Thompson Adds New Wellpoint Pump Set

15 July 2020

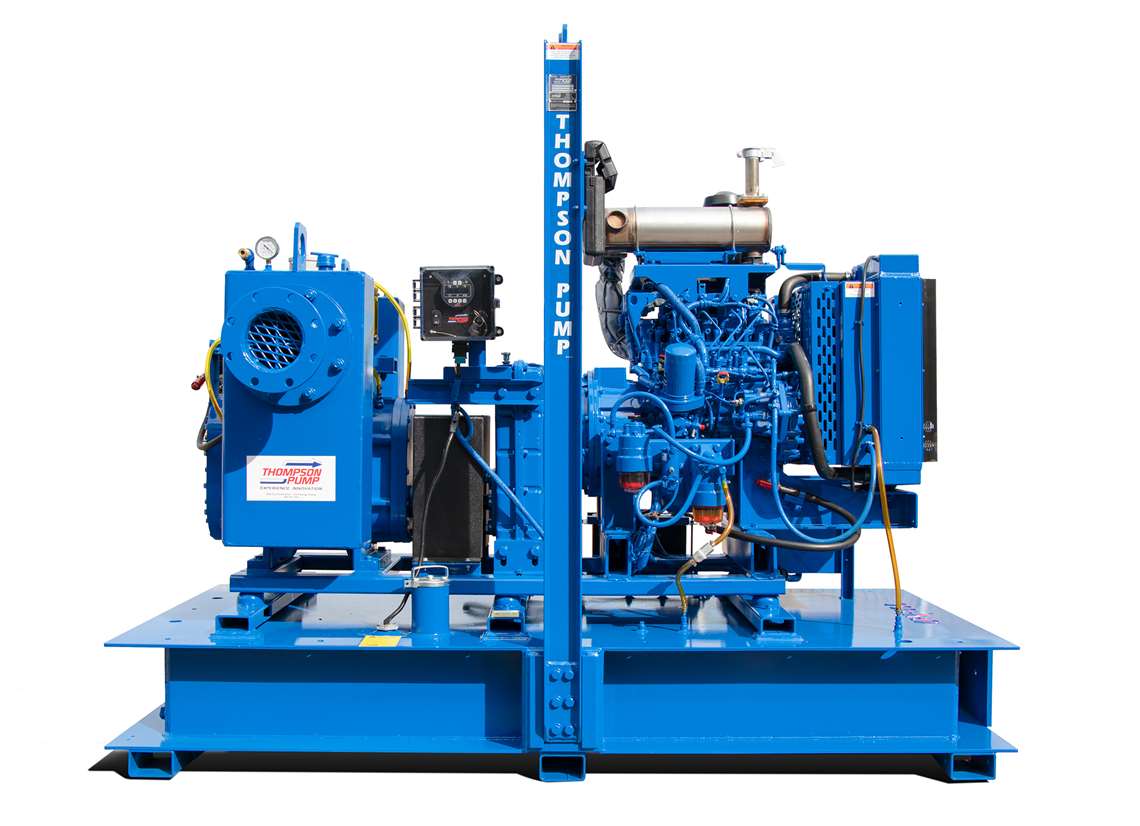

Thompson Pump and Manufacturing Co. the Port Orange, Fla., manufacturer of heavy-duty portable diesel and electric-powered dry prime and wet prime pump sets, that includes bypass and dewatering pumps, has added a 6 in. rotary wellpoint pump, the model 6RW-DIS-4LE2T-X to its RW range.

The new pump set debuted earlier this year and joins the company’s larger 8RW and 12R versions. The pumps are equipped with abrasion and corrosion resistant parts, polyurethane rotors, and stainless-steel wear plates designed to handle industrial and plant applications, the company said.

The 6RW adds to the lower end of the Thompson RW range with a six-inch model with heads up to 80 ft. and maximum capacity of 1400 gpm. By comparison, the eight-inch model 8RW has heads to 80 ft. and 2330 gpm capacity, while the 12-inch model 12R has heads to 120 ft. and 2200 gpm capacity.

“This 6 inch version was created, in part, due to the high demand to expand the rotary pump family’s dewatering capabilities,” said Chris Thompson, president of Thompson Pump and Manufacturing.

The pump end has a positive displacement, low-pulsation, self-priming, rotary lobe, with a four-lobe, single piece design rotor with carbon steel shaft and welded carbon steel fins with polyurethane coating. The rotor housing is heavy-duty cast aluminum.

All three RW/R models drive a rotary pump that can handle both air and water. The positive displacement with constant suction makes this pump applicable for wellpoint applications.

The 6RW pump is designed for wellpoint and sock dewatering applications and can be used in place of vacuum or piston pumps, making it a cost-effective dewatering option, Thompson said. In construction applications can include wellpoint and sock dewatering, remediation, dewatering of trenches as well as jack and bore pits, dewatering of elevator pits and foundation structures. In municipal uses, dewatering of sewer, gas, and water pipelines, lift stations and trench dewatering are typical uses.

Power for the 6RW is a turbocharged, four-cylinder, 2.2 L Tier 4 final Isuzu model 4LE2 diesel, with cooled EGR and diesel oxidation catalyst (DOC) aftertreatment. The engine is rated 40.2 hp at 1800 rpm constant and 48.3 hp at 2400 rpm constant.

The 8RW is powered by either a Deutz TD3.6L4 or a Kohler CK25KDI diesel. Both are rated 74 hp at 2400 rpm. The 12R also is powered by the Deutz TD3.6L4 at 74 hp/2400 rpm.

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

CONNECT WITH THE TEAM