speed engine is rated 24.6 hp at 1800 rpm. The 1.655 L D03CJ variable speed engine is turbocharged and charge-air cooled. Rated 36 hp at 2500 rpm, it also incorporates common rail fuel injection technology, along with a DPF and DOC, but without EGR. The 3.331 L D04EG engine will be available with two ratings, 48.2 hp for the naturally aspirated version and 72.4 hp for the turbocharged/charge-air cooled engine.

Distribution News

Mitsubishi Engines announced its selection of a new marine engine distributor for the US West Coast. Cascade Engine Center, headquartered in Seattle, Washington, is now the authorized Mitsubishi distributor for marine engine products for Alaska, California, Hawaii, Oregon and Washington.

Marine Engines

Mitsubishi introduced a new mechanically controlled heavy-duty marine propulsion engine in the second half of 2020. The Mitsubishi S12R Tier 4 is a 49 L, V-12, 1260 hp marine propulsion engine operating at 1600 rpm.

The engine utilizes SCR technology in meeting the NOx Tier 4 emission requirements. Mitsubishi also announced the delivery of upgraded S16R2-T2MPTAW engines – from IMO Tier II to IMO Tier III NOx limits – for a ferry hybrid propulsion system. The engines are teamed with a pair of electric motors rated 950 kW driving azimuth thrusters.

Natural Gas Engines

Mitsubishi said its 30 L, six-cylinder GS6R2 gas engine offers best-in-class efficiency at 42%. The company’s Miller-cycle engines offer outputs from 450 kW to 1500 kWe, operating at 1200 rpm for extra longevity and efficiency. The engines are equipped with two-stage intercoolers, improving thermal efficiency more 10% over single stage intercooled engines.

Tailored for power generation and combined heat and power (CHP) applications, the GSR engines combine advanced lean-burn pre-chamber combustion technology, custom-matched Mitsubishi turbochargers, and in-house developed control system. Selected models offer 0.5g/kWh NOx emission capability without SCR and 85% total efficiency in CHP applications.

ORIGIN ENGINES

Origin Engines

Kearney, Nebraska, USA

Website: www.OriginEngines.com

Power Range

Gaseous Fuel: 35 hp to 670 hp

Gasoline: 35 hp to 174 hp

Corporate News

Origin Engines announced in late 2020 its exclusive licensing agreement with Tecogen Inc. to utilize Tecogen’s patented Ultera aftertreatment emissions system. The Ultera technology is designed to reduce engine criteria emissions to near zero values, which can make an internal combustion engine – gasoline, natural gas or propane – competitive with fuel cells from an emissions perspective.

New Engines

Origin Engines has introduced a new inline 3.6 L engine to its lineup. The new four-cylinder will be offered in natural gas, propane and gasoline configurations and will bookend the company’s portfolio of industrial engines which include 4.3 L, 5.7 L, 6.2 L, 8.0 L, 9.1 L, 10.3 L and 24 L displacements.

The Origin 6.2 L spark-ignited engine is available in either naturally aspirated or turbocharged versions.

The Origin 6.2 L spark-ignited engine is available in either naturally aspirated or turbocharged versions.

All of the engines are available in naturally aspirated or turbocharged configurations, which provides a high degree of flexibility, and all are emissions certified for prime power and standby applications.

Origin will soon introduce its 24 L V-12, the first product to market since the announcement of the exclusive distribution agreement between KOEL Americas Corp. the wholly-owned US subsidiary of Kirloskar Oil Engines Ltd (KOEL) and Origin Engines. As part of the agreement, Origin will gasify Kirloskar’s 16 L V-8, 20 L V-10 and 24 L V-12 diesel engines.

Origin Engines also has a partnership with E-Controls Inc., a supplier of complete engine control and fuel delivery solutions for spark-ignited engines.

Origin Engines are manufactured in Kearney, Nebraska, and engineered specifically for industrial use in applications such as prime and standby power generation, agricultural pumps, forestry equipment, industrial power units, mobile industrial machinery plus oil & gas.

PERKINS ENGINES COMPANY LIMITED

Perkins Engines

Peterborough, England

Web: www.perkins.com

Power Range

Diesel: 5.3 hp to 2793 hp

Distribution News

Perkins recently announced that Georgia-based Pathfinder Power Solutions has been appointed the authorized Perkins distributor for the Southeast region of the US. Pathfinder will provide engineering, parts, sales, service and support in Alabama, Arkansas, Florida, Georgia, Louisiana, Mississippi, North Carolina, South Carolina and Tennessee.

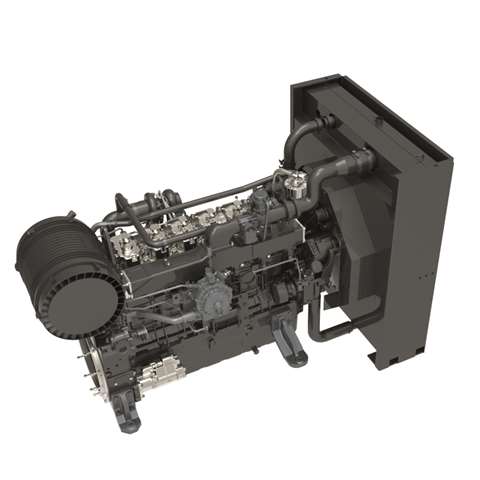

New Engines

Perkins announced their North American launch of the Series 5000 diesel in early 2021, its most powerful line of electronic engines to date, designed to deliver up to 1500 kWe emergency standby power for a range of critical applications including commercial buildings, data centers and hospitals.

The powerful Perkins 5000 Series generator drive engines were announced in early 2021 for the North American market.

The powerful Perkins 5000 Series generator drive engines were announced in early 2021 for the North American market.

The first engine available, the 5008C-E30TAG, is an inline eight-cylinder diesel with bore and stroke dimensions of 160 mm x 190 mm and a total displacement of 30.56 L.

Engineered to meet EPA Tier 2 standards for 60 Hz emergency standby applications, the engine has a gross mechanical output of 907 kWm to 1107 kWm (1216 hp to 1485 hp) and are targeted toward 900 kWe and 1000 kWe standby nodes.

Twin turbocharged and air-to-air charge-air cooled, the 5000 Series engines incorporate optimized turbochargers that provide load acceptance meeting ISO 8528-5 G2 and G3 standards and the ability to accept NFPA 100% block load.

On the industrial engine side Perkins offers a broad range of engines designed to meet EU Stage 5 and EPA Tier 4 final emissions standards. The line includes 14 different industrial engine platforms from 0.5 L to 18 L delivering 11 hp to 800 hp.

Stage 5 technologies used on these engines include common rail fuel systems – DOC, DPF and SCR – that incorporate an automatic regeneration process, which provide no interruption to the machine or operator.

To provide a collaborative approach with its customers, the Perkins Customer Machine Engineering Team (CMET) offers machine manufacturers the chance to create an upgraded or new product that takes advantage of hundreds of years’ worth of hands-on, real-world experience to expedite the development process.

POWER SOLUTIONS INTERNATIONAL (PSI)

PSI Engines

Wood Dale, Illinois

Web: www.psiengines.com

Power Range

Diesel: 830 hp to 2480 hp

Gaseous Fuel: 10 hp to 2000 hp

Gasoline: 20 hp to 500 hp

New Engines

PSI continues to expand its product offerings to the power generation and industrial sectors. This year it will introduce a range of new natural gas engines to its portfolio. New 4.5 L, 6.7 L, 10 L and 13 L engines will be available for power generation and industrial applications, while a new 17 L engine is targeted toward power generation.

New PSI 10 L engines will be available for power generation and industrial applications.

New PSI 10 L engines will be available for power generation and industrial applications.

PSI also recently introduced an 8.8 L gasoline engine to its industrial product line, calling it “one of the most robust and powerful engines of its kind.” The new engine is available in ratings up to 246.9 bhp (183.4 kW) with 498.8 lb.ft. (664 Nm) of torque.

The company is also continuing to develop its 8.8 L natural gas engine for power generation applications, with more information to be available later. PSI’s diesel line, which includes 32 L, 40 L, and 53 L engines, has been certified by the EPA for emergency standby applications.

The company’s industrial products offer ratings from 35 hp to 250 hp in fuel-agnostic solutions covering gasoline, liquid propane and natural gas.

PSI’s industrial engine line includes 0.998 L, 2.0 L, 2.4 L, 4.3 L, 5.7 L and 6 L engines used in forklifts and material handling, aerial lifts, agricultural and turf, arbor care, commercial mowers, off-road and utility vehicles, industrial sweepers, irrigation, ground support and construction equipment.

PSI credits its growing portfolio to its strategic investment and collaboration agreement with Weichai America Corp., a wholly-owned subsidiary of Weichai Power Co., Ltd.

Headquartered in Weifang, Weichai is one of the largest automotive component and power system suppliers in China. Since the start of the collaboration in 2017, PSI has access to Weichai’s manufacturing facilities and supply chain network, and both companies share best practices in engine research and development, as well as manufacturing, procurement and distribution.

ROLLS-ROYCE SOLUTIONS AMERICA, INC.

Rolls-Royce Engines

Novi, Michigan, USA

Web: www.mtu-solutions.com

Power Range

Diesel: 100 hp to 13,410 hp

Gaseous Fuel: 40 hp to 3487 hp

Alternative Fuels

Rolls-Royce announced in January 2021 that it would supply two mtu 16V 4000 M55RN gas engines to Sembcorp Marine Integrated Yard for the construction of the world’s first liquefied natural gas (LNG)-hybrid powered tug, which will be operated in Singapore once completed. The new LNG-hybrid tug is the first of a dozen that Sembcorp Marine plans to design and build to replace the existing diesel-powered tugs between now and 2025.

The main propulsion system of the tug comprises twin 16-cyclinder mtu Series 4000 gas units, which will provide a combined total power of 4001 hp at 1600 rpm.

Equipped with multipoint fuel injection, dynamic engine control and enhanced turbocharging, the new gas engines are able to deliver performance comparable to a high-speed diesel engine, the company said, while generating emissions considerably below the current IMO III limits without the need for exhaust aftertreatment.

At the company’s Germany site in Friedrichshafen, Rolls-Royce engineers are working on ways to exploit hydrogen as the fuel of the future with CEO Andreas Schell convinced that hydrogen has a key role to play in the green energy revolution. A demonstration emergency power generator using fuel cell technology from Daimler is expected to go live in mid-2021.

Company developers are also working on hydrogen engines and engines using methanol based on climate-neutral produced hydrogen.

Corporate Developments

The former MTU America Inc. was known as Rolls-Royce Solutions America, Inc. since the beginning of 2021. Rolls-Royce is the corporate brand and the employer brand. The brand name that customers are familiar with, mtu, is used to identify the company’s products and solutions. The former MTU Onsite Energy brand for decentralized power supply systems has since been integrated into mtu.

The core business featuring mtu propulsion and drive solutions for vehicles – from combine harvesters to mining machines – and ships is pulled together under the title “Mobile Power Solutions.” All activities involving diesel and gas engine-powered power plants, from combined heat and power plants to emergency power supplies for safety-critical facilities, will come under “Stationary Power Solutions” – as will all products and services related to oil & gas.

The new “Sustainable Power Solutions” unit will manage all existing and future technologies, from energy storage containers and fuel cells to the production and use of synthetic fuels.

The task of the “Power Solutions for Greater China” unit will be to continue to develop the growing markets in China. The new organization is the next logical step in the company’s PS 2030 strategy, which Rolls-Royce Power Systems has been consistently implementing since 2017.

Rolls-Royce announced in October 2020 a US $13.9 million investment in its Power Systems business unit for the addition of a new research and development building and multi-phase expansion of its mtu power generation manufacturing facility in Mankato, Minnesota.

The main portion of the expansion is the addition of 28,000 sq. ft. to the facility’s existing assembly hall, allowing for additional assembly lines, enhanced product testing capabilities and the creation of 20 new manufacturing positions.

Rolls-Royce announced in February 2021 that it was expanding the portfolio of the mtu brand to include UPS systems following its acquisition of Kinolt in 2020.

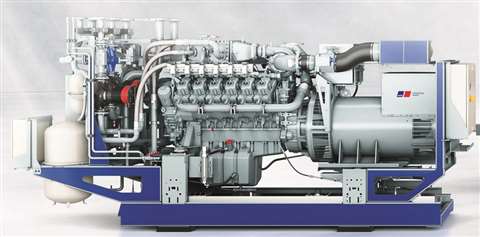

New Engines

Rolls-Royce in early 2021 received USA EPA Tier 4 certification for mtu propulsion systems based on its Series 4000 M65L 16-cylinder diesel engines.

Rolls-Royce launched a 50 Hz version of its mtu Series 500 gas engine for power generation applications in late 2020.

Rolls-Royce launched a 50 Hz version of its mtu Series 500 gas engine for power generation applications in late 2020.

The company reduced NOx emissions by 75% compared to IMO II requirements and particulate emissions by 65% compared to EPA 3, without the use of a diesel particulate filter.

Fuel consumption has also been reduced compared to the previous generation of engines engine power has been increased up to 214 hp per cylinder.

Rolls-Royce launched a 50 Hz version of its mtu Series 500 gas engine for power generation applications in late 2020.

With a power range of 250 kW to 550 kWe and peak efficiencies of up to 42.6%, these gas generator sets and cogeneration sets can be ordered with six-cylinder inline engines as well as eight- and 12-cylinder V-engines for the 50 Hz market. The Series 500 will be available for 60 Hz markets in mid-2021.

Rolls-Royce introduced the mtu Series 4000 G05 generator set as a fully integrated power solution that provides direct coupling of the engine and aftertreatment for optimized emissions performance, in February 2021. Powered by 12V Series 4000 engines, the gen-sets come in four ratings for 60 Hz standby applications.

New Ratings

Rolls-Royce announced in September 2020 that its mtu high-performance yacht engine had received a power upgrade, increasing the output of the 12-cylinder series 2000 M96 engine from 1920hp to 1972hp. The acceleration characteristics, excellent maneuverability and quiet operation of the engine make it especially suited to luxury yachts and leisure fishing boats, the company said.

Rolls-Royce received EPA Tier 4 certification, for its mtu propulsion systems based on its Series 4000 M65L 16-cylinder diesel engines, in March 2021.

SCANIA USA, INC.

Scania Engines

San Antonio, Texas, USA

Website: www.scaniausa.com

Power Range

Diesel: 275 hp to 770 hp (industrial)

Diesel: 220 hp to 1150 hp (marine)

Industrial Engines

Scania continues to offer Tier 4 final and EU Stage 4 compliant, 9 L, 13 L, and 16 L industrial engines which are found in a variety of North American segments, including agriculture, airport products, construction, forestry, material handling and stationary. The output ranges for the Scania industrial engines include 275 hp to 400 hp for the 9 L, 350 hp to 550 hp for the 13 L and 550 hp to 770 hp for the 16 L.

Scania’s power generation line for Tier 4 final consists of 9 L (208 kWe to 240 kW), 13 L (264 kWe to 328 kWe) and 16L (320 kWe to 400 kWe), all rated for 60 Hz prime power applications. Scania currently offers engine versions that meet EPA Tier 4 final, EU Stage 4, Stage 3A and Stage 2 compliance for industrial applications.

Marine Engines

Scania launched a range of powerful and lightweight and fully emissions-certified range of marine diesels for the US pleasure craft market. The line consists of the DI13 304M 13 L inline engines from 700 hp to 900 hp, along with 16 L DI16 V-8s ranging from 1000hp to 1150 hp, all of which are targeted toward vessels built in or exported to Canada and the US.

The Scania Marine DI16s offers the simplicity of a single wastegated turbo per bank.

The Scania Marine DI16s offers the simplicity of a single wastegated turbo per bank.

The DI13 engines, which are available in a 925 hp rating for export, have as much as a 22% higher power to weight ratio than competitive 13 L 900 hp offerings.

The DI16s offer the simplicity of a single wastegated turbo per bank, without the need for twin turbo, multi-stage turbo or supercharged/turbocharged systems.

The resulting light weight, also the result of a compacted graphite iron (CGI) engine block, combined with Scania’s proprietary Engine Management System (EMS) and XPI common rail fuel injection system (XPI), helps optimize fuel delivery for higher torque, lower noise and improved fuel efficiency. The new engines meet EPA’s Tier 3 recreational standard for marine diesel engines.

Corporate News

Scania Engines has been rebranded Scania Power Solutions to reflect the widening range of power options Scania offers and the capabilities of its marine, industrial and power generation engines range.

The move comes at a key moment as the company continues its journey toward electrification, where new types of motive power including electric motors and e-machines (electric motors plus their associated adjacent hardware) will progressively come to the fore.

Distribution News

Scania has announced a number of changes to its North American distribution network.

Hamilton Engine at Sun Prairie, Wisconsin, is the new distributor for Scania industrial engines in the Midwest region comprised Illinois, Iowa, the upper peninsula of Michigan, Minnesota, Missouri, North Dakot, and Wisconsin. Mack Boring & Parts Co., Scania’s East Coast distributor, will assume additional marine territory in the Great Lakes region, including Northern Illinois and Indiana, Iowa, Michigan, Minnesota, Northern Ohio and Wisconsin. The company also represents Scania Tier 4 final industrial engines for the East Coast and West Virginia.

Laborde Products Inc. is the new Scania marine distributor for the Gulf Coast and Inland Waterways regions consisting of Alabama, Arkansas, Kentucky, Louisiana, Mississippi, Missouri, Southern Illinois, Southern Indiana, Southern Ohio, Tennessee, Texas and West Virginia.

The existing industrial distributors of Collicutt Energy Services, Hamilton Engine and Loftin Equipment will expand their respective industrial territories to include areas in the West Coast region of the United States and Canada.

Electrification News

Scania has continued operational testing and development of its electrified power systems. The electric machine and power control unit draw on the company´s experience from electrifying its own on-road vehicles and will be modular and scalable with standard mechanical and system management interfaces.

Scania’s electric machine – which can be run either together with a combustion engine or as a standalone power provider (motor and/or all-speed dc generator) – has a compact design and a speed range adapted to that of the engine, eliminating the need for an additional reduction gear, in turn minimizing energy loss and facilitating equipment design and installation.

VOLVO PENTA OF THE AMERICAS

Volvo Penta Engines

Chesapeake, Virginia, USA

Website: www.volvopenta.com/en-us/

Power Range

Diesel: 13 hp to 1000 hp (marine)

Diesel: 143 hp to 700 hp (Tier 4 final industrial)

Gasoline: 200 hp to 430 hp

Industrial Engines

Volvo Penta continues to strengthen its presence in the industrial off-road market, supporting and onboarding customers in construction, materials handling, agriculture and forestry, raw material exploration and specialty applications.

The company reported steady growth in its North American power generation business, through its strategy of forming OEM relationships with major generator manufacturers in the region.

The Volvo Penta TWD1683 VE with aftertreatment is designed to be a durable and compact engine.

The Volvo Penta TWD1683 VE with aftertreatment is designed to be a durable and compact engine.

Volvo Penta’s new dual-frequency D8 engine for generator sets incorporate advanced diesel fuel injection and turbocharging systems in an inline six-cylinder platform. The new D8 diesels are available as Stage 2 and Stage 3a/Tier 3 emission levels with high power density, compact size, fuel efficiency and low noise levels.

Volvo Penta is also launching its new Tier 4 final/Stage 5 certified D16 six-cylinder inline off-road engine. The engines offer low- to high-end torque, high-altitude performance and as much as a 10% reduction in fuel consumption.

Designed as a durable, compact engine that’s easy to install and simple to maintain, it offers extended oil service intervals from 500 to 1000 hours.

Marine News

Volvo Penta revealed a host of new engines and services. This includes a new D16 IMO Tier III/U.S. EPA Tier 3 package that offers more power and greater durability, updated D13 engines, upgraded D8 and D13 engines to meet EU Stage V marine emissions for Inland Waterways and the Volvo Penta Inboard Performance System (IPS) and IMO III technology. The company plans to introduce a D8 IMO III for rating 1 and 2.

Volvo Penta unveiled its Assisted Docking technology at the virtual 2021 Consumer Electronics Show (CES). The system is designed to give vessel operators better control when docking by automating their intentions, compensating for some dynamic variables such as wind and current and helping the vessel stay on its intended course. At its debut, the technology was named a “Best of CES” finalist.

The company extended its Volvo Penta Easy Connect app to marine commercial professionals, as well as updating the current marine leisure offering. The Volvo Penta Easy Connect app is free and available on both Android- and iOS-operated cell phones and tablets.

Distribution and Service

Volvo Penta said it took a proactive approach to ensure reliable support for distributors, power centers, dealers and customers in the Americas’ region throughout the periods of shutdowns and uncertainties caused by the COVID-19 pandemic.

The company launched an online instructor-led training curriculum in spring 2021. As a result, Volvo Penta’s industrial and marine dealer technicians can be trained online in real-time by skilled technical trainers. The addition of the online training option led to an increase of 28% in the number of technicians trained over the previous year (1623 in 2019 compared to 2078 in 2020).

Volvo Penta’s parts distribution warehouse in Vancouver officially migrated in November 2020 to Volvo Group’s warehouse in Toronto for Canadian customers. This move provides a more centralized location, optimal delivery solution and higher fill rates for customers, as well as a synergized, more cost-effective solution for customers in Canada.

A more mature Order Management System (PartsLinQ DFS, which has been used since 2016) was implemented in the go live. The entire process was undertaken within a 10-month period during the height of the COVID-19 crisis. This was an important milestone for Volvo Penta’s parts business in the region, and one that was well received by partners based on feedback. A key Volvo Penta dealer has confirmed the fill rate for Q1 2021 in the new location is averaging 96.6%, compared to 94.6% in Q1 2020 in the same location.

YANMAR AMERICA CORP.

Yanmar Engines

Adairsville, Georgia, USA

Web: www.yanmar.com

Power Range

Diesel: 3.5 hp to 6437 hp

Dual Fuel: 1072 hp to 5686 hp

Gaseous Fuel: 60 hp to 85 hp

New Engines

Yanmar has continued to develop new engine products, including several models in its 4TN diesel range (73 hp to 208 hp) and low-fuel LPG series, all of which are engineered to comply with EPA/CARB Tier 4 and EU Stage 5 regulations.

The 1.57 L three-cylinder Yanmar 3TN diesel complies with EU Stage 5 and EPA/CARB Tier 4 emissions regulations.

The 1.57 L three-cylinder Yanmar 3TN diesel complies with EU Stage 5 and EPA/CARB Tier 4 emissions regulations.

The company unveiled two new liquid-cooled industrial engines in late 2020. The 3TN86CHT and 4TN86CHT both comply with EU Stage 5 and EPA/CARB Tier 4 emissions regulations.

The 3TN86CHT is a 1.57 L three-cylinder rated 53.7 hp with 145 lb.ft. of torque. The 4TN86CHT is a 2.09 L four-cylinder rated 74 hp, with 193 lb.ft. of torque.

Both engines incorporate common rail fuel systems, turbocharging and charge-air cooling resulting in greater power density, 20% and 14% higher than turbocharged TNV engines of the same displacement. They also incorporate a proprietary exhaust gas aftertreatment system consisting of a DOC and DPF, with the DPF designed for a maintenance interval of 6000 hours.

Yanmar has begun mass production of the vertical, water-cooled 4TN107 industrial engine that was first unveiled in 2019. The new engine has allowed Yanmar to triple its diesel power range (147 hp to 208 hp). While the engine was initially launched into the construction industry, Yanmar is gaining traction in other sectors, including the agricultural equipment industry. The 140 hp 4TN101 is being tested by several OEMs in various applications, slated for mass production in 2022.

Marine Engines

For leisure boats and light-duty commercial applications, Yanmar introduced two new common rail marine diesels – the 6LF and 6LT – for pleasure craft and commercial applications. The engines are available in ratings from 485 hp to 640 hp.

New Engine Ratings

Yanmar has announced new ratings for its TNV and TN engines. New TNV ratings include 118.5 hp at 2500 rpm for the 4TNV94FHT-NYEA2, 67.5 hp at 1800 rpm for the 4TNV98T-ZGGM, 28.9 hp at 1800 rpm for the 4TNV88-BGGES, 35.9 hp at 1800 rpm for the 4TNV84T-BGGES, 54.7 hp at 1800rpm for the 4TNV98-ZGGES, and 67.1 hp at 1800 rpm for the 4TNV98T-ZGGES.

New TN engine ratings include 114 hp at 2400 rpm for the 4TN101FHT, 140.8 hp at 2200 rpm for the 4TN101FDT, 147.5 hp at 2200rpm for the 4TN107FHT and 207.8 hp at 2200rpm for the 4TN107FTT.

New TN gas engine ratings are 60.3 hp at 2600 rpm for the 4TN88G and 84.4 hp at 2500 rpm for the 4TN98G.

Supporting documents

Click links below to download and view individual files.

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

CONNECT WITH THE TEAM