Facility to supply fuses for EVs, data centers, renewable energy systems

Project to build on University of Nebraska-Lincoln’s long relationship with USDA

First pair of pure electric lifts are aimed at the EAME and Australian markets

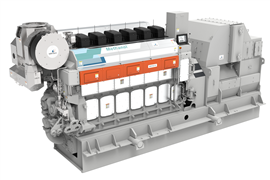

Three engine orders announced, including China’s largest methanol order for maritime

OEM reveals 2023 sales for construction and resource industries, and its highlights of the year

Sponsored Content

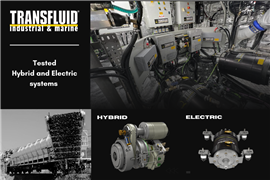

Efficiency in the marine, industrial and railway sectors: electric motors for silent propulsion and cost reduction. Hybrid propulsion Transfluid optimizes energy, costs and emissions. Breakthrough for sustainable and efficient mobility, reducing environmental impactElectric & Hybrid propulsions

In this second installment of a three-part series on what makes a facility “state-of-the-art,” we examine a philosophy related to cutting-edge plant floor technology: smart manufacturing.