First EVOLT eGR-250N RT delivered to Japanese customer to work on power plant project

Alison Trueblood previously led Fuel Cell and Hydrogen Technologies for Accelera

Vistor numbers down 26%, but successful focus on decarbonisation

One year on from Develon brand launch, Young-cheul Cho reviews its development

Demand in North America continues to be strong as JLG sees “continued demand drivers going forward”

New partnership adds locations across Indiana and Michigan for telehandler OEM

Sponsored Content

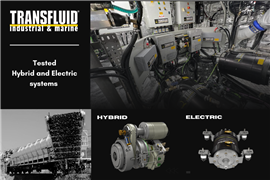

Efficiency in the marine, industrial and railway sectors: electric motors for silent propulsion and cost reduction. Hybrid propulsion Transfluid optimizes energy, costs and emissions. Breakthrough for sustainable and efficient mobility, reducing environmental impactElectric & Hybrid propulsions

In this second installment of a three-part series on what makes a facility “state-of-the-art,” we examine a philosophy related to cutting-edge plant floor technology: smart manufacturing.